46

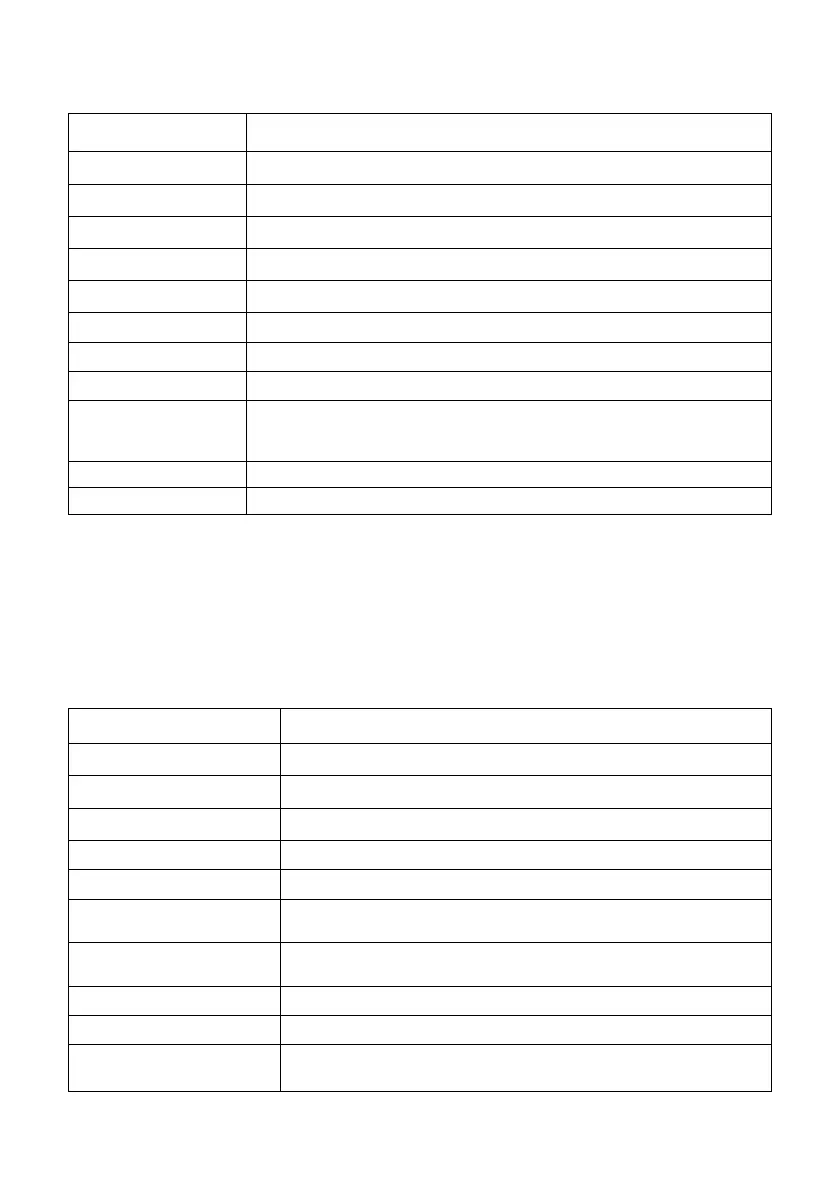

Variables description

Variable Description

Project Project name (31 characters maximum).

Adjustment type Performed adjustment type.

Operator Logged-in operator name.

Project Project name printout.

Date Adjustment performance date.

Time Adjustment performance time.

Scale S/N Serial number of the scale.

Platform number Number of platform via which the adjustment was carried out.

Adjustment result

difference

Difference between mass of the adjustment weight that was measured

during the last adjustment and mass of a currently measured

adjustment weight.

Dashes Dashed line separating printout data and signature fields.

Signature An area for the signature of an operator carrying out the adjustment.

17.4. Dosing Report

Group of parameters allowing you to declare variables that are to be printed on

a dosing report printout. Dosing report is generated automatically after either

completion or abortion of each process.

