MX-3114N ADJUSTMENTS AND SETTINGS 5 – 9

3) Enter the adjustment value (specified value), and press [OK] key.

When [EXECUTE] key is pressed, the voltage entered in the procedure 3) is outputted for 30sec and the set value is saved.

When [EXECUTE] key is pressed again, the output is stopped.

By setting the default value (specified value), the specified output is provided.

ADJ 3 Image density sensor

adjustment

Before executing this adjustment, check to confirm the following

items.

* Check to confirm that the color image density sensor (image reg-

istration sensor F) and the black image density sensor (image

registration sensor R) are clean.

* Check to confirm that the image density sensor calibration plate

is clean.

* Check to confirm that the transfer belt is clean and free from

scratches.

3-A Image density sensor adjustment

The transfer belt surface are used to make the sensitivity adjust-

ment of the color image density sensor (image registration sensor

F) and the black image density sensor (image registration sensor

R).

This adjustment executes automatically at the outset of registration

adjustment operation and process control operation as well as

SIM44-2.

Normally, therefore, it is not required to perform this adjustment. It

is performed only when the sensor is replaced or when the adjust-

ment result is checked.

1) Enter SIM44-2 mode.

2) Press [EXECUTE] key.

The sensitivity adjustments of the color image density sensor

(image registration sensor F) and the black image density sen-

sor (image registration sensor R) are automatically performed.

After completion of the adjustment, the adjustment result is

displayed and [EXECUTE] key returns to the normal display.

If the adjustment is not completed normally, "ERROR" is dis-

played.

When an error occurs, check the following sections for any abnor-

mality.

• Color image density sensor (image registration sensor F)

• Black image density sensor (image registration sensor R)

•PCU PWB

• Transfer belt (dirt, scratch)

• Transfer belt cleaner

If any abnormality is found, repair and adjust again.

If an error occurs, the adjustment result is not revised.

ADJ 4 Image lead edge position,

image loss, void area, image

off-center, image magnification

ratio adjustment

(Automatic adjustment)

The following adjustment items can be executed automatically with

SIM50-28.

*ADJ 15

Print image position, image magnification ratio, void area, off-

center adjustment (Print engine) (Manual adjustment)

*ADJ 16

Scan image magnification ratio adjustment (Manual adjustment)

*ADJ 17

Scan image off-center adjustment (Manual adjustment)

*ADJ 18

Copy image position, image loss adjustment

(Manual adjustment)

(Menu in SIM50-28 mode)

