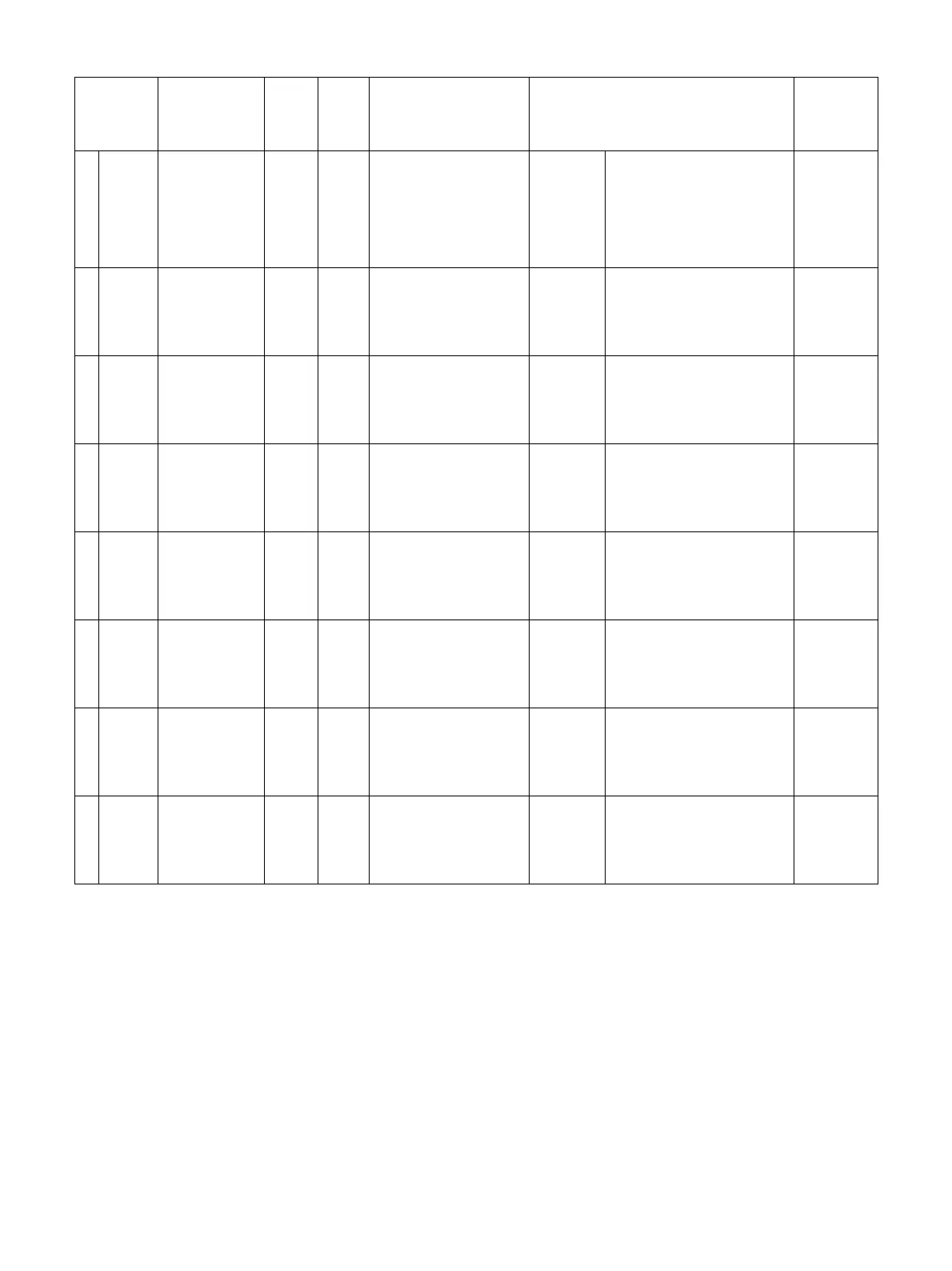

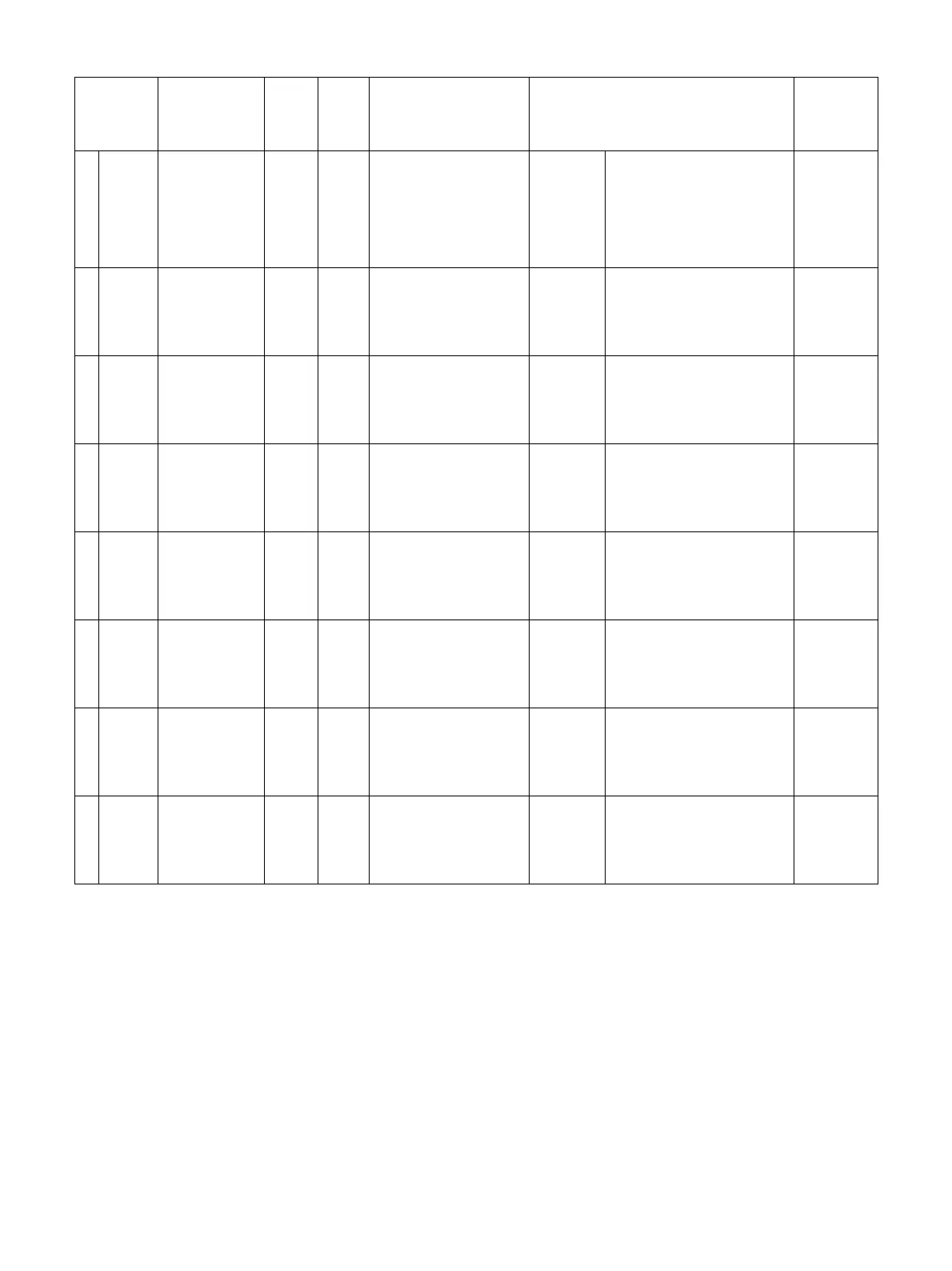

MX-3114N SIMULATION 6 – 11

Inner finisher (MX-FN17)

Item/Display Content

Setting

range

Default

value

Purpose (Case where the

adjustment is required)

Change when the adjustment value is

increased or decreased

Change

when the

adjustment

value is

changed by 1

A FRONT

ADJUST

Alignment position

adjustment

(F side alignment

plate stop position)

(Paper alignment

adjustment)

2 - 18 10 This adjustment is used to

adjust the paper alignment

width when the paper

alignment is improper.

Alignment is determined by

the combination of the both

adjustment values of FRONT

ADJUST and REAR ADJUST.

F side paper

alignment

stop position

(F/R

direction)

When the adjustment value is

increased, the alignment plate stop

position is shifted to the R side.

When the adjustment value is

decreased, the alignment plate stop

position is shifted to the F side.

0.3665mm

B REAR

ADJUST

Alignment position

adjustment

(R side alignment

plate stop position)

(Paper alignment

adjustment)

2 - 18 10 When changing the

adjustment values of FRONT

ADJUST and REAR ADJUST

from the default values, be

sure to change them by the

same variation.

R side paper

alignment

stop position

(F/R

direction)

When the adjustment value is

increased, the alignment plate stop

position is shifted to the F side.

When the adjustment value is

decreased, the alignment plate stop

position is shifted to the R side.

0.3665mm

C STAPLE

REAR

Stapling position

adjustment (one

position at the

rear)

68 - 132 100 When the staple position on

the R side is shifted, perform

the adjustment.

Staple

position

(Stapler stop

position)

(F/R

direction)

When the adjustment value is

increased, the staple position is

shifted to the rear side.

When the adjustment value is

decreased, the staple position is

shifted to the front side.

0.155mm

D STAPLE

FRONT

Stapling position

adjustment (one

