Effectivity: 914 Series

Edition 2 / Rev. 0

d04276

page 35

July 01/2008

BRP-Rotax

INSTALLATION MANUAL

10.2) Permissible fitting positions

See Fig. 9/10/11.

To simplify the matter, reference is made only to the 2 engine attachment points R1,

L1 and the 2 turbo charger attachment points R(T)2 and L(T)2.

Location of the 2 turbo charger attachment points R(T)2 und L(T)2.

◆ NOTE: All dimensions to point of reference (P) and the system of coordi-

nates remain unchanged.

The following details of engine position are with reference to aircraft on ground,

ready for take off.

- engine suitable for propeller in tractor or pusher arrangement,

- propeller shaft above cylinders. See Fig. 2.

▲ WARNING: For upside down installation of the engine, the lubrication system,

fuel system and the cooling system are unsuitable!

Longitudinal axis:

- The centre of the attachment points L1 and L(T)2 must be on axis x2 parallel to

the x axis.

Allowable pitch deviation of parallelism of axes:

max. 6° counter-clockwise, on ground

max. 10° counter-clockwise, in operation

max. 30° clockwise (See Fig. 9)

▲ WARNING: On installations with fuel tank located above carburetor level com-

bined with badly closing carb float valve, fuel could pass into cylinders

at more than 6° decline of propeller shaft axis after longer periods of

downtime. See FAR, § 33.17.

▲ WARNING: Tighten all engine suspension screws as specified by the aircraft

manufacturer.

