CARBURETION

3.25

Mikuni TMX Carburetor Service

Carburetor Disassembly and Inspection

1. Remove water trap assembly from float bowl and inspect

O-ring, hose and clamp condition. Refer to exploded

view corresponding with carburetor being serviced.

2. Inspect enricher (choke) fuel supply passage in bowl for

obstruction.

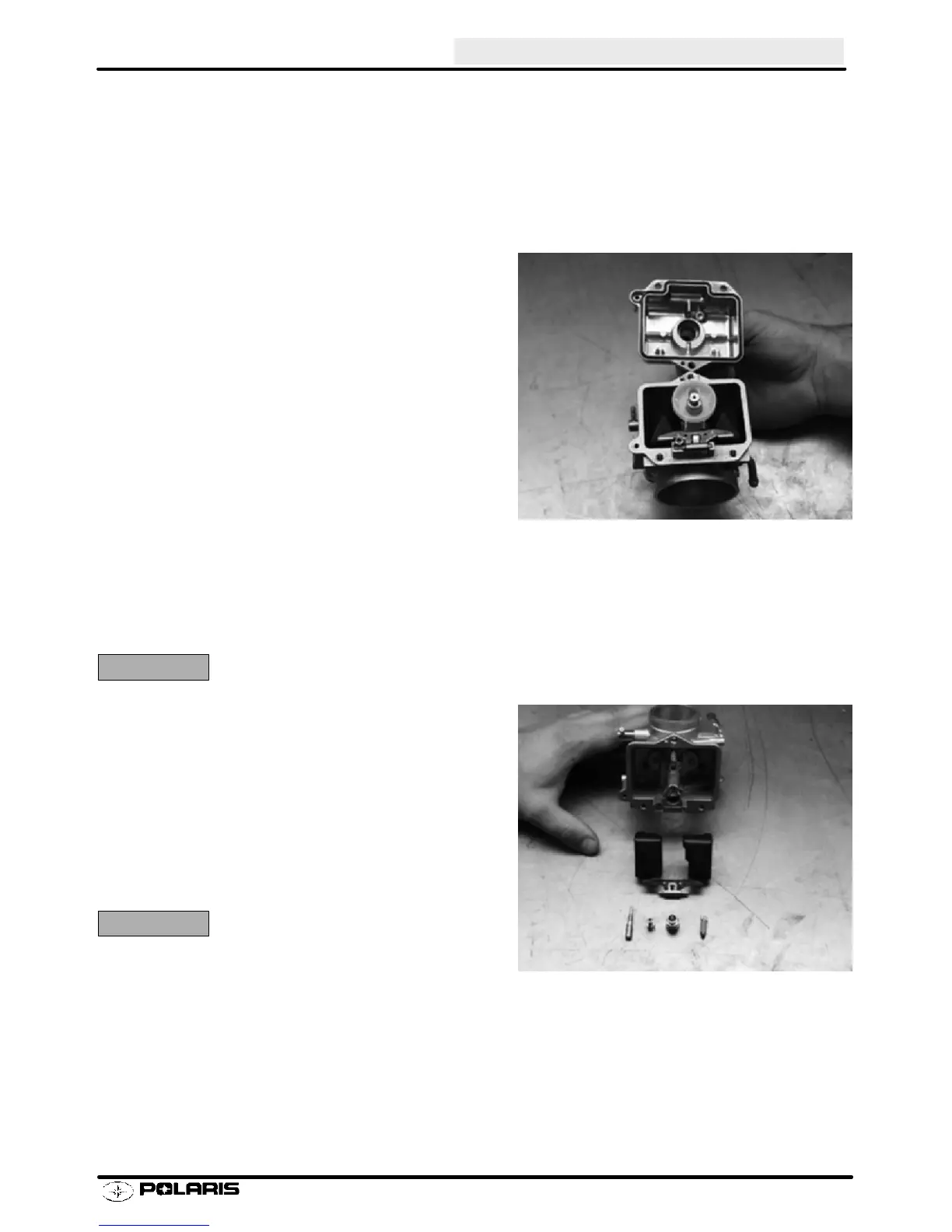

3. Use an automatic center punch to remove float arm pin.

Remove inlet needle and seat assembly.

4. Inspect needle for wear and replace sealing washers

upon reassembly.

CAUTION:

Do not bend float arm during disassembly. Support tower

casting when tapping pin out. Do not use excessive force to

remove float arm pin. The float pin tower castings are very

easily damaged and are not repairable.

