3.43

ENGINE

3

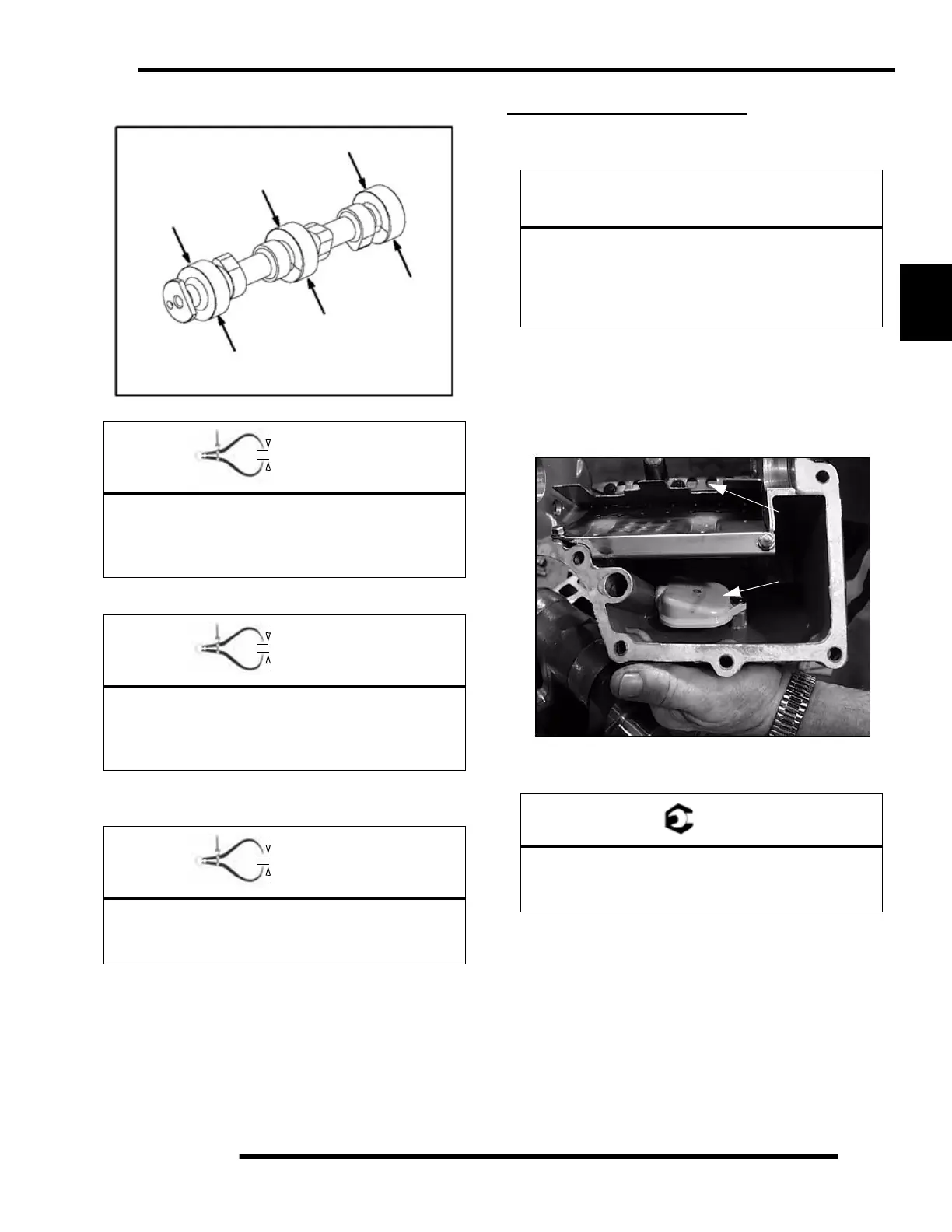

4. Measure camshaft journal outside diameters (O.D.).

5. Measure ID of camshaft journal bores.

6. Calculate oil clearance by subtracting journal O.D.'s from

journal bore I.D.'s. Compare to specification.

NOTE: Replace camshaft if damaged or if any part is

worn past the service limit.

NOTE: Replace engine block if camshaft journal

bores are damaged or worn excessively.

