ELECTRICAL

8.6

CDI Ignition Timing

Timing Procedure - All Models

NOTE: Always verify timing of engine at room temperature only (68q F/20q C, no engine warm up) and at the

proper RPM.

1. Refer to the timing specification charts at the beginning of this section to determine the proper ignition timing

for the engine you are working on.

2. Use a dial indicator to place the piston in the proper timing position and mark the flywheel at this point.

3. Connect an accurate tachometer and a good quality timing light to the engine according to manufacturer’s

instructions.

Disconnect the TPS (Throttle Position Sensor) connector from carburetor.

4. Start engine and increase RPM to the point

specified in the timing specifications in Chapter 1.

Hold the throttle to maintain specified timing

RPM.

5. Point the timing light at the timing inspection hole.

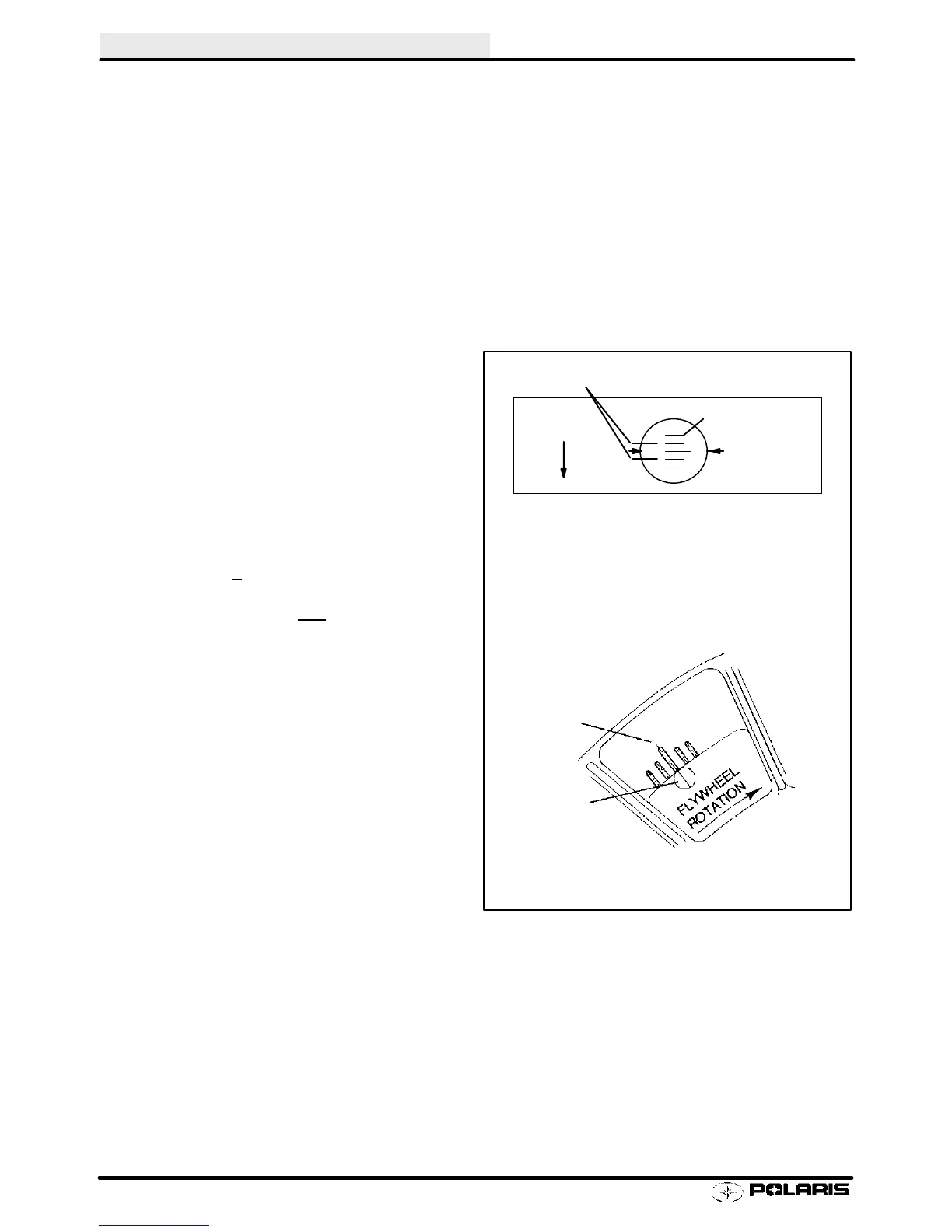

6. With your head positioned so there is a straight

line between your eye, the stationary pointer and

the crankshaft center line, note the relative

position between the marked flywheel line and the

stationary pointer. If the stationary pointer is

aligned with the mark made in Step 2, (or within

the acceptable +

variance) the timing is correct.

