7.33

FINAL DRIVE

7

INSTALLATION

1. Slide shaft assembly into bearing carrier hub.

2. Apply anti-seize compound to splines of shaft.

3. Install a new lock ring and install the shaft.

4. Lift bearing carrier into place and install bolt to upper

control arm. Torque bolt to specification.

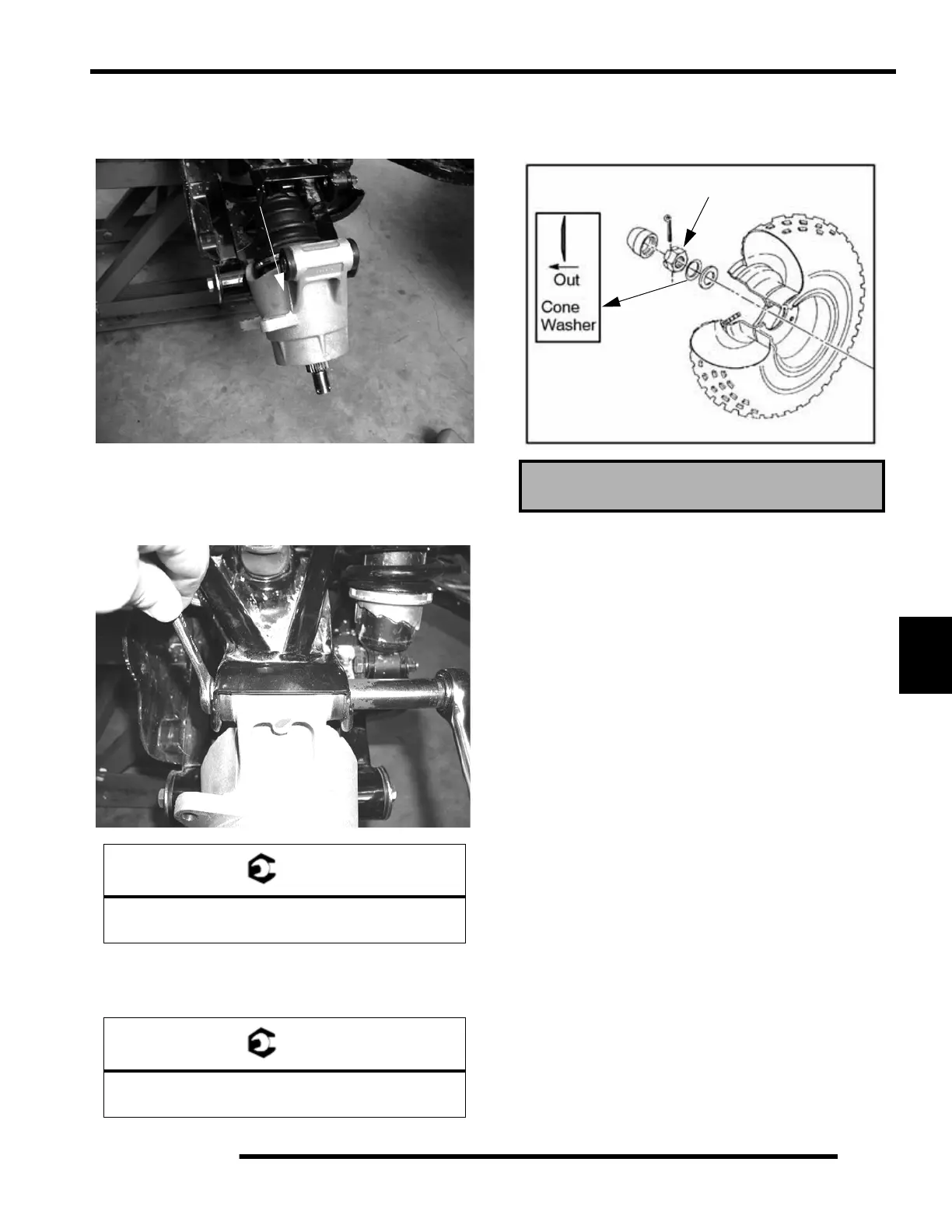

5. Install hub, flat washer, domed washer (domed side out)

and nut. Torque center hub nut to specification. Install new

cotter pin and hub cap.

6. Install brake caliper and tighten bolts to specification. Refer

to Chapter 9.

7. Install rear wheel and torque wheel nuts to specification.

8. Grease all fittings thoroughly with Premium U-Joint

Lubricant (PN 2871551).

Drive Shaft and CV Joint Handling Tips

Care should be exercised during driveshaft removal or when

servicing CV joints. Driveshaft components are precision parts.

Cleanliness and following these instructions is very important to

ensure proper shaft function and a normal service life.

• The complete driveshaft and joint should be handled by

getting hold of the interconnecting shaft to avoid

disassembly or potential damage to the driveshaft

joints.

• Over-angling of joints beyond their capacity could

result in boot or joint damage.

• Make sure surface-ground areas and splines of shaft are

protected during handling to avoid damage.

• Do not allow boots to come into contact with sharp

edges or hot engine and exhaust components.

• The driveshaft is not to be used as a lever arm to

position other suspension components.

• Never use a hammer or sharp tools to remove or to

install boot clamps.

• Be sure joints are thoroughly clean and that the proper

amount and type of grease is used to refill when joint

boots are replaced and when joints are cleaned. Refer

to text for grease capacity of CV joints and CV joint

boots.

= T

Upper Hub Carrier Bolt Torque:

37 ft. lbs. (50 Nm)

= T

Rear Hub Nut Torque:

80 ft. lbs. (109 Nm)

Refer to Page 7.2 for Wheel Nut Torque.

80 ft.lbs. (109 Nm)

Loading...

Loading...