17-00001-C Page | 52

Step 3: Non-conductive mode (continued)

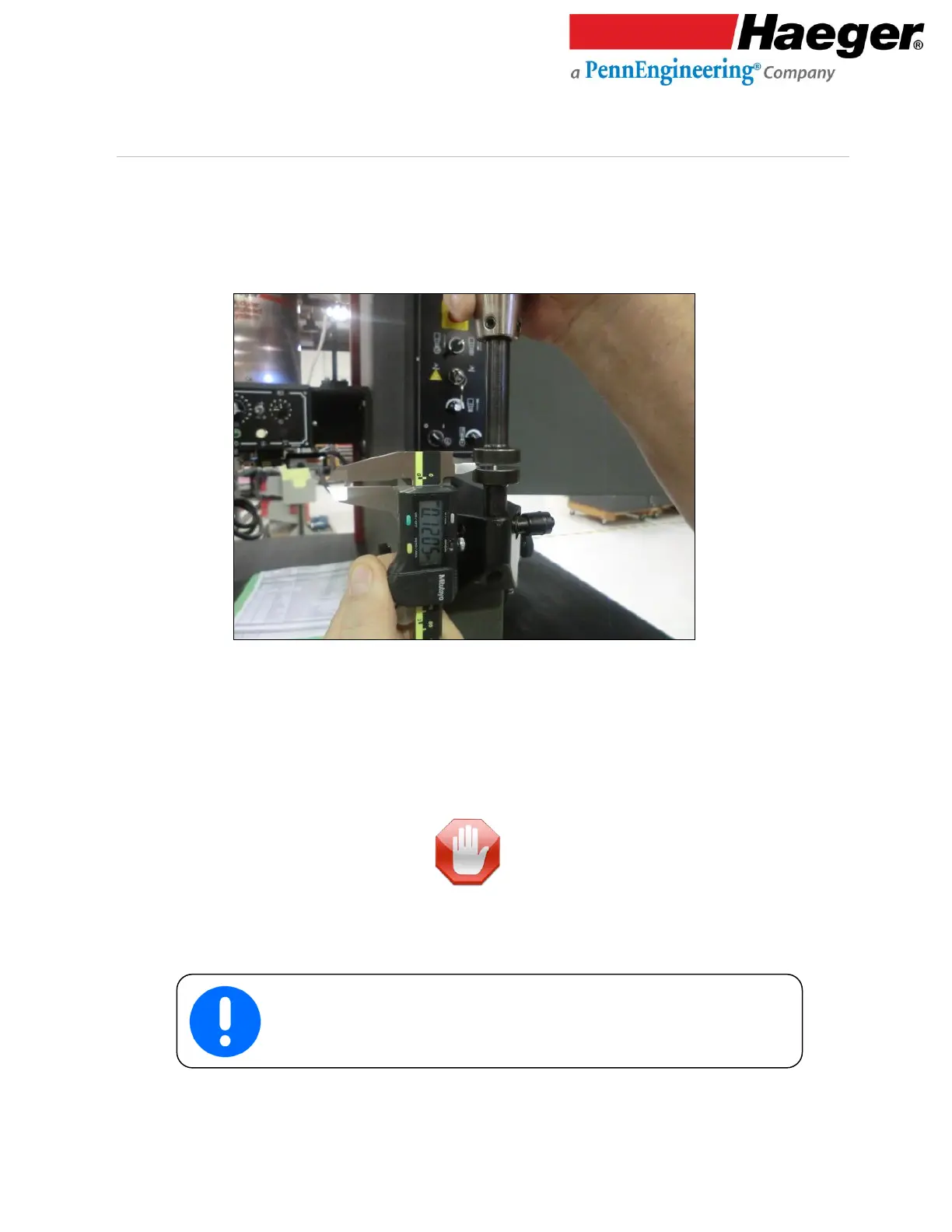

5. Carefully grasp the sides of the Upper Tool Holder and raise it until a positive stop position is

reached. With a calibrated measuring instrument (Digital calipers are best), measure the

vertical distance between the upper and lower Anvils. If this measurement is at least a

minimum of .060” in. /1.52 mm, go to Instruction 5.

a. If this dimension is less than.060” in. /1.52 mm, the Safety System has failed!

Immediately turn the machine off by pressing the red Off Switch and turning the Main

Disconnect Switch to the Off position. The machine’s Main Disconnect Switch must be

locked in the Off position until repairs are begun and follow Lock-out/Tag-out procedures.

Do not operate this machine until qualified personnel have repaired the machine and the

Non-Conductive Mode has been properly tested.

6. Next keep your hands away from the tooling area. Depress the Down Foot pedal switch a second

time. The machine should exert the pre-set 3,000 lb/13 Kn force to both upper and lower Anvils and

then return to its Up position.

If this machine completes the above sequence correctly, the test of

the Safety Switch and Safety System is complete and operating

properly.

Loading...

Loading...