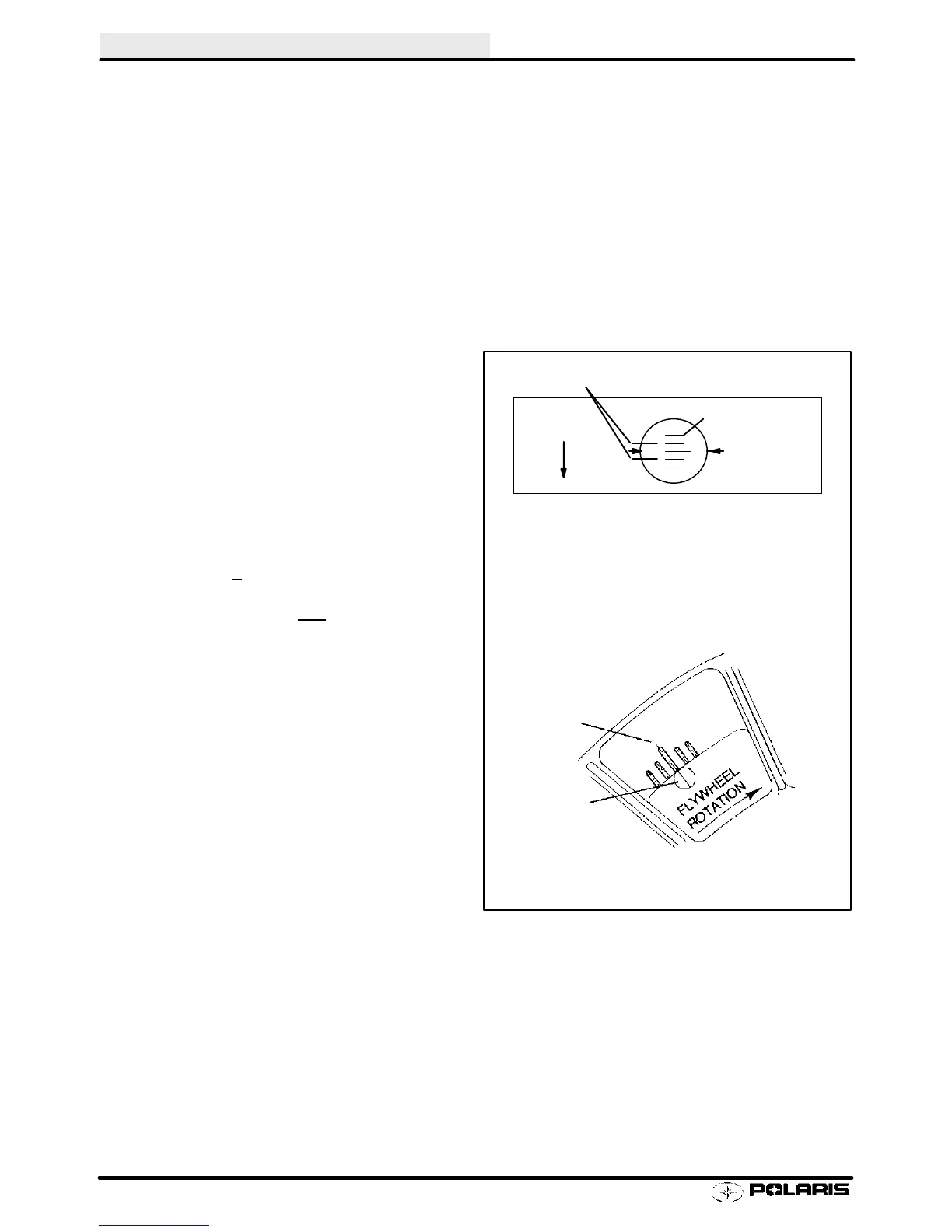

7. If the pointer is outside the variance, the stator will

have to be rotated either with

crankshaft rotation

(to retard the timing) or

against

rotation to

advance it.

NOTE: Rotate stator plate approximately the same

distance as the marks must move.

NOTE: In most cases, the recoil starter housing, re-

coil drive hub, and flywheel must be removed to loos-

en the stator bolts and change the timing. On some

engines, the stator plate retaining screws can be ac-

cessed through the flywheel.

8. Torque stator plate screws and flywheel nut to

specified torque. Apply Loctite 262 (red) to

crankshaft flywheel taper if required. Refer to the

Specifications section for torque specifications

and flywheel installation procedure for engine

type.

Flywheel

Rotation

Acceptable Variance

Flywheel Lines

Stationary

Pointers

NOTE: Acceptable variance is usually

one line on either side of the dial indicated

timing mark.

Blower Housing

Stationary

Lines

Flywheel

Mark

Liquid Cooled

Fan Cooled

Enfocus Software - Customer Support

Loading...

Loading...