4.16

FUEL INJECTION

Throttle Position Sensor Test

The throttle position sensor (TPS) is a non-serviceable item. If

it is faulty, it must be replaced. It can be tested using the

following method:

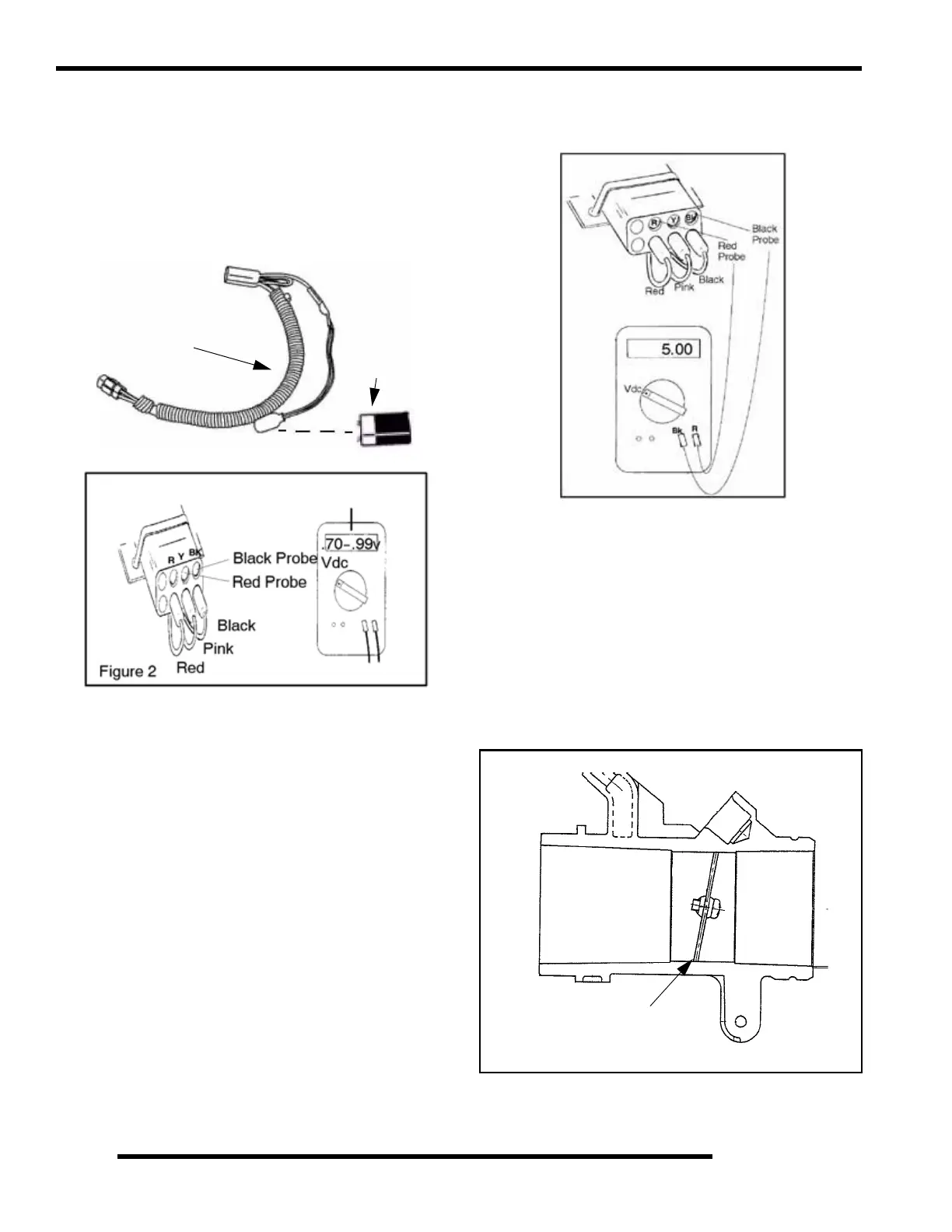

• Set up the TPS Test Adapter Harness (PU-47082),

according to the instructions. Make sure that the 9 volt

battery is new. Figure 2.

• With the test leads connected and the meter set, move

the throttle open and closed slowly while reading the

display. The voltage should increase smoothly with no

“jumps” or decreases when the throttle is applied.

• If the sensor does not function correctly, replace it.

