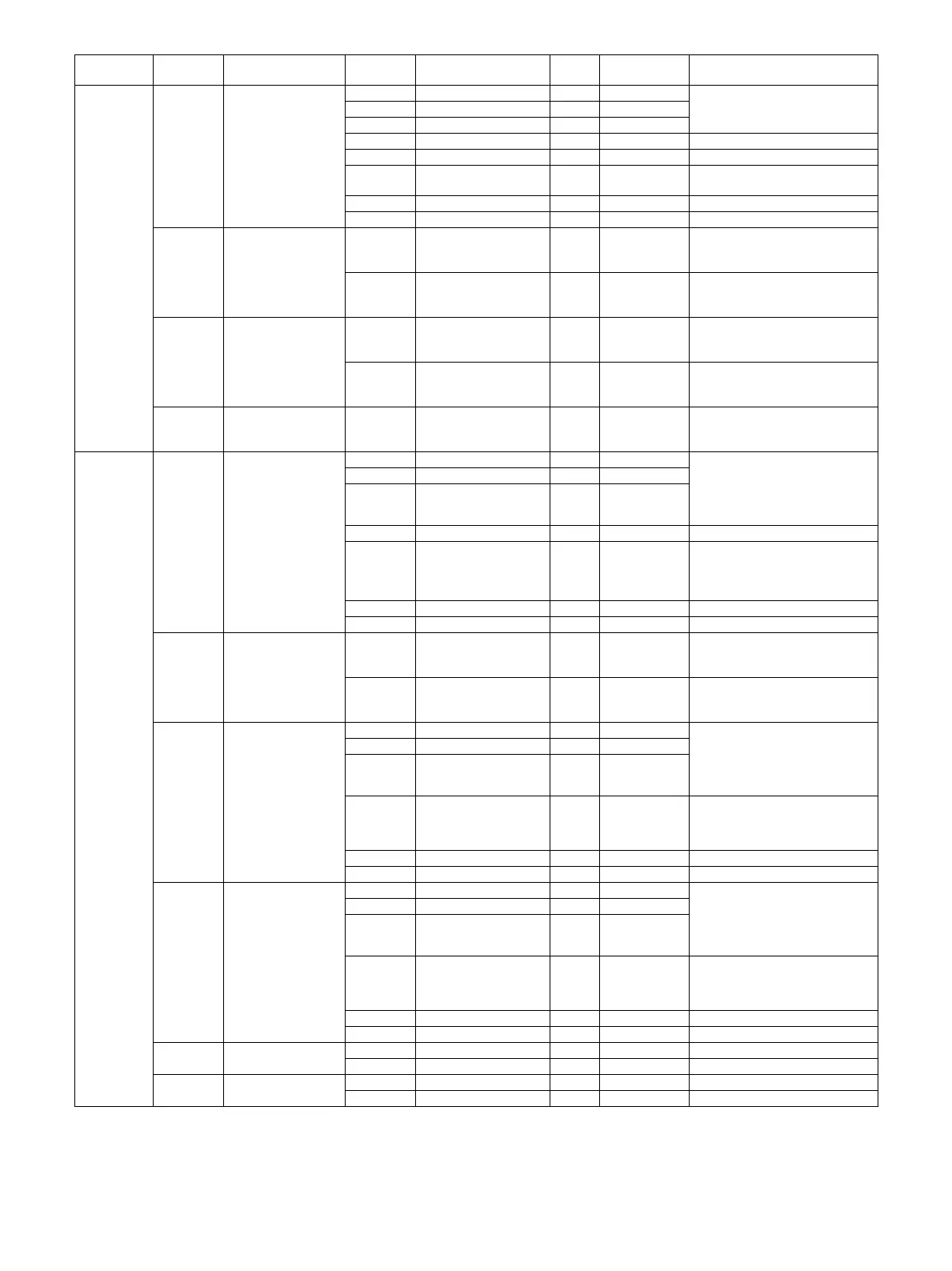

MX-3114N MAINTENANCE 9 – 15

Stand/

3x500 sheet

paper drawer

3 Tray 4 paper feed unit 14 Paper pickup roller ✕ Replace at 100K of each tray paper

feed counter or 1 year of use.

15 Paper feed roller ✕

16 Separation roller ✕

17 Vertical transport roller 2 ✕

18 Transport roller 5 ✕

19 Torque limiter ✕✕Replace at 100K of each tray paper

feed counter.

20 Sensors ✕✕

– Paper guides Clean with alcohol.

4 1CS drive unit 21 Gears (grease) ✕✕Apply to the specified position

when checking.

HANARL FL-955R

22 Shafts (grease) ✕✕Apply to the specified position

when checking.

FLOIL G-313S

5 2CS drive unit 23 Gears (grease) ✕✕Apply to the specified position

when checking.

HANARL FL-955R

24 Shafts (grease) ✕✕Apply to the specified position

when checking.

FLOIL G-313S

6 3CS drive unit 25 Shafts (grease) ✕✕Apply to the specified position

when checking.

