3.20

ENGINE

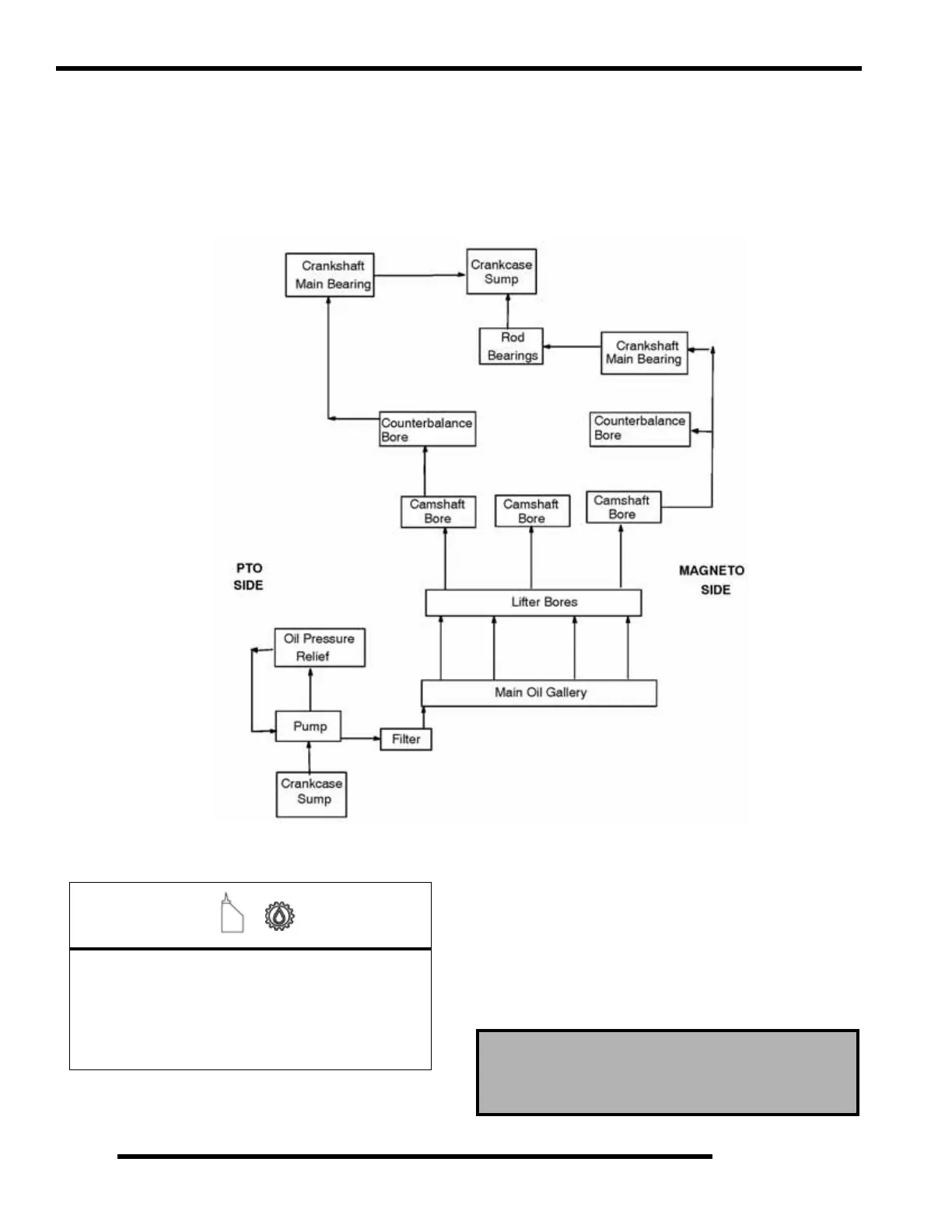

Oil Flow Chart

This chart describes the flow of oil through the 700/800 engine. Beginning in the crankcase sump, the oil is drawn through an oil

galley to the feed side of the oil pump. The oil is then pumped through the oil filter. If the oil filter is obstructed, a bypass valve

contained in the filter allows oil to bypass the filter element. At this point, the oil is supplied to the main oil galley through a crankcase

passage. Oil is then diverted three ways from the main oil galley, with the first path entering the camshaft bores, onto the rear balance

shaft journal and then draining back into the crankcase sump. The second oil path from the main oil galley feeds the lifter bores and

then drains back to the crankcase sump. The third oil path flows through a crankcase galley to the MAG side crankshaft journal and

also to the front balance shaft journal and onto the crankcase sump. The oil pressure switch is fed off the main oil galley.

Engine Lubrication Specifications OIL PRESSURE TEST

1. Remove blind plug/sender from left side of crankcase.

2. Insert a 1/8 NPT oil pressure gauge adaptor into the

crankcase and attach the gauge.

3. Start engine and allow it to reach operating temperature,

monitoring gauge indicator.

NOTE: Use only Polaris PS4 Plus 2W/50 Synthetic

Engine Lubricant.

=

Capacity - Approximately 2 U.S. Quarts (1.9 l)

Oil Type - Polaris PS4 Plus 2W/50 Synthetic

Filter Wrench - PV-43527 or equivalent

- Oil Pressure Specification -

35-39 PSI @ 5500 RPM, Polaris 2W/50 Synthetic ,

Engine at operating temperature.

Oil Pressure at 5500 RPM (Engine Hot):

Standard: 39 PSI

Minimum: 35 PSI

Loading...

Loading...