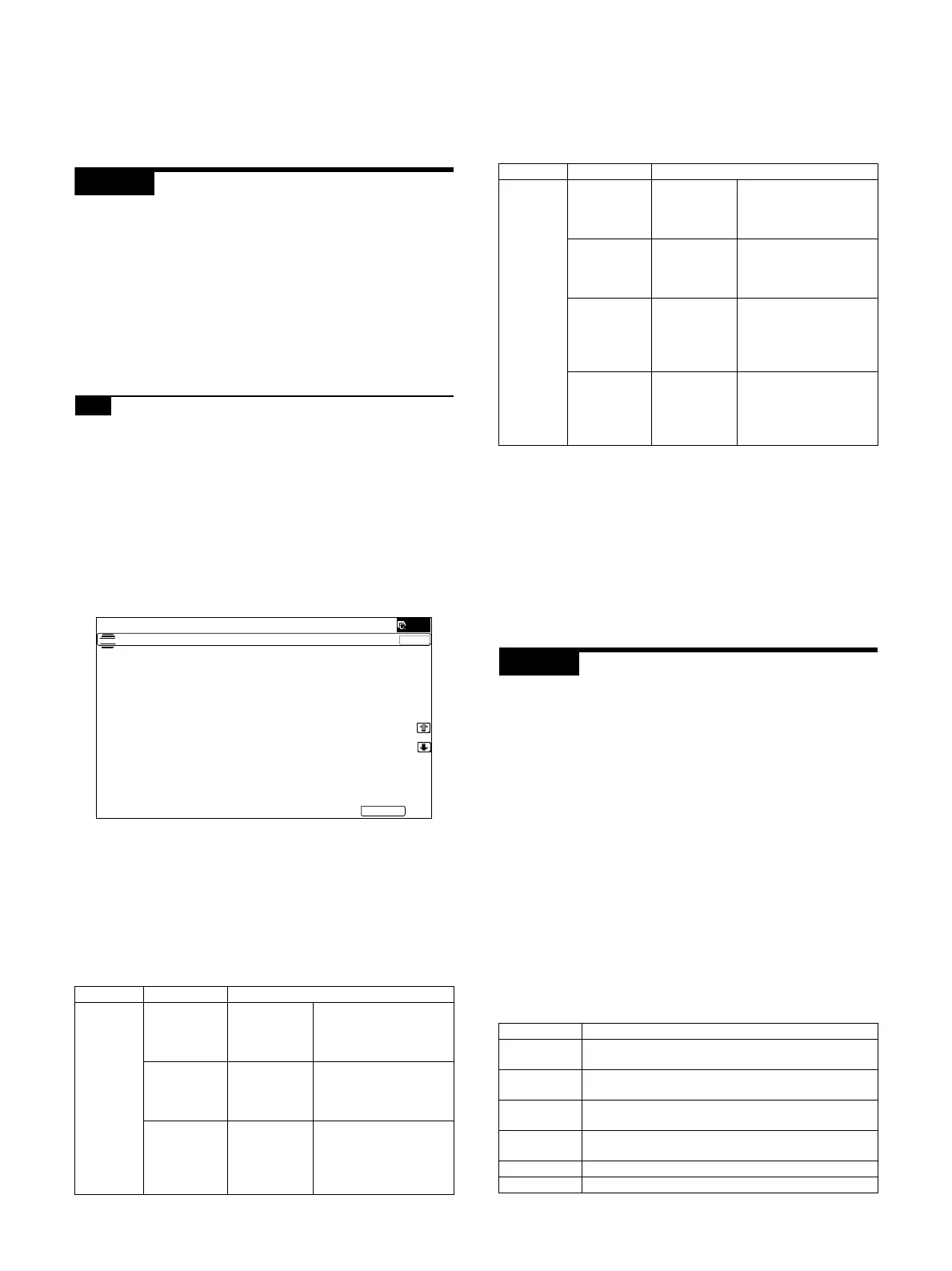

Mode Error display Error content

Adjustment

value for

process

control

operation

mode

BK_SEN_

ADJ_ERR

Black image

density sensor

adjustment

abnormality

PCS_K LED ADJ error

(The target value is not

obtained after retried

three times.)

CL_SEN_

ADJ_ERR

Color image

density sensor

adjustment

abnormality

PCS_CL LED ADJ error

(The target value is not

obtained after retried

three times.)

BELT_READ_

ERR

Transfer belt

surface

reading

abnormality

PCS_K GRND error (The

surface detection level is

maximum or the minimum

value difference is outside

a reference range.)

