10.33

ELECTRICAL

10

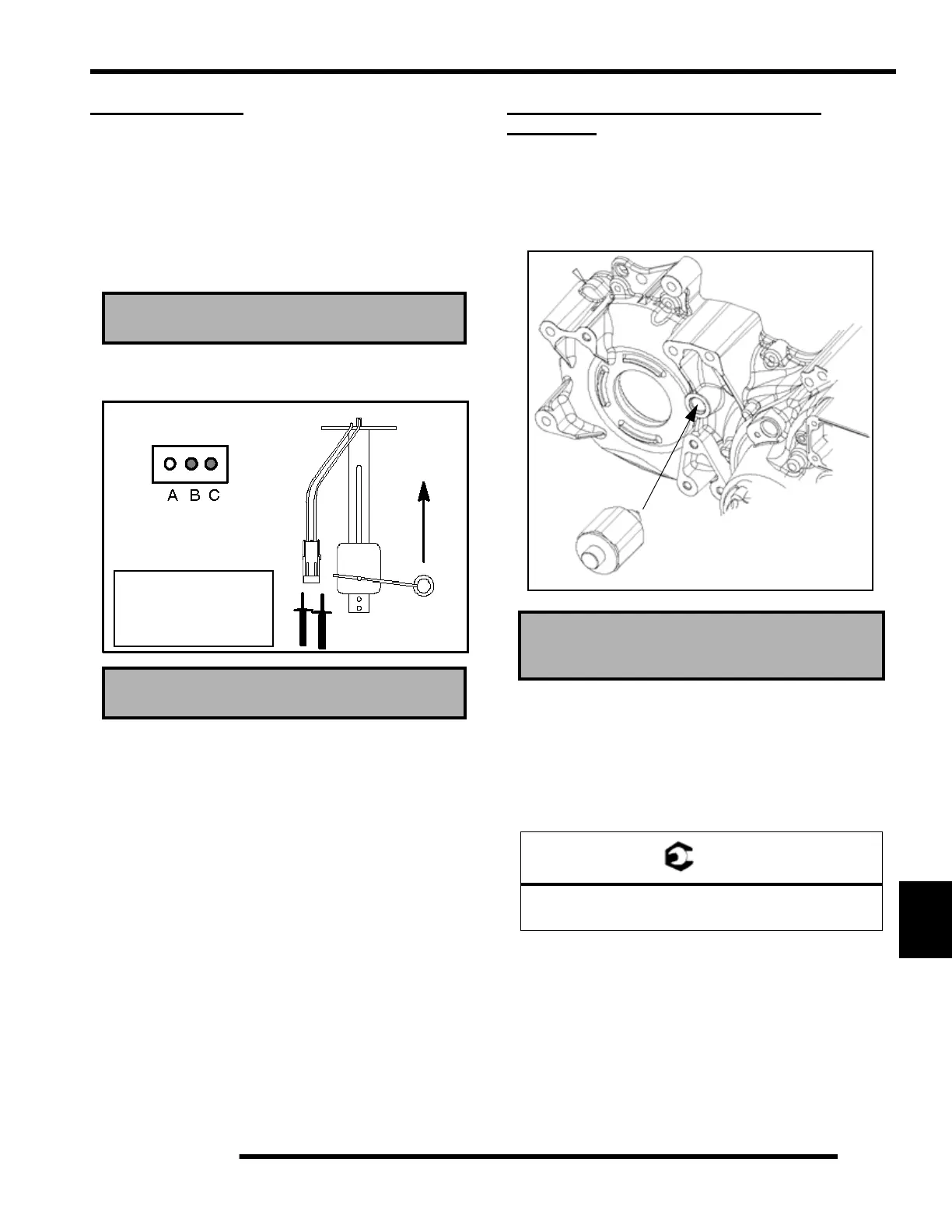

FUEL SENDER

Testing

1. Drain the fuel tank and remove it from the atv.

2. Set the fuel tank on a flat surface.

3. Hook up an ohm meter to the fuel sender harness Violet/

White wire (B) and Brown wire (C).

4. With the sender float in the empty position and compare

to specification.

5. Slowly tilt invert the tank so that gravity moves the sender

float to the full position and compare to specification.

6. If the readings are not to specification, or if the reading is

erratic or LCD display “sticks”, check the following before

replacing the fuel pump assembly.

• Loose float

• Float contact with tank

• Bent Float Rod

If none of the conditions exists, the sender assembly is faulty.

Fuel pump assembly replacement is required.

