5.8. Expected Results

When the Auto-Configuration Procedure routine is complete, each Ai2 Module will automatically reboot.

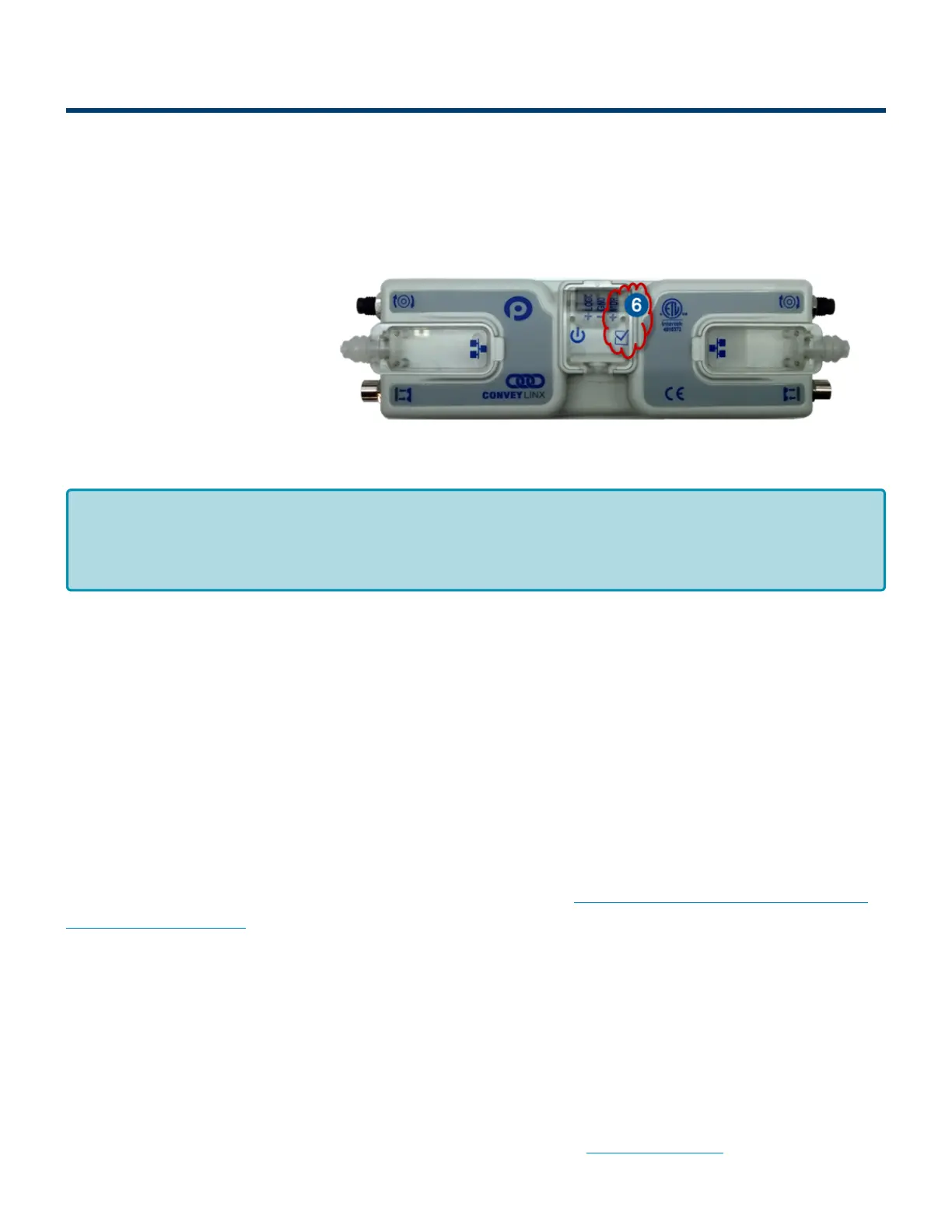

When a Ai2 Module has been successfully configured and rebooted, its Module Status LED will blink on

and off green.

When the module has been

properly configured and is

operational, its Module

Status LED will blink on and

off Green

How to verify success

Conveyor Operation

Place a carton on your empty conveyor so that it blocks the most upstream zone’s sensor. It should convey

all the way to the discharge end and the last most downstream zone should try to convey it off the end of its

zone. If this does not happen, then at the point where the carton stops, check that module’s motor

connection is sound and that the zone’s sensor is properly aligned. If the sensor was not properly plugged in

and powered when the Auto-Configuration Procedure was performed, you will have to perform the

procedure again. If the sensor was powered but is misaligned when the Auto-Configuration Procedure

was performed, you can either perform the procedure again or use EasyRoll to change the logical polarity

of that particular sensor.

Examine the Network

While the Auto-Configuration Procedure is in process, you should see all of your modules’ LEDs flashing

on and off red. If this is not the case, then check your Ethernet cables and connections and power

connections.

To verify that all the modules you expected to be configured are in fact configured, with EasyRoll you can

connect to your newly configured Ai2 Module network and perform a Discover function. The Discover

Please note that the time to complete the Auto-Configuration Procedure is dependent on

the number of Ai2 Modules being configured. Larger networks will take more time than

smaller networks

*

PULSEROLLER ConveyLinx-Ai2 User's Guide - 1.7

Page 52 of 154

Loading...

Loading...