5.7. Auto-Configuration Procedure

The direction of flow of the conveyor dictates how to begin the Auto-Configuration procedure. The Module

located at the most upstream or in-feed end of the conveyor is defined as the Auto-Configuration Node. The

Auto-Configuration procedure is initiated from the Auto-Configuration Node. Because of its physical location

on the conveyor path and physical location in the Ethernet connection chain; the Auto-Configuration Node

will automatically connect to all downstream modules and set their I.P. address for communication.

Before You Begin

• All sensors should be clear. Auto-Configuration assumes that state of the sensor is the “zone empty”

state

• Make sure you have no more than 221 Ai2 Modules connected. Auto-Configuration will not configure

past 221 Ai2 Modules in one network

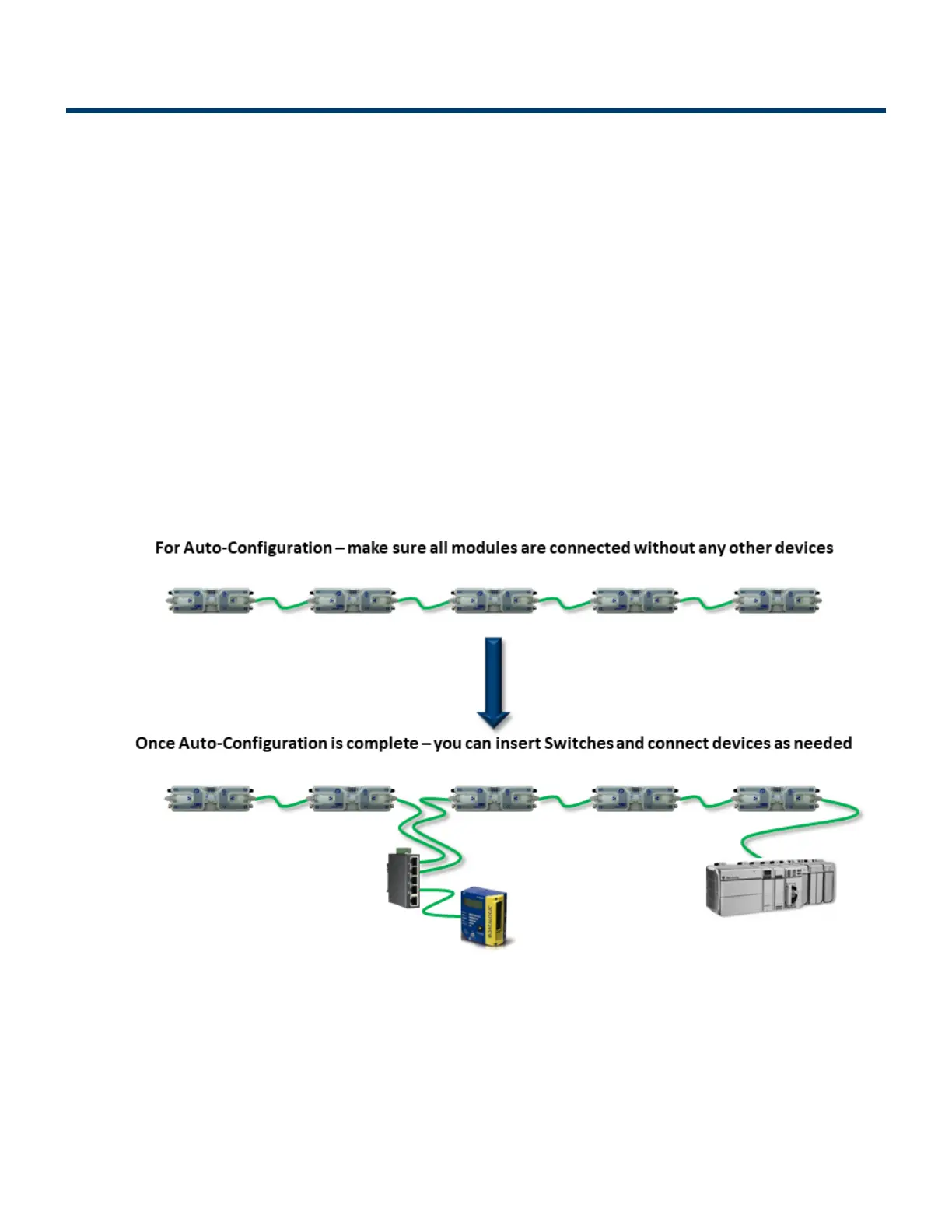