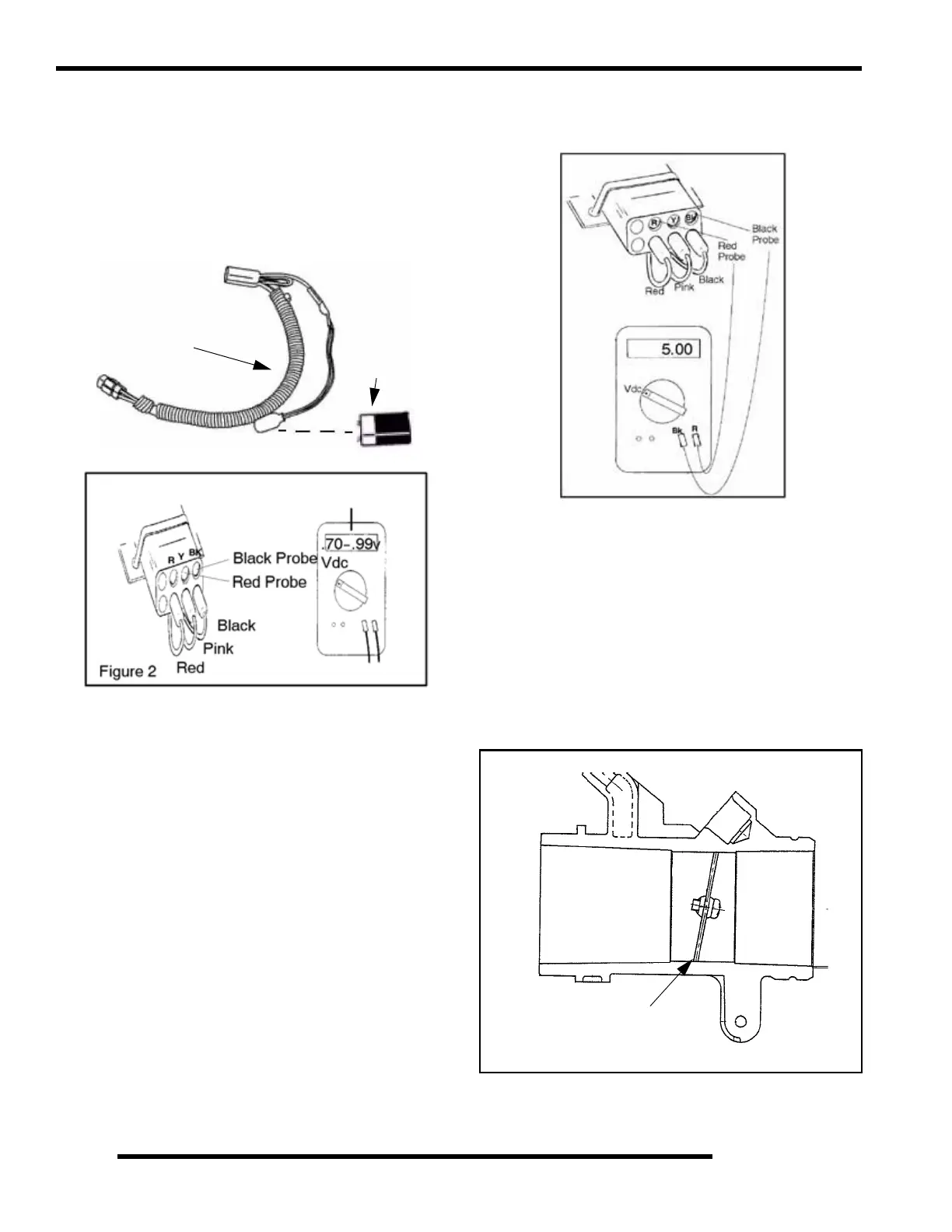

CORRECT REFERENCE VOLTAGE

A 5 volt reference voltage from the harness is required for the

TPS test to be accurate. Refer to the instructions provided with

the TPS Test Adapter Harness (PU-47082) or follow the steps

below to check reference voltage.

• Harness Test: Insert black voltmeter probe into the

“Bk” test port.

• Connect the red meter probe into the “R” port and

verify the voltage is 4.99-5.01 Vdc. If this reading is

low, verify the 9 volt battery is good or try a new 9 volt

battery.

Throttle Position Sensor Initialization

NOTE: The correct position of the TPS is

established and set at the factory. Use this

procedure only if the TPS was repositioned,

replaced or loosened.

STEP 1

Establishing zero offset voltage: This step is crucial as it sets

the TPS position using a fixed physical stop. This will insure

that the correct offset voltage is reached once the correct throttle

body flow is set.

PU-47082 TPS Test

Adapter Harness

Use NEW

9V battery

PU-47082 Harness

No “Jumps” in read out

Throttle Plate

Must Be Closed

Loading...

Loading...