FLOIL G-313S

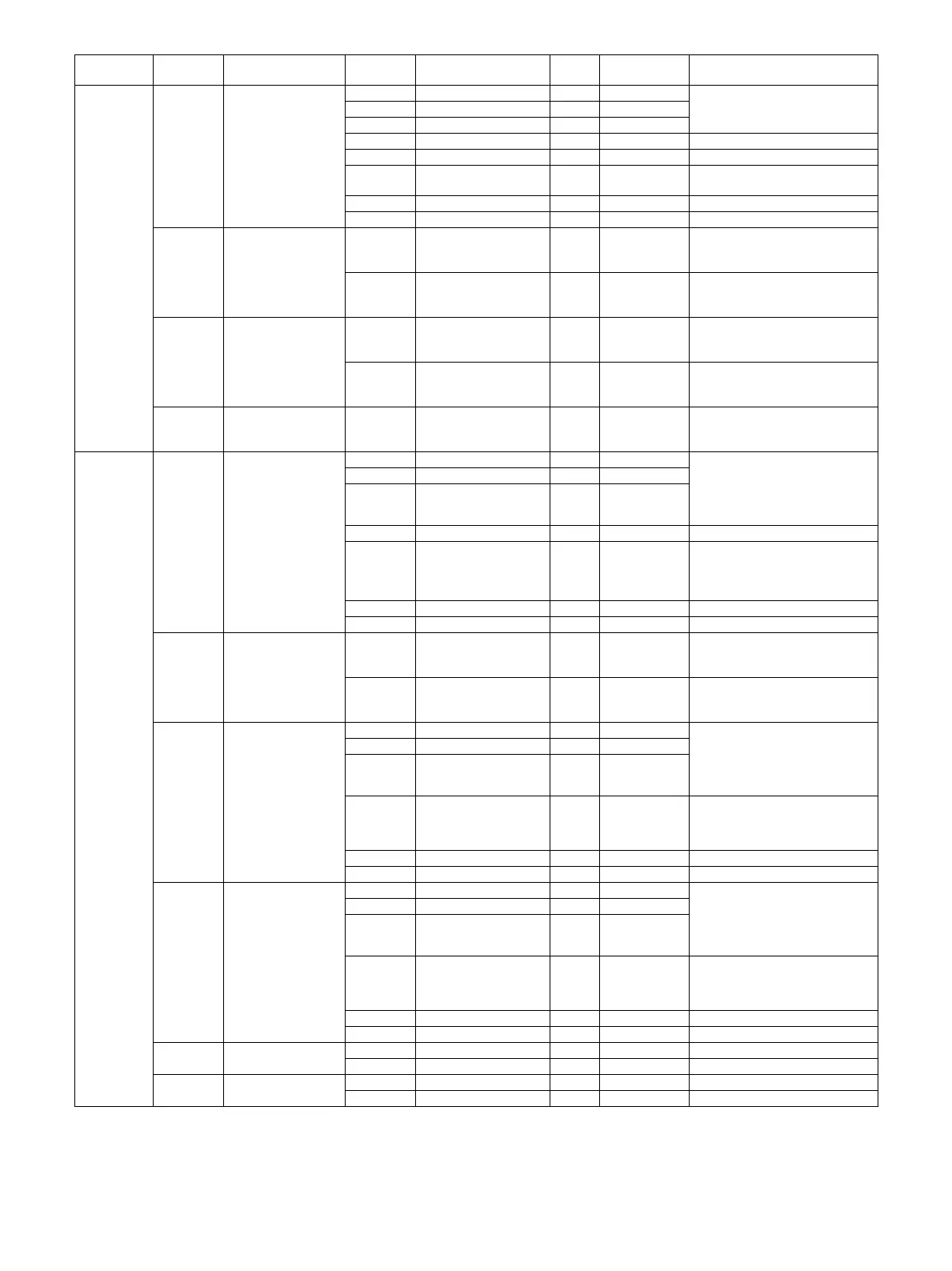

Stand/

500&2000

sheet paper

drawer

1 Tray 2 paper feed unit 1 Paper pickup roller ✕ As a rough guide, these rollers

should be replaced when each tray

paper feed counter reaches a value

of 100K or when one year has

elapsed since the start of use.

2 Paper feed roller ✕

3 Separation roller ✕

4 Transport roller 1 ✕

5 Torque limiter ✕✕As a rough guide, the torque limiter

should be replaced when each tray

paper feed counter reaches a value

of 100K.

6 Each sensor ✕✕

--- Each paper guide Clean with alcohol.

2 1CS drive unit 7 Each gear (grease) ✕✕When checking, apply to the

specified positions.

HANARL FL-955R

8 Each shaft (grease) ✕✕When checking, apply to the

specified positions.

FLOIL G-313S

3 Tray 3 paper feed unit 9 Paper pickup roller ✕ As a rough guide, these rollers

should be replaced when each tray

paper feed counter reaches a value

of 100K or when one year has

elapsed since the start of use.

10 Paper feed roller ✕

11 Separation roller ✕

12 Torque limiter ✕✕As a rough guide, the torque limiter

should be replaced when each tray

paper feed counter reaches a value

of 100K.

--- Each sensor ✕✕

--- Each paper guide

Clean with alcohol.

4 Tray 4 paper feed unit 13 Paper pickup roller ✕ As a rough guide, these rollers

should be replaced when each tray

paper feed counter reaches a value

of 100K or when one year has

elapsed since the start of use.

14 Paper feed roller ✕

15 Separation roller ✕

16 Torque limiter ✕✕As a rough guide, the torque limiter

should be replaced when each tray

paper feed counter reaches a value

of 100K.

--- Each sensor ✕✕

--- Each paper guide Clean with alcohol.

5 Level transport unit 17 Level transport roller R ✕

18 Level transport roller L ✕

6 Desk transport unit 19 Transport roller 2 ✕

20 Transport roller 3 ✕

Option

name

Unit work

sequence

Unit name

Parts work

sequence

Part name

When

calling

At the

machine cycle

Remark

Loading...

Loading...