Shaft, Splined

213

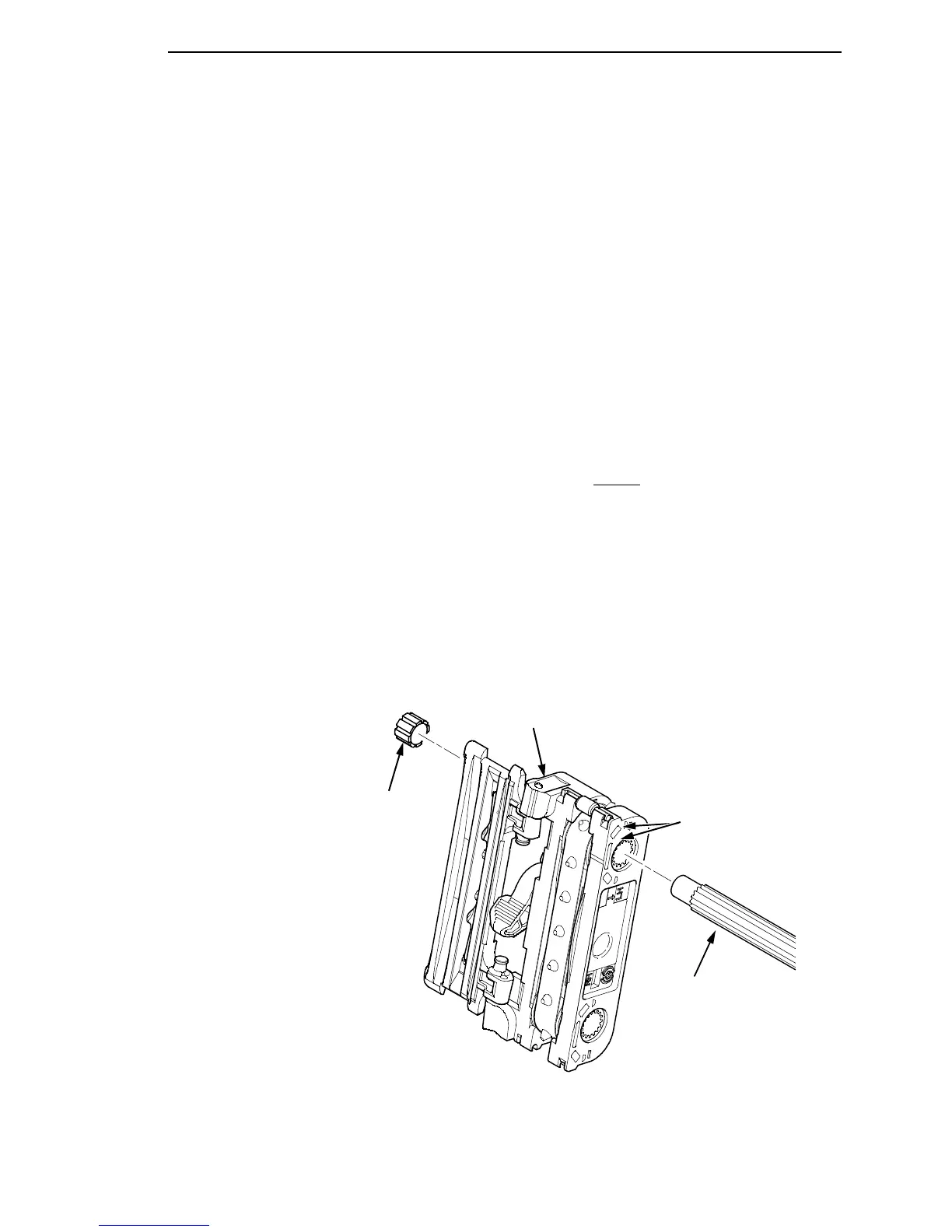

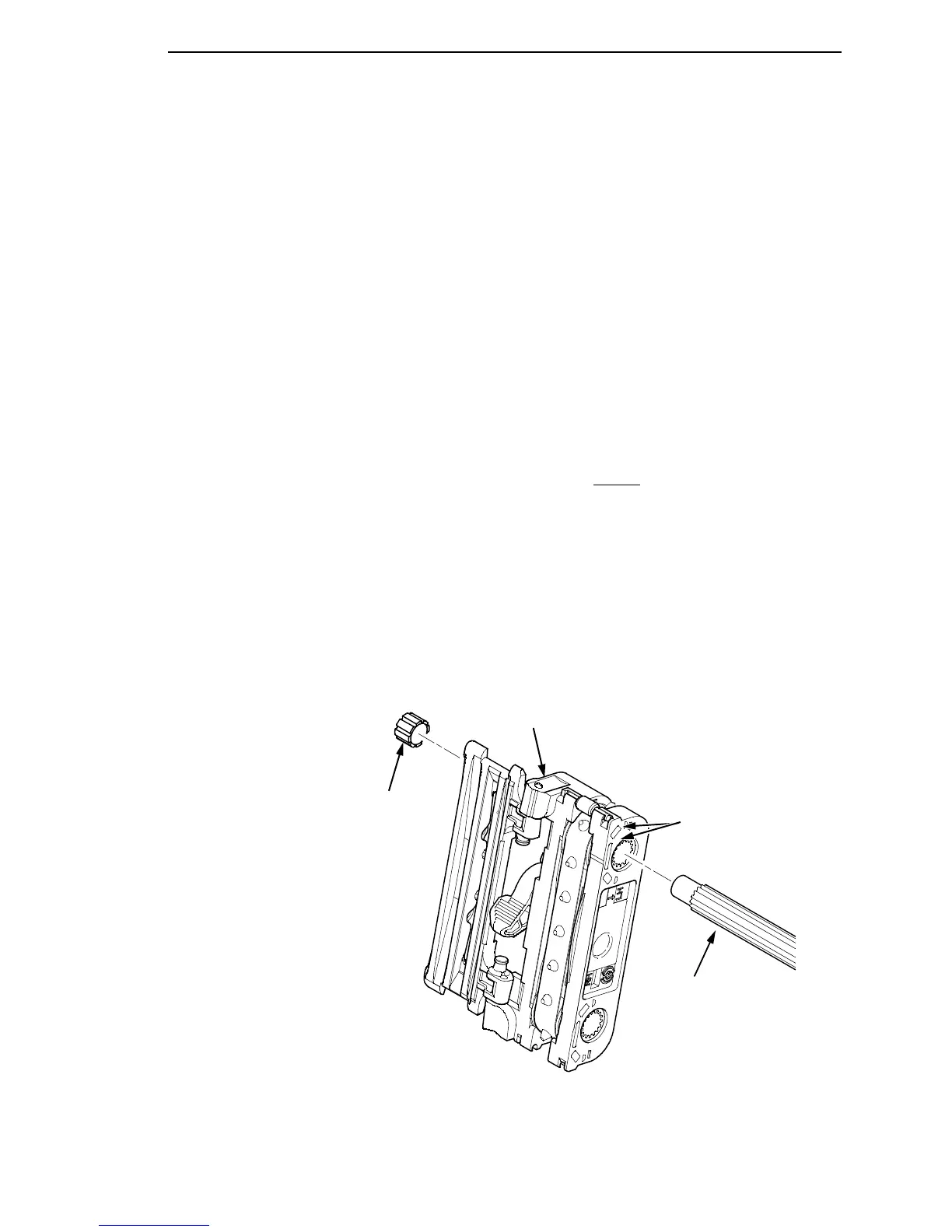

Installation

1. Open the doors on the left and right tractors. Position the tractor belts so

the alignment marks are at the top on both tractors. (See Figure 31.)

2. Slide the splined shaft through the right side plate and tractors. Make sure

the same spline passes the marked groove on each tractor. (See Figure

31.)

3. Install the tolerance ring on the left end of the splined shaft (page 240,

item 5).

4. Insert the tolerance ring lead-in portion into the sealed ball bearing in the

left tractor shaft plate (page 240, items 3, 5, and 6) while sliding the ball

bearing into the right side plate. Push the splined shaft to the left until the

flange on the ball bearing is in solid contact with right side plate. The

splined shaft will protrude about 1/16 inch from the ball bearing.

5. Install the right tractor shaft plate and screw (page 240, items 7 and 8) by

first sliding the upper “fingers” up and against the flange on the ball

bearing, then sliding the rectangular cutout over the support shaft end,

then snapping the U-shaped “spring” behind

the tab on the right side

plate.

6. Install the paper feed timing belt (page 168).

7. Set the paper feed timing belt tension (page 134).

8. Install the paper supports on the splined and support shafts. (See page

240, item 4.)

9. Insert the lower ends of the paper supports into the groove in the upper

forward edge of the platen.

10. Return the printer to normal operation (page 133).

Figure 31. Splined Shaft and Tractor Installation

Splined Shaft

NOTE: Align the marks on

both tractors before inserting

the splined shaft.

Tractor

Alignment Marks

Tolerance Ring

Loading...

Loading...