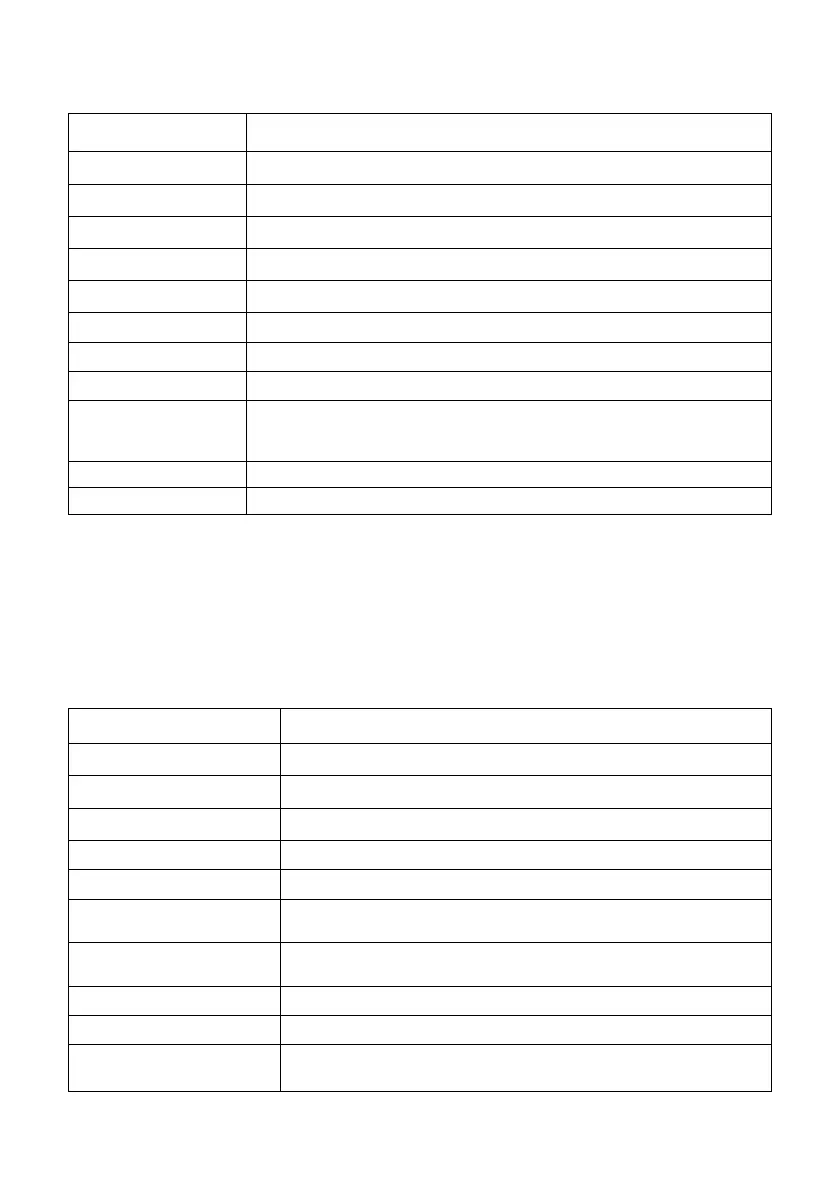

Variables description

Variable Description

Start date Dosing process start date.

End date Dosing process end date.

Operator Operator carrying out the dosing process.

Customer Customer for whom the dosing process is carried out.

Product Name of dispensed product selected from <Products> database.

Fast dosing threshold

[DT1]

Mass value for rough dosing in case of automatic 2-stage

dispensing.

Dosing threshold [DT2]

Target mass value to be dosed in case of an automatic

dispensing.

Dosing correction Dosing correction value.

Dosing mass Net value of mass that is to be dosed, given in an adjustment unit.

Difference

Difference between the net value of mass that is to be dosed and

a value of automatic dosing threshold.

Loading...

Loading...