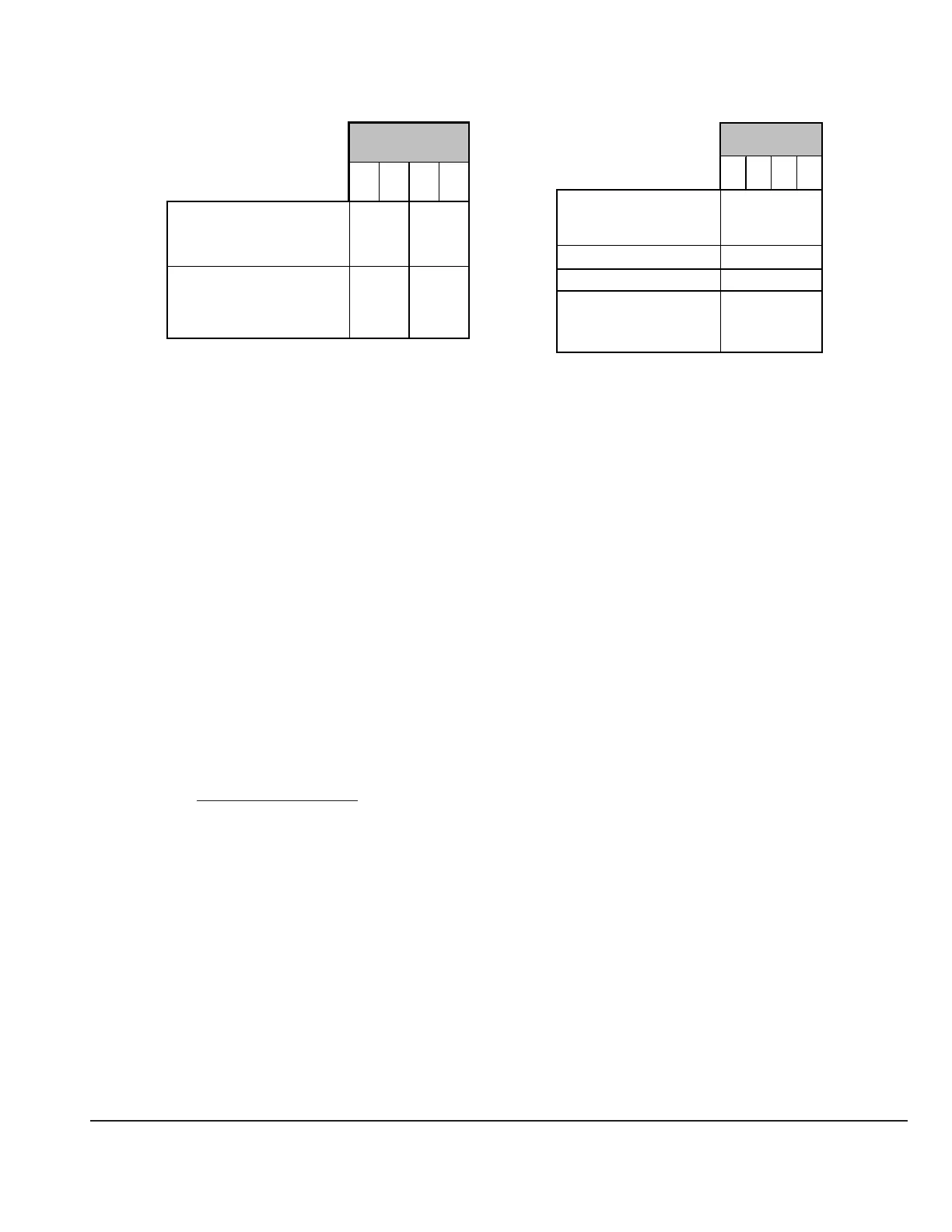

04862

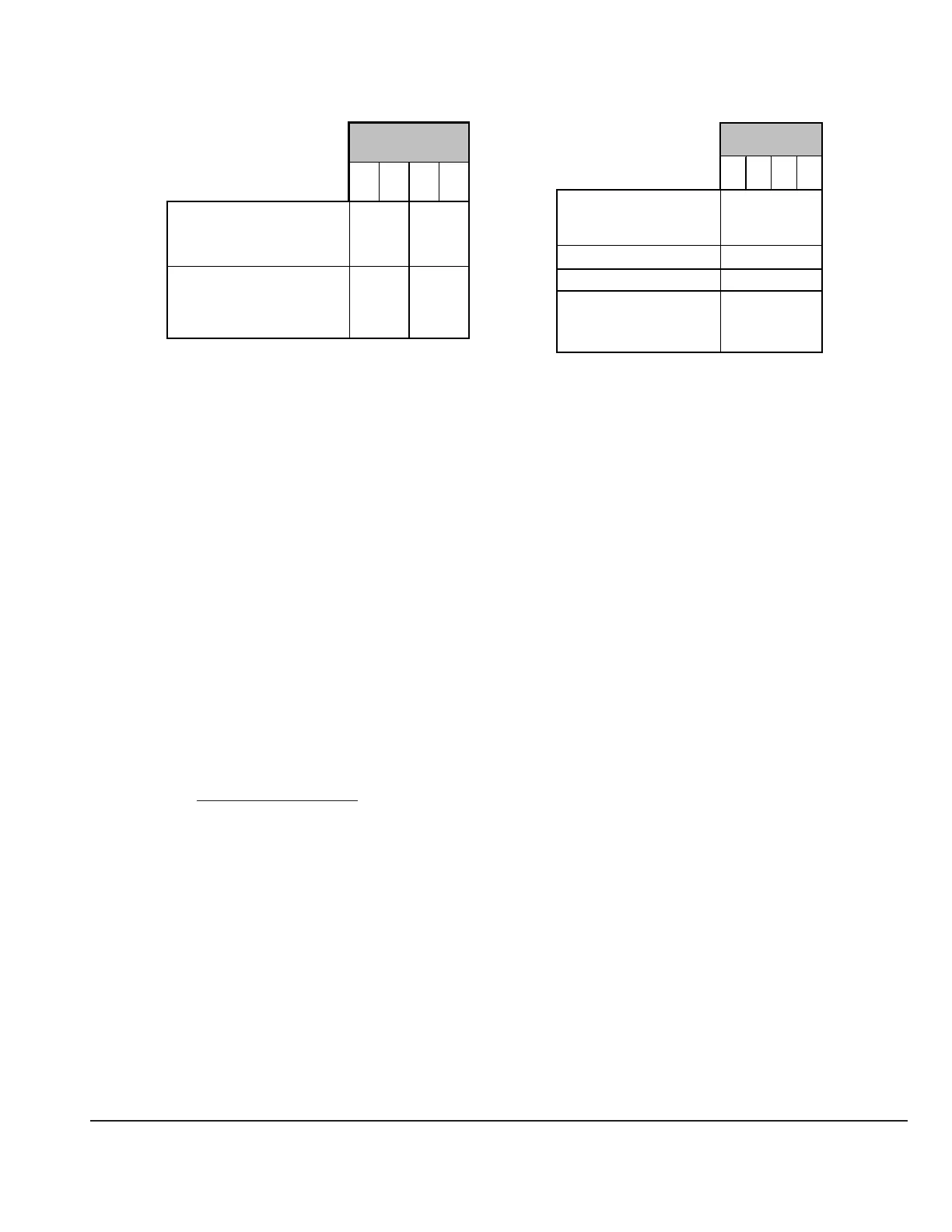

04861

attachment point

L1 R1 L4 R4

max. allowable forces

(limit load) in (N) in x, y

and z axis

5000 1900

max. allowable bending

moment (limit load) in

(Nm) in x, y and z axis

77 39

attachment point

L2 R2 L3 R3

max. allowable forces

(limit load) in (N)

in x axis

5 000

in y axis 2 000

in z axis 3 000

max. allowable bending

moment (limit load) in (Nm)

in x, y and z axis

100

Loading...

Loading...