REAR SUSPENSION/TRACK/TRACTION

7.36

Stud Installation

1. Mark the stud pattern on the track.

2. Drill stud holes with a 1/4s (7mm) hollow-core drill bit. Make sure the drill is sharp for a clean hole.

3. Spin the non-cutting portion of the drill shank in the hole at high speed to melt the cords together, or melt them

with a 1/4-9/32s heated probe. This will prolong track life.

T-nut Studs

1. Push a T-nut tool through the hole from the outside of the track.

2. With the barrel end of the T-nut toward the track, spin a T-nut onto the tool. Pull the T-nut into the track until the

head is flush with the track.

3. Remove the tool and put a drop of Loctite¥ 262 or 271 on the nut threads and stud threads.

4. Secure the T-nut, slide a support washer onto the stud, and screw the stud into the T-nut

5. Torque to 80-100 in. lbs. and let dry for 24 hours at room temperature.

6. Check for loose studs after each event.

Push Through Studs

1. Push stud through track hole from inside track. Hand tighten domed support plate and Nyloc nut on the

exposed stud.

2. Tighten with a socket on the nut and a 5.32s allen wrench on the stud head. Tighten nut until the domed

washer bottoms out on the stud shoulder. If tightened beyond this point, the threads will be stripped.

3. Inspect for loose nuts after each event.

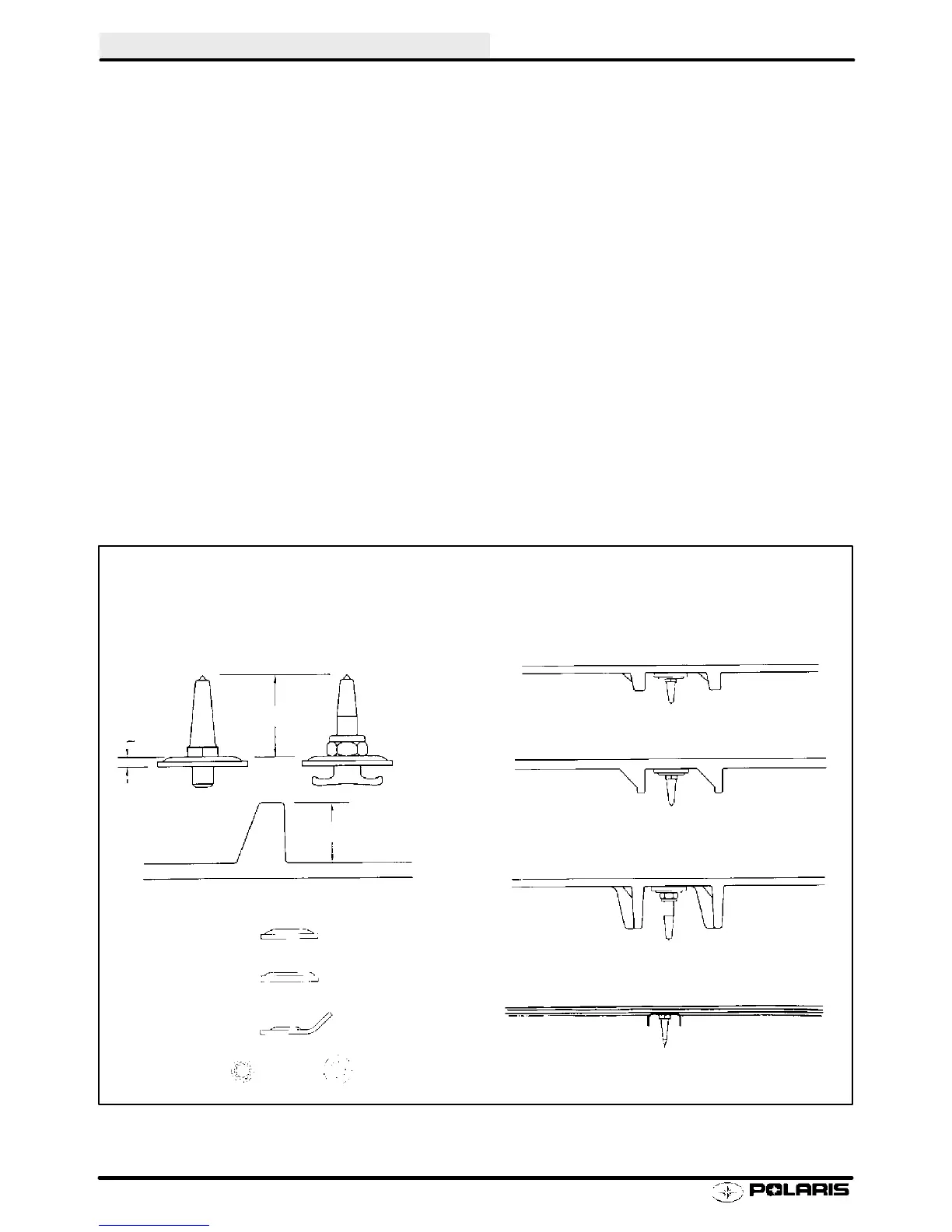

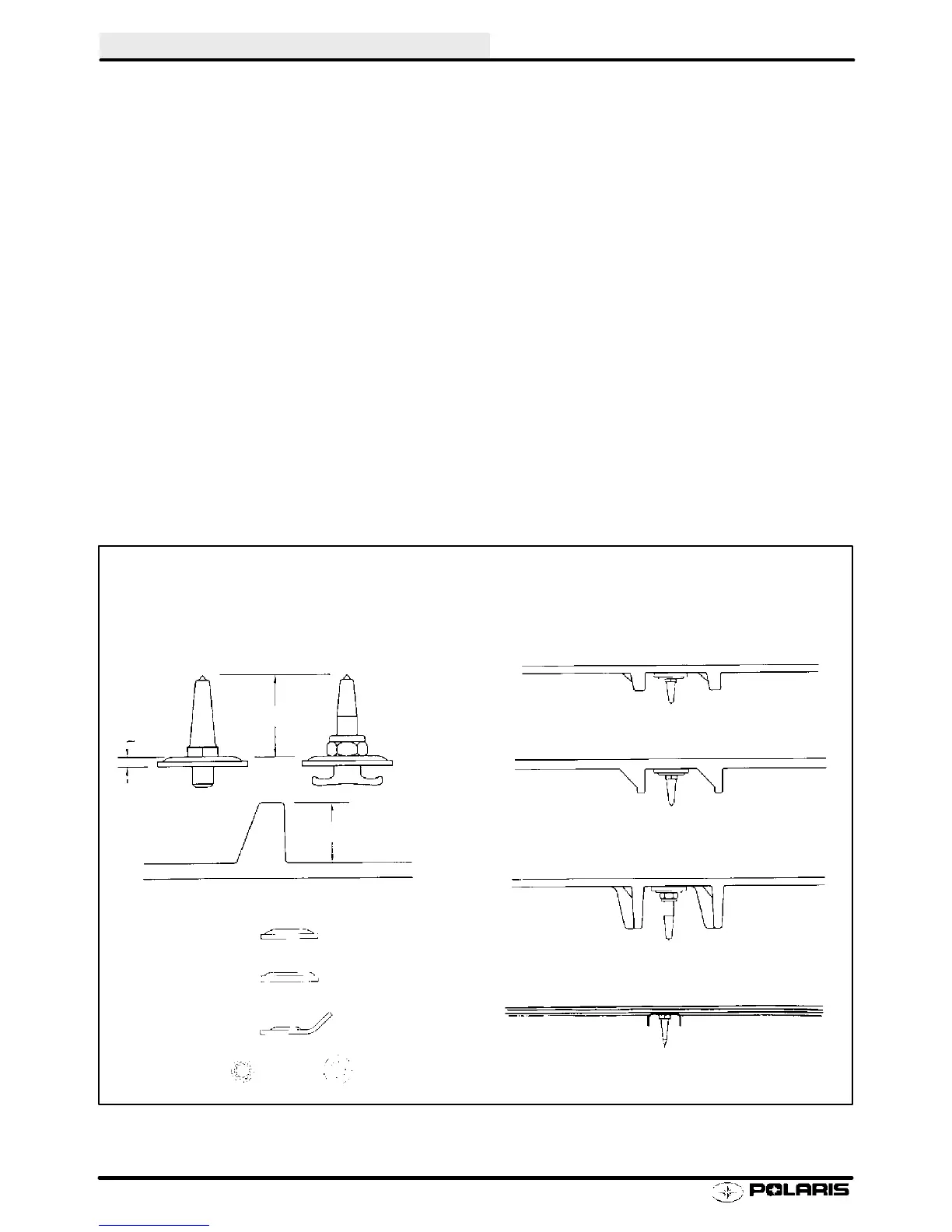

Refer to the diagrams below for stud length recommendations.

A

B

C

A = Stud Height

B = Washer Thickness

C = Track Lug Height

A + B - C = Penetration

Penetration

Steel .195

Aluminum .220

Backer Plates

Stud Mate .148

Hooker

Washer .025

Alum.

Shim .055

Stud Length

Maximum

Penetration

Maximum

Stud Length

Race

Type

Standard Low Profile Track

Deep Lug Track

1 1/4 to 1 1/2 Deep Lug Track

Steel Cleated Track

Oval

Drag

3/8s

3/4s

.750s

1.00s

Oval

Drag

3/8s

3/4s

.875s

1.00 - 2.00s

Oval

Drag

3/8s

3/4s

.700s

1.00s

Aggressive

1/4 - 3/8s

1.625s

Enfocus Software - Customer Support

Loading...

Loading...