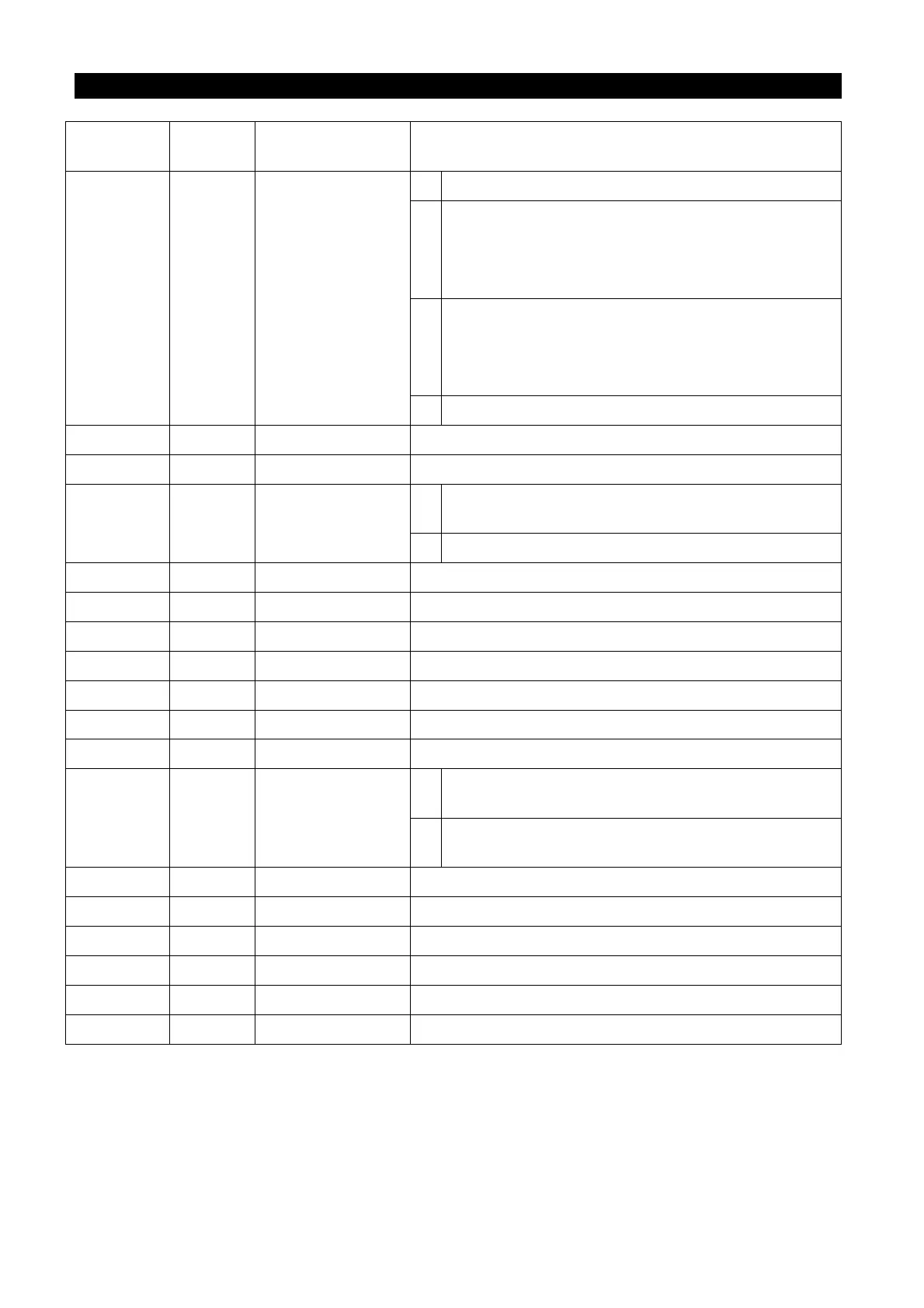

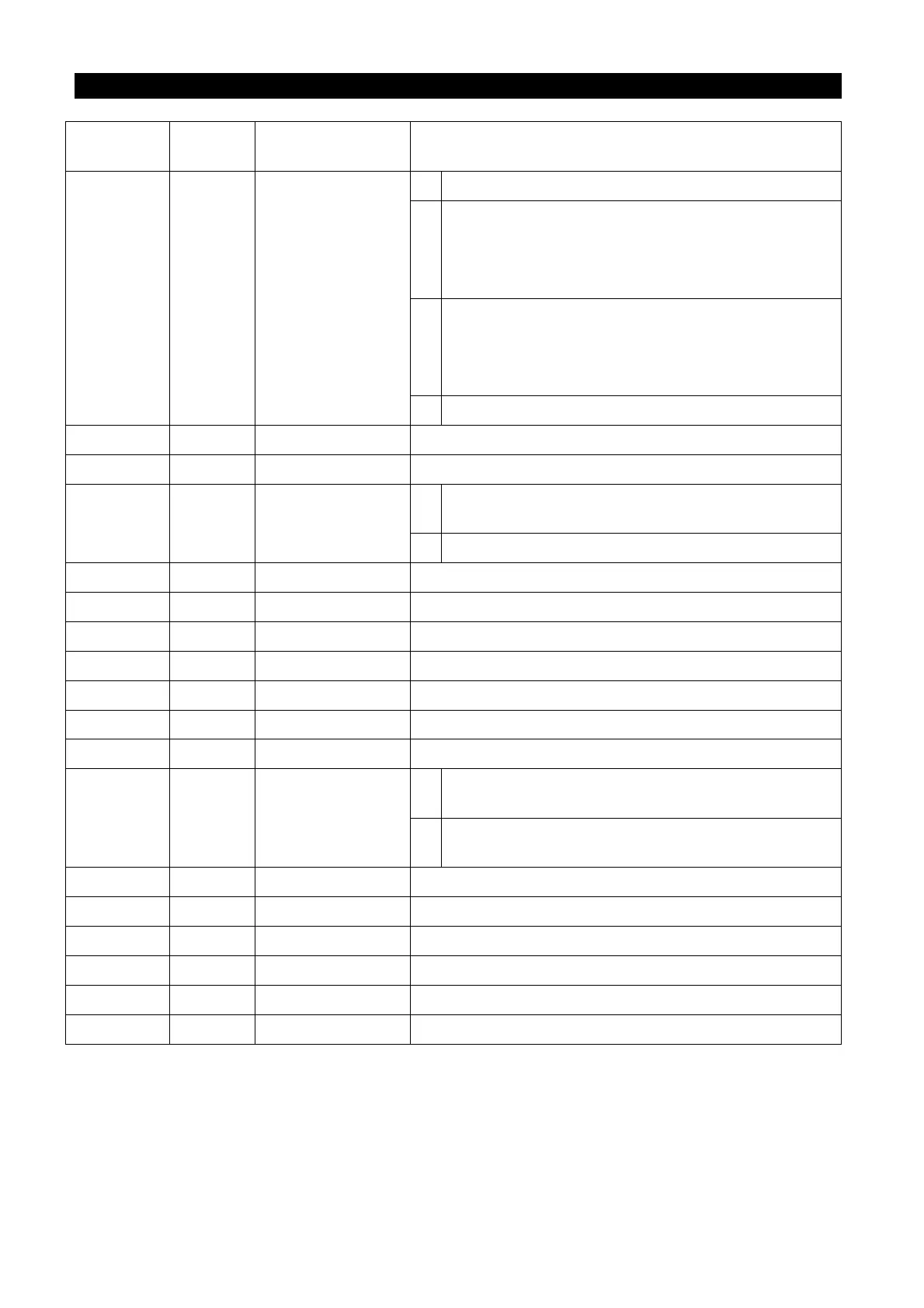

Parameter Description

613 0 0~1

0

Initial curling radius is set by the parameter

P.614~P.616.

1 Initial curling radius is set by the analog value.

614 100 1~10000mm Initial curling radius 1

615 100 1~10000mm Initial curling radius 2

616 100 1~10000mm Initial curling radius 3

617 0 0~31 Curling radius filtering coefficient

618 --- 1~10000mm Current value of curling radius

Number of pulses each turn

Number of turns each layer

621 0 0~1

0

The material thickness is set by the parameter

P.622~P.625.

1

The material thickness is set by the analog

value.

622 0.01 0.01~100.00mm Material thickness 0

623 0.01 0.01~100.00mm Material thickness 1

626 1.00 0.01~100.00mm Maximum thickness

650 0 0~1 Curling radius memory

<Setting>

• In every tension control method, the curling radius is needed to be calculated. The curling

radius can be acquired through the curling radius calculation module built in the inverter

or through the external curling radius sensor.

• P.610=0, the calculation through line speed: the curling radius is calculated by the system

Parameter

Setting range Remarks

610 0 0~3

Calculation through line speed

1

Calculation through thickness accumulation

(the encoder on side of the motor), the pulse

signal is connected to the A1/B1 on PG03

card.

2

Calculation through thickness accumulation

(the encoder on the side of curling shaft), the

pulse signal is connected to the high-speed

pulse input terminal HDI.

3 Analog value or pulse input

611 500 1~10000mm The maximum curling radius

612 100 1~10000mm Winding shaft diameter

Loading...

Loading...