CLUTCHING

4.20

Spider Indexing

NOTE: Spider indexing affects clutch balance and belt

to sheave clearance. Read procedures carefully before

proceeding.

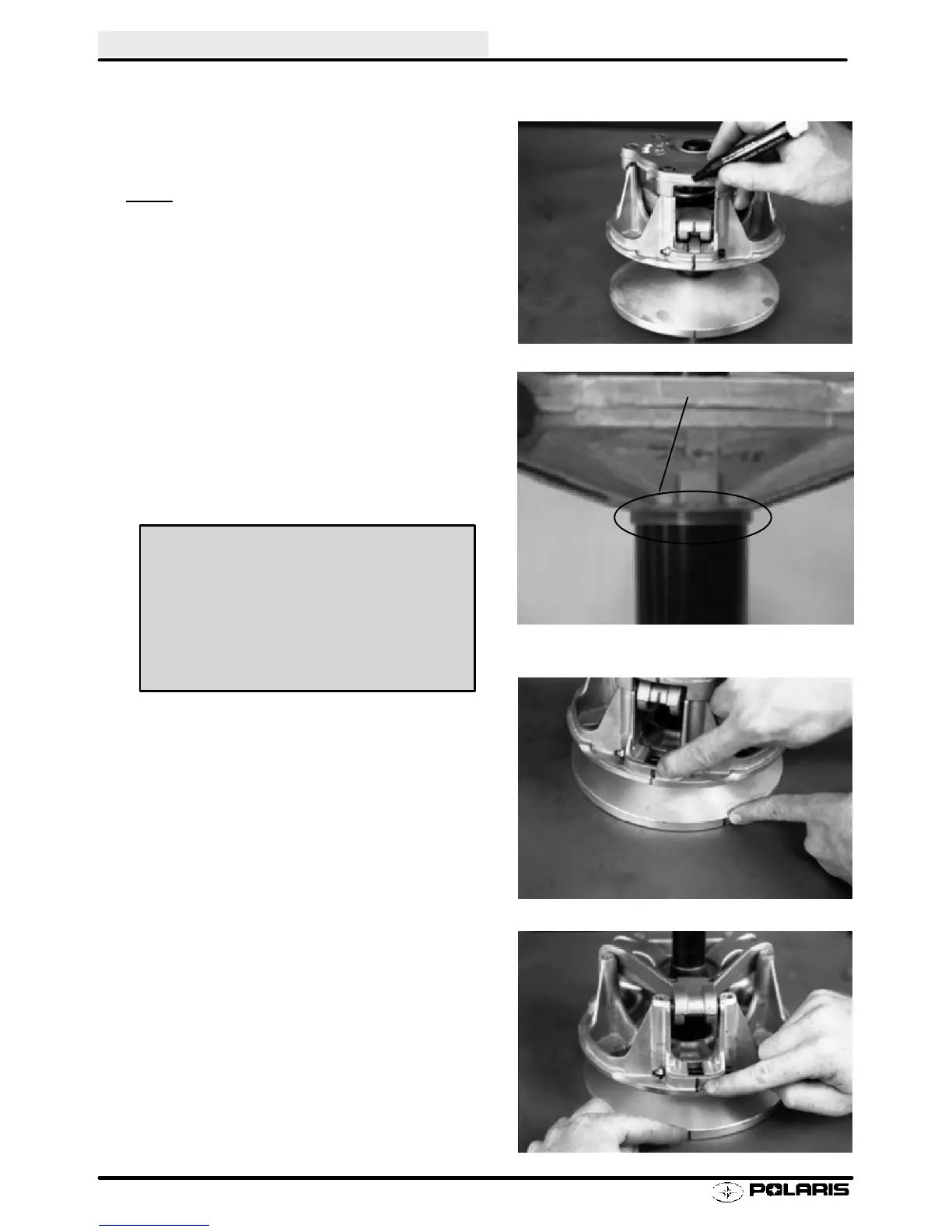

1. Before

disassembling drive clutch, mark spider,

cover, moveable sheave, and stationary sheave in

line with a permanent marker as shown.

2. Disassemble drive clutch as described on page

4.20-4.21. Take care to note the amount and

thickness of the shim washers under the spider.

3. Add or remove spider washers as required to

achieve desired belt to sheave clearance.

S For example: If belt to sheave clearance is .020s

too large, removing one .020s shim will position

the movable sheave closer to the fixed sheave

reducing belt to sheave clearance by .020s.