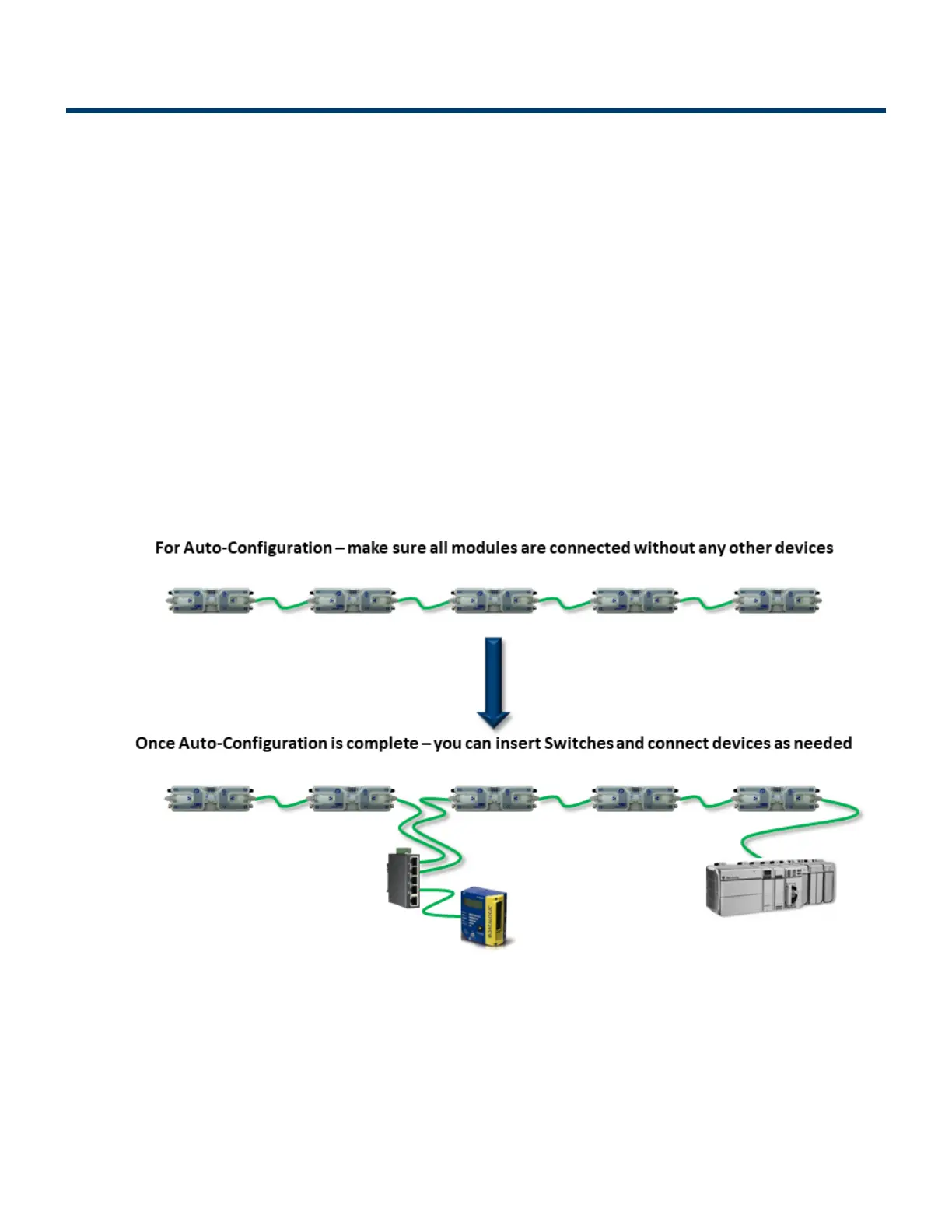

• Make sure that there are no other Ethernet devices or switches connected in your string of Ai2

Modules. After Auto-Configuration is complete and successful, you can interrupt the Ethernet string

with other devices and/or switches

The direction of flow of the conveyor dictates where to begin the Auto-Configuration Procedure. The Ai2

Module located at the most upstream or in-feed end of the conveyor is the module where the procedure

must be initiated.. Because of its physical location on the conveyor path and physical location in the

Ethernet connection chain; the most upstream Ai2 Module will automatically connect to all downstream Ai2

Modules and set their I.P. address for communication. Then the routine automatically sets the direction of

flow.

PULSEROLLER ConveyLinx-Ai2 User's Guide - 1.7

Page 46 of 154

Loading...

Loading...