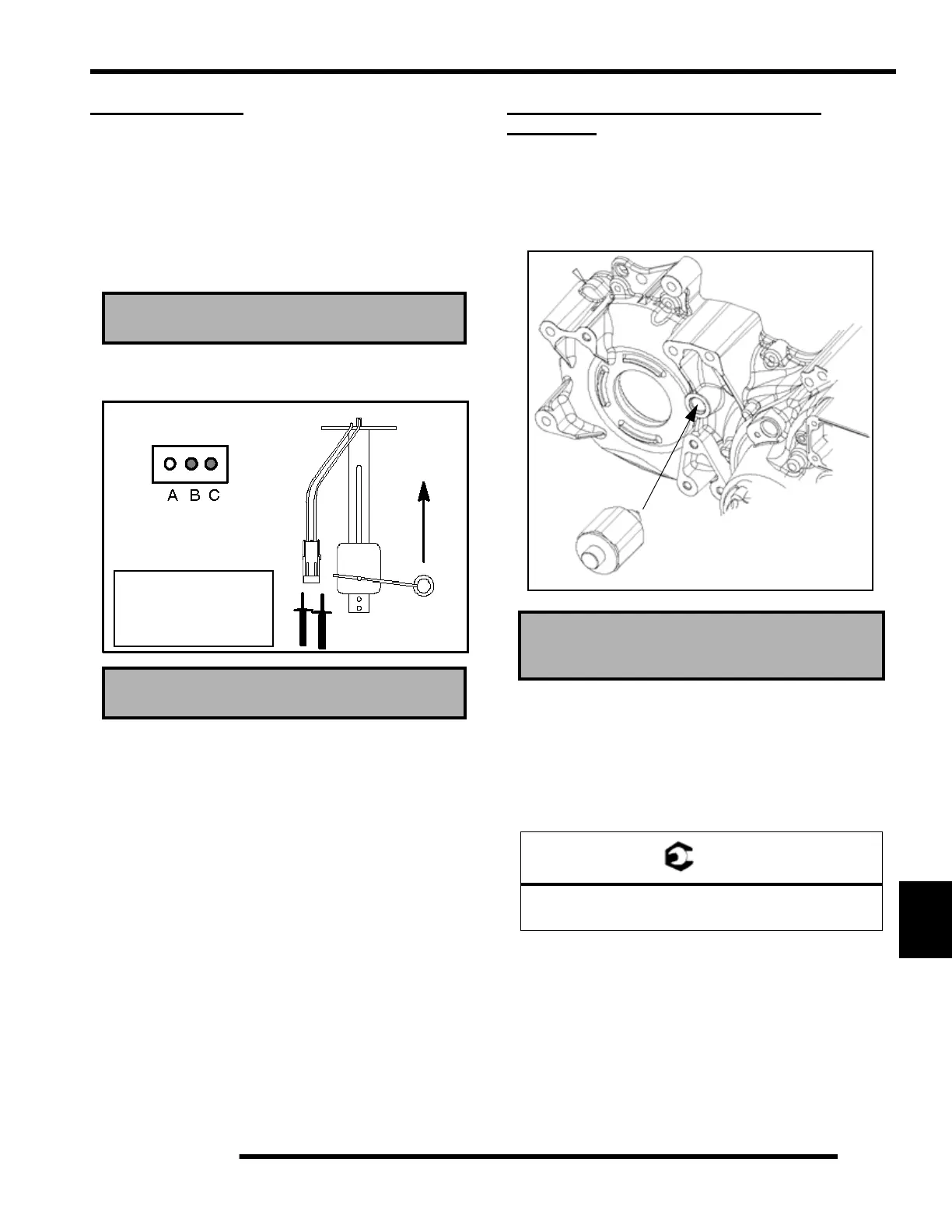

X2 / TOURING DIFFERENTIAL

SYSTEM

Solenoid Testing

Disconnect from the wire harness. Using a digital ohmmeter,

test the solenoid at the connector leads and compare to the

specification. Replacement of solenoid is required as it is not

serviceable.

Solenoid Replacement

1. Remove the solenoid using a suitable tool.

2. Coat threads of new solenoid with anti-seize compound or

sealant.

3. Thread new solenoid into gearcase housing. Tighten to

specification.

Fuel Sender - Empty: 5

Fuel Sender - Full:

Fuel Sender

Empty: 5

Half

Full

Differential Solenoid Resistance:

1.45 5 %

= T

Differential Solenoid Torque

23-27 ft. lbs. (31-37 Nm)

Loading...

Loading...