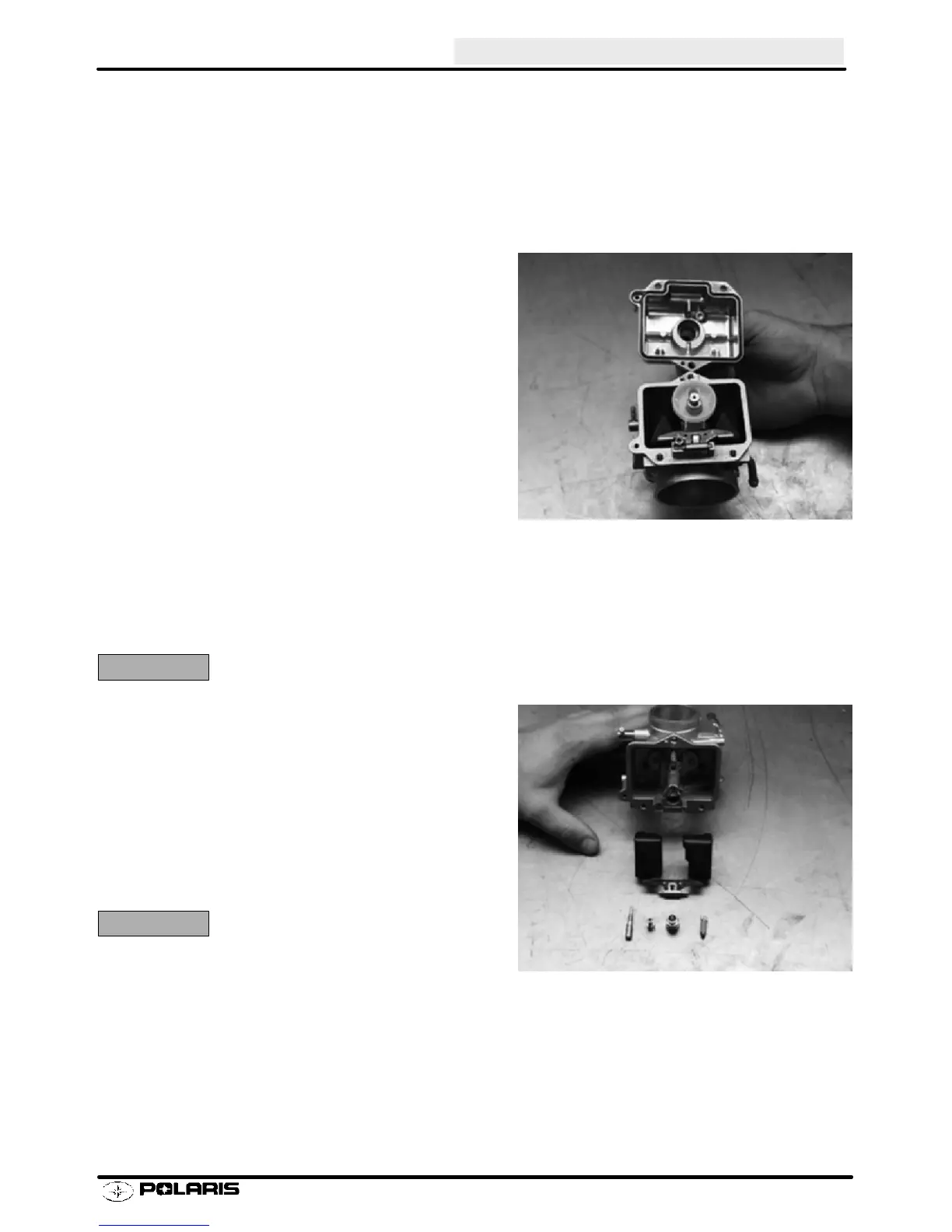

5. Remove main jet and washer (or spacer ring) and push

needle jet into the slide valve chamber to remove. Clean

air bleed hole in needle jet.

6. Remove pilot jet.

CAUTION:

Wear eye protection when using compressed air or cleaning

solvents. Review all fuel system warnings found on page

3.1 before proceeding.

7. Remove pilot air screw and clean all passages in the

carburetor body with carburetor cleaner. Dry all

passages and jets with compressed air. Replace

gaskets and any parts which show wear or damage.

8. Reassemble carburetor, adjusting float level before

installing float bowl.

Enfocus Software - Customer Support

Loading...

Loading...