NOTE: The following washers are available for fine tuning:

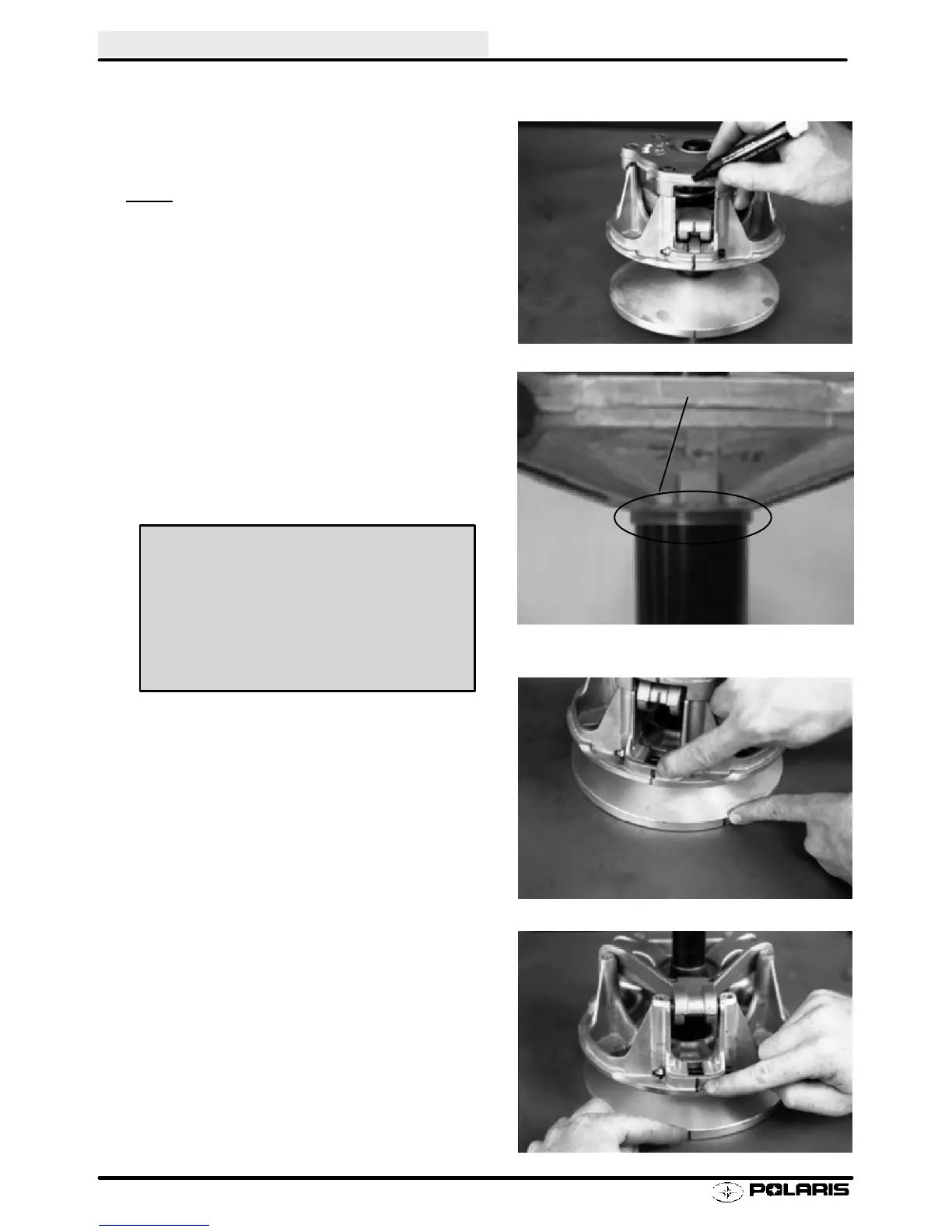

4. Install spider washer(s) and spider aligning Xs.

Notice as the spider seat location is changed, the

sheave marks made before disassembly no longer

align. There are two ways to bring the sheave marks

into alignment.

S Vary the amount and thickness of spacer washers

(Washer thickness may vary slightly).

S Re-index marked spider leg to another tower.

This can be done because spider has little effect

on overall clutch balance.

Re-indexing the spider 1/3 turn clockwise, or 1 leg, will

allow the realignment of the moveable and stationary

sheaves as previously marked. For example:

S .020s or .032s washer removed - re-index

spider clockwise 1/3 turn

S .050s or .064s washer removed - re-index

spider clockwise 1/3 turn

S Two .050s or .064s washers removed -

re-index clockwise 2/3 turn

NOTE: Alignment marks should be within 1s (25 mm) af-

ter final assembly and torquing.

PN 5132542

PN 5210754 .050s

PN 5210753 .030s

PN 5210752 .020s

PN 5132542 Stepped washer in addi-

tion to one of the above shims for pre-

cise shimming

Washers:

Enfocus Software - Customer Support

Loading...

Loading...