CLUTCHING

4.44

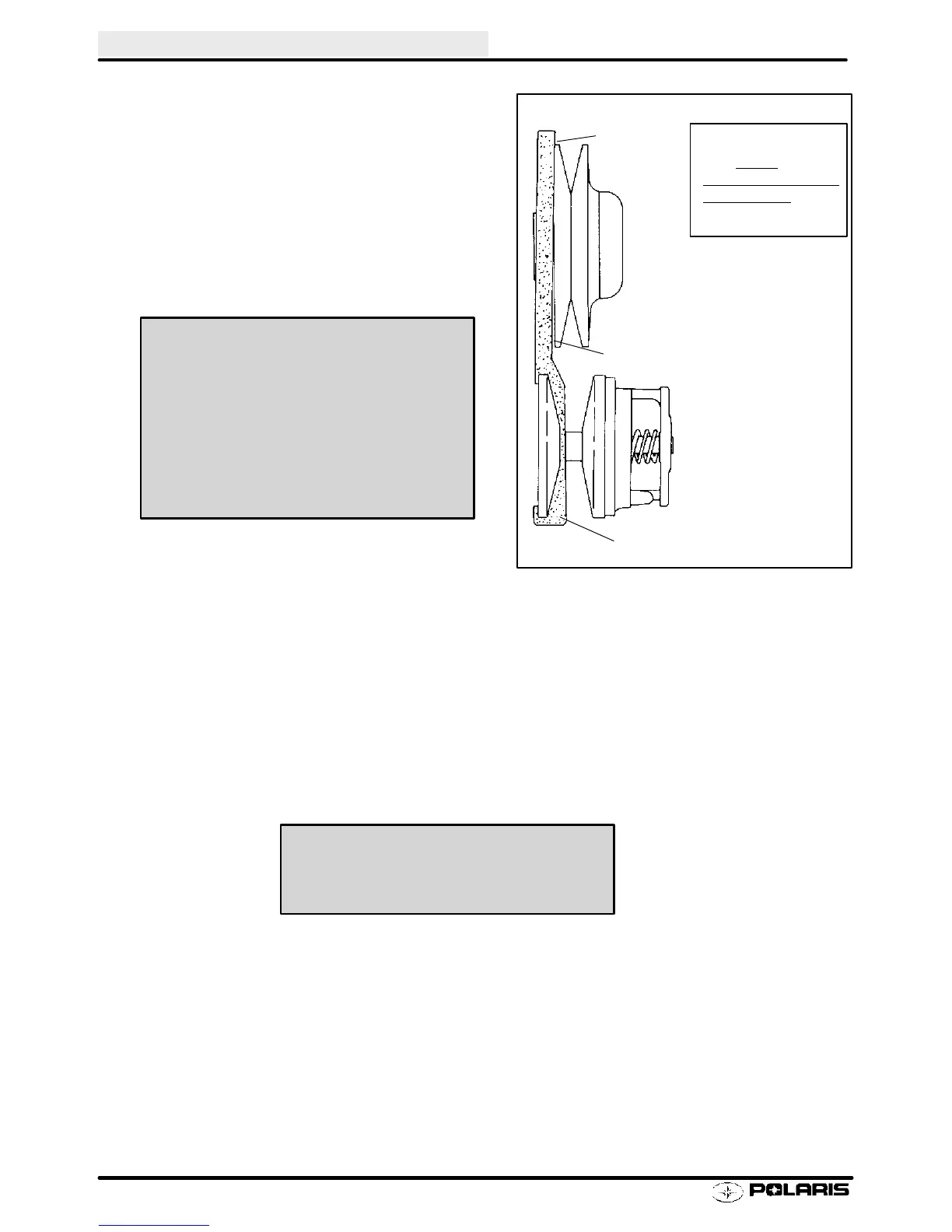

Clutch Offset Inspection (ALL)

NOTE: Proper offset aligns the fixed sheaves of both

clutch assemblies. This allows the clutches to be

aligned throughout the shift range.

1. Remove drive belt. Belt deflection adjustments

affect offset. Set belt deflection first.

2. Install proper alignment tool, depending on type of

clutch, as shown in Ill. 1.

3. Rear of driven clutch moveable sheave should just

contact tool when clutch is pushed inward on

jackshaft.

Clutch Offset Adjustment

1. Determine direction driven clutch needs to be adjusted. (Refer to Clutch Offset Inspection procedure above).

2. Remove driven clutch retaining bolt, and remove driven clutch.

3. Add or take out washers on jackshaft between the driven clutch and jackshaft bearing to achieve proper offset.

4. Most models require the driven clutch to float on the jackshaft. After adjusting offset, add or remove shim

washers from the retaining bolt to provide a .040s-.100s (1-2.4mm) of float on jackshaft. This will prevent side

loads on the jackshaft bearing.

Driven Clutch Bolt Torque -

15 ft. lbs. (21 Nm)

Offset Alignment Tool

5/8s Of

fset

All models with

P85

driven

clutch

NOTE:Upto.060s (1.5mm)

air gap allowed at point “B”.

Up to .125s is acceptable on

new machines.

Ill. 1

Offset - Non-Electric Start Models

A

B

No gap at

point “A”

Clutch Alignment (Tools) -

P85 - 5/8sOffset (PN 2870426)

Enfocus Software - Customer Support

Loading...

Loading...