6.4. Automatic Module Replacement

Once a linear conveyor has been commissioned by Auto-Configuration Procedure, the Ai2 Module store

configuration data about its upstream and downstream neighboring modules. This configuration data is

automatically updated even if the linear conveyor has had its parameters modified by the EasyRoll software.

The Ai2 Module firmware uses this feature to allow for easy module replacement so that the entire linear

conveyor does not have to be Auto-Configured again in order to replace a single Ai2 Module.

Module Replacement Using EasyRoll

1. Disconnect existing module’s motor(s), network, photo-sensor(s), and power connections. The order of

disconnection does not matter.

2. Connect new module’s motor(s), sensor(s), network connections and power connections.

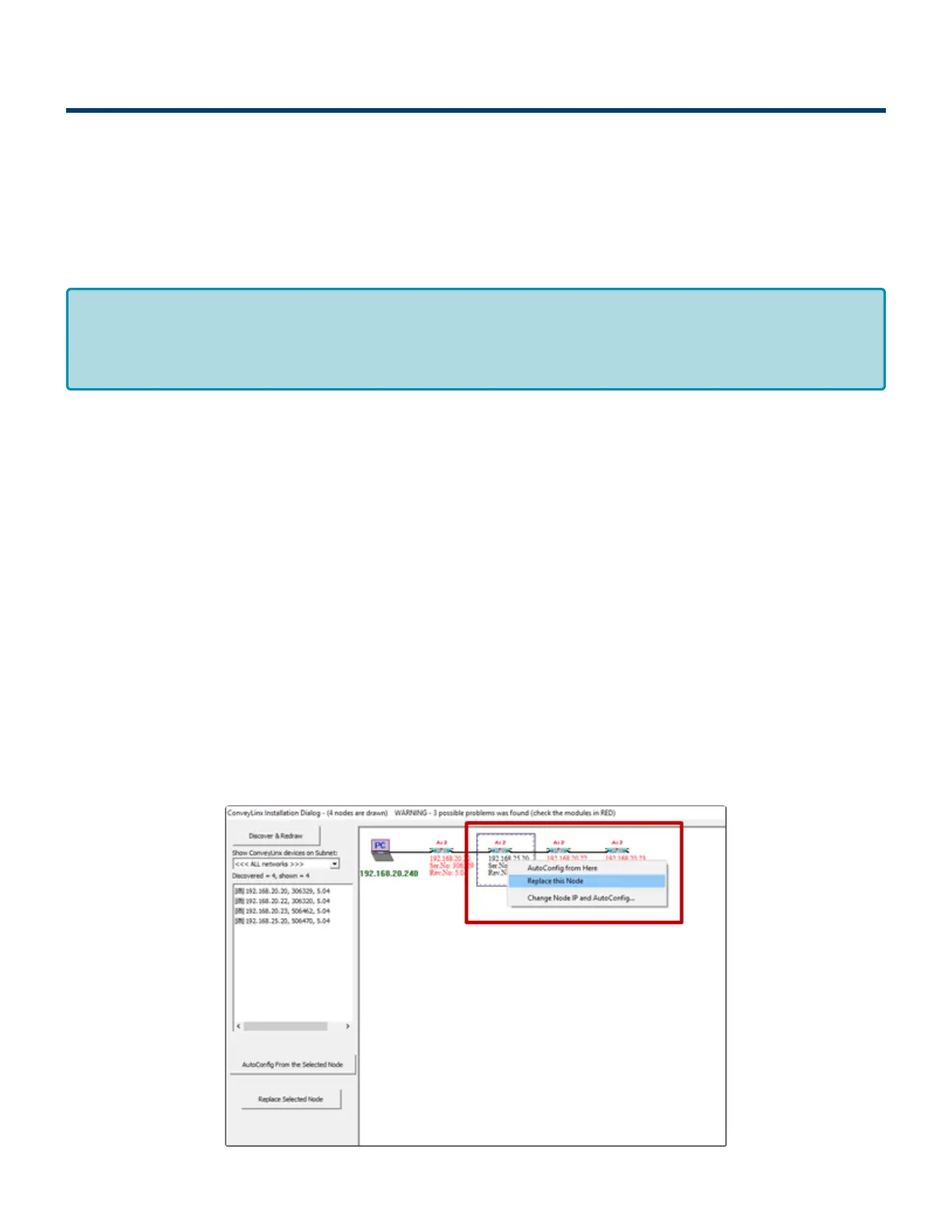

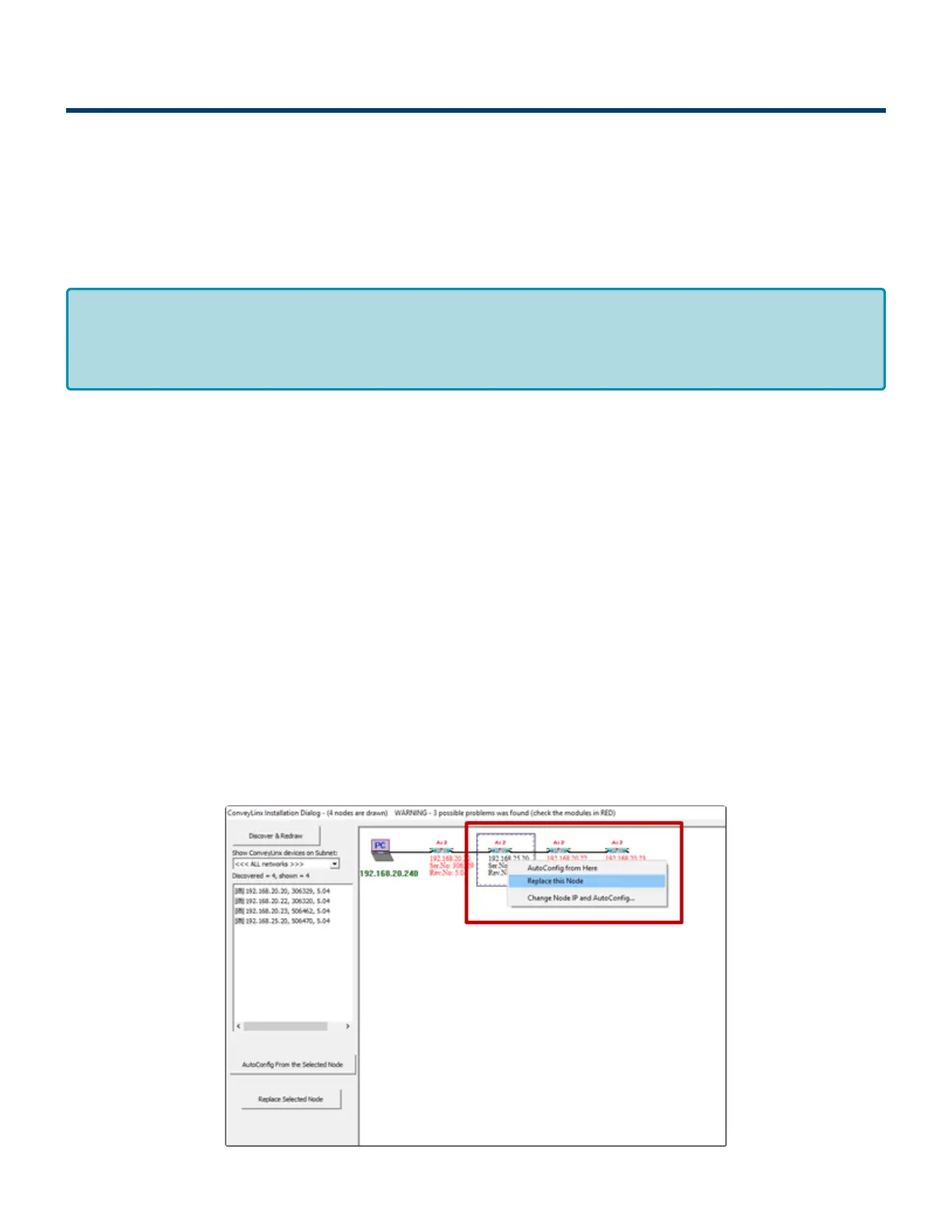

3. Start EasyRoll V4.04 or higher. Invoke the Advanced Dialog and go to the Network Services tab, click on

the Discover button. All modules in the network should be display. Click on AutoConfig button and after a

few seconds the topology of the ConveyLinx modules will be displayed.

4. Click on the module in the Tree View you want to add as the replacement module

5. Right-Click and select Replace this Node from the menu to begin the replacement process as shown in

Figure 35. Note that you can also select the node from the list of modules on the left-hand side and then

click the Replace Selected Node button.

6. Wait until Module performs its internal boot-up procedures which will be indicated when the Module

Status LED blinks on and off green.

Automatic Module Replacement procedure will work to replace a module on systems with

multiple subnets. You do not have to temporarily disconnect any network connections or

otherwise isolate the subnet where the replacement procedure needs to occur

*

PULSEROLLER ConveyLinx-Ai2 User's Guide - 1.7

Page 64 of 154

Loading...

Loading...