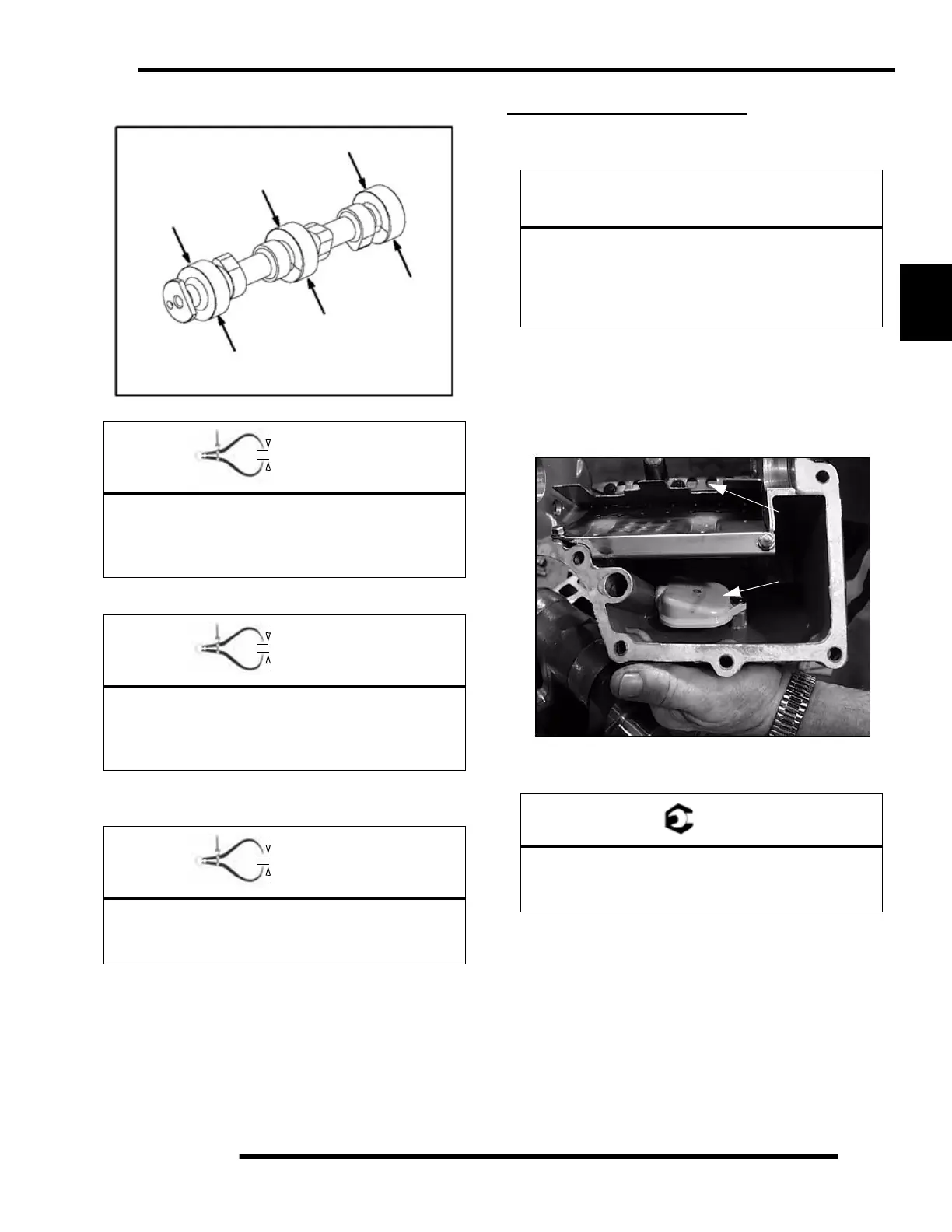

ENGINE REASSEMBLY

CRANKCASE REASSEMBLY

NOTE: Before assembly, clean the bolts and bolt

holes with Primer N (PN 2870585) to remove any

debris. This will ensure proper sealing when

installing bolts.

1. Install oil pick up (A), if removed. Torque to specification.

2. Install oil baffle weldment (B). Torque bolts to

specification.

3. Install the balance shaft. Inspect balance shaft clearance

(C) in both gearcase halves. Rotate balance shaft to ensure

that there is clearance between it and oil baffle weldment.

= In. / mm.

Camshaft Journal O.D. :

A. (Mag): 1.654" ± .00039" (42 ± .010 mm)

B. (Ctr.): 1.634" ± .00039" (41.50 ± .010 mm)

C. (PTO): 1.614" ± .00039" (41 ± .010 mm)

= In. / mm.

Camshaft Journal Bore I.D.:

(Mag): 1.656" ± 0.00039" (42.07± 0.010 mm)

(Ctr.) 1.637" ± 0.00039" (41.58 ± 0.010 mm)

(PTO) 1.617" ± 0.00039" (41.07 ± 0.010 mm)

= In. / mm.

Calculated Camshaft Oil Clearance:

Std: 0.0027" (.070mm)

Limit: .0039" (.10 mm)

A

B

C

CAUTION

After any reassembly or rebuild, the engine must be

primed using the Oil Priming Adapter (PU-45778)

and a 3/4-full oil filter before initial start-up. Follow

Steps 45-46 of this section to prime the engine and

to help aid proper break-in.

= T

Oil Baffle Weldment &

Oil Pick Up Bolt Torque:

60 ± 6 in. lbs. (6.8 ± 0.68 Nm)

A

B

Loading...

Loading...