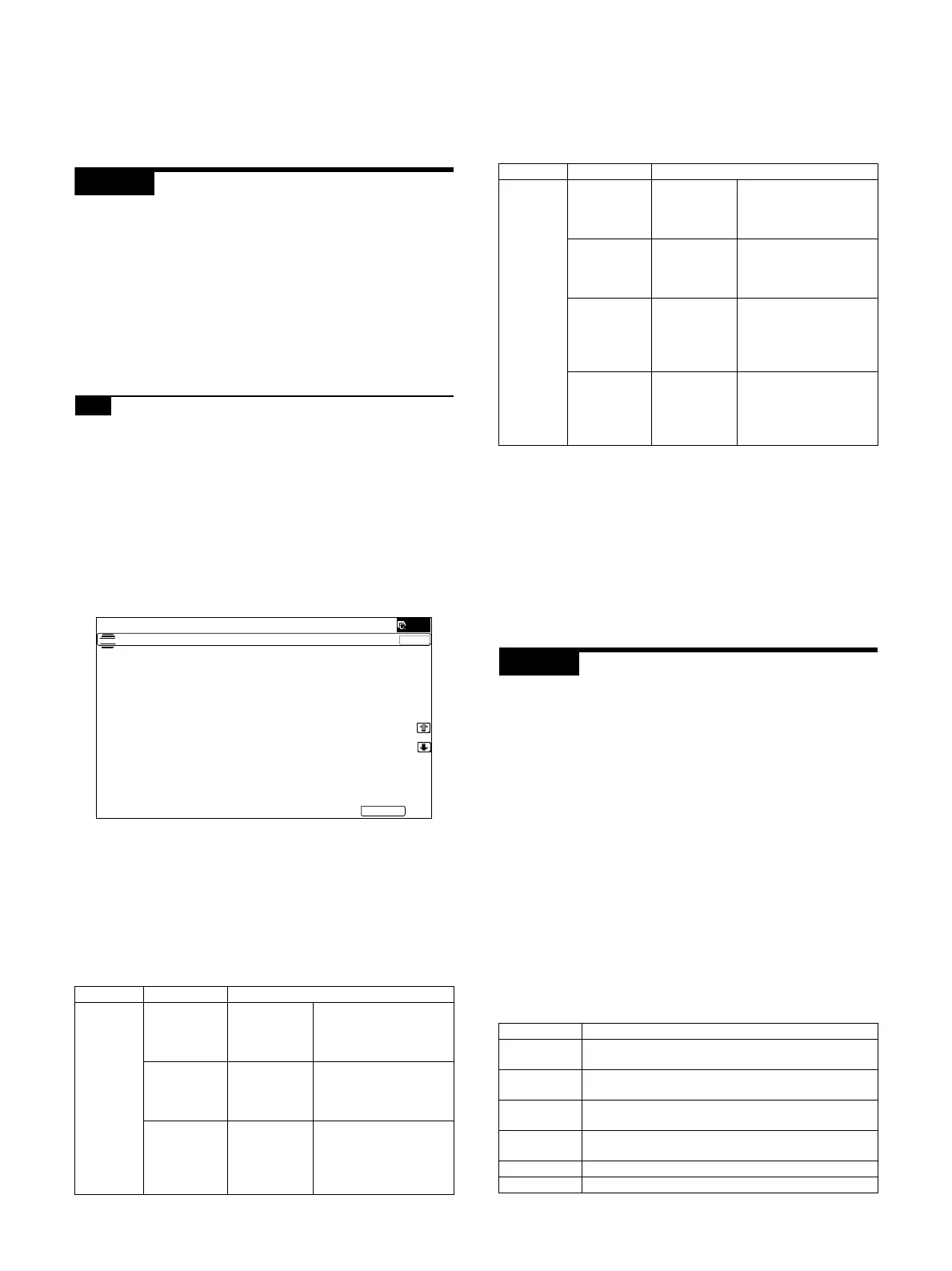

ǂǂǂ6,08/$7,21ǂǂ12

&/26(

7(67

352&21*$,1$'-8670(17

(;(&87(

3&6B&//('$'- 5(*B)*51'

3&6B./('$'- 5(*B5*51'

3&6B&/'$5. 5(*B)%(/70$;

3&6B.'$5. 5(*B)%(/70,1

3&6B.*51' 5(*B)%(/7',)

3&6B.%(/70$; 5(*B5%(/70$;

3&6B.%(/70,1 5(*B5%(/70,1

3&6B.%(/7',) 5(*B5%(/7',)

5(*B)/('$'- 5(*B)3$7&+.

5(*B5/('$'- 5(*B)3$7&+&

5(*B)'$5. 5(*B)3$7&+0

5(*B5'$5. 5(*B)3$7&+<

Adjustment

value for

image

registration

operation

mode

REG_SEN_

F_ADJ_ERR

Registration

sensor F

adjustment

abnormality

REG_F LED ADJ error

(The target value is not

obtained after retried

three times.)

REG_SEN_

R_ADJ_ERR

Registration

sensor R

adjustment

abnormality

REG_R LED ADJ error

(The target value is not

obtained after retried

three times.)

REG_BELT_

F_READ_

ERR

F side transfer

belt surface

reading

abnormality

REG_F GRND error (The

surface detection level is

maximum or the minimum

value difference is outside

a reference range.)

REG_BELT_

R_READ_

ERR

R side transfer

belt surface

reading

abnormality

REG_R GRND error (The

surface detection level is

maximum or the minimum

value difference is outside

a reference range.)

Display/Item Content

OC ADJ Image loss off-center sub scanning direction image

magnification ratio adjustment (Document table mode)

BK-MAG ADJ Main scanning direction image magnification ratio

adjustment

SPF ADJ Image loss off-center sub scanning direction image

magnification ratio adjustment (RSPF mode)

SETUP/

PRINT ADJ

Print lead edge adjustment, image off-center (each paper

feed tray, duplex mode) adjustment

RESULT Adjustment result display

DATA Display of data used when an adjustment is executed

Mode Error display Error content

Loading...

Loading...