position in front)

68 - 132 100 When the staple position on

the F side is shifted, perform

the adjustment.

Staple

position

(Stapler stop

position)

(F/R

direction)

When the adjustment value is

increased, the staple position is

shifted to the rear side.

When the adjustment value is

decreased, the staple position is

shifted to the front side.

0.155mm

E STAPLE

BOTH

Stapling position

adjustment (center

position of two

positions binding)

68 - 132 100 When the staple off-center is

shifted, perform the

adjustment.

Staple

position

(Stapler stop

position)

(F/R

direction)

When the adjustment value is

increased, the staple position is

shifted to the rear side.

When the adjustment value is

decreased, the staple position is

shifted to the front side.

0.155mm

F STAPLE

PITCH

Stapling position

adjustment (staple

pitch of two

positions binding)

68 - 132 100 When it is required to change

the staple interval, perform

the adjustment.

Staple

position

(Stapler stop

position)

(F/R

direction)

When the adjustment value is

increased, the staple interval is

increased.

When the adjustment value is

decreased, the staple interval is

decreased.

0.155mm

G PUNCH

CENTER

Punch center

positioning sensor

37 - 63 50 When the punch off-center is

shifted, perform the

adjustment.

Punch

position

(F/R

direction)

When the adjustment value is

decreased, the punch position is

shifted to the front side.

When the adjustment value is

increased, the punch position is

shifted to the rear side.

0.1441mm

H PUNCH

HOLE

Punch hole

adjustment (paper

transport direction)

42 - 58 50 When the punch hole position

is shifted in the transport

direction, perform the

adjustment.

Punch

position

(Paper

transport

direction)

When the adjustment value is

increased, the punch position is

shifted to the paper lead edge side.

When t

he adjustment value is

decreased, the punch position is

shifted to the paper rear edge side.

0.2584mm

Loading...

Loading...