Parameter Description

current line speed and the inverter output frequency. The equation is as follows:

Wherein D is the curling radius, I is the mechanical transmission ratio, V is the line speed, n

is the motor speed.

When the system operation speed is slow, the line speed of material and the output

frequency of the inverter will be low. Then a little detection error will cause a big error in the

curling radius calculation, so that a lowest line speed P.629 must be set. When the line

speed of material is lower than P.629, the curling radius is stopped to calculate and the

current value of curling radius remains unchanged. The value should be set below the

normal working line speed.

• P.610=1, the calculation of thickness accumulation: the curling radius is worked out through

the encoder on the motor side and the gear feedback. In this condition, connect the pulse

signal to A1/B1 on PG03 and set the encoder input mode setup (P.351), the mechanical

transmission ratio (P.603), the number of pulses per revolution of the encoder (P.350), the

number of turns each layer (P.620) and the material thickness 0 (P.622).

• P.610=2, the calculation through thickness accumulation: the curling radius is worked out

through the encoder on the winding shaft. In this condition, connect the pulse signal to

the terminal HDI of the inverter and calculate the curling radius through the number of

pulses each turn (P.619), the number of turns each layer (P.620) and the material

thickness 0 (P.622).

• P.610=3, when testing the curling radius with curling radius test sensor, the input channel of

curling radius sensor can be the analog value or the pulse input.

• P.611 is used to set the maximum curling radius. When P.610=3, the parameter must be set

and the maximum of the analog value or pulse signal corresponds to the set value of the

parameter P.611.

• P.612 is used to set the winding shaft diameter. The curling radius calculated by the curling

radius calculation module of the inverter is limited by P.611 and P.612.

• P.613 is used to select the input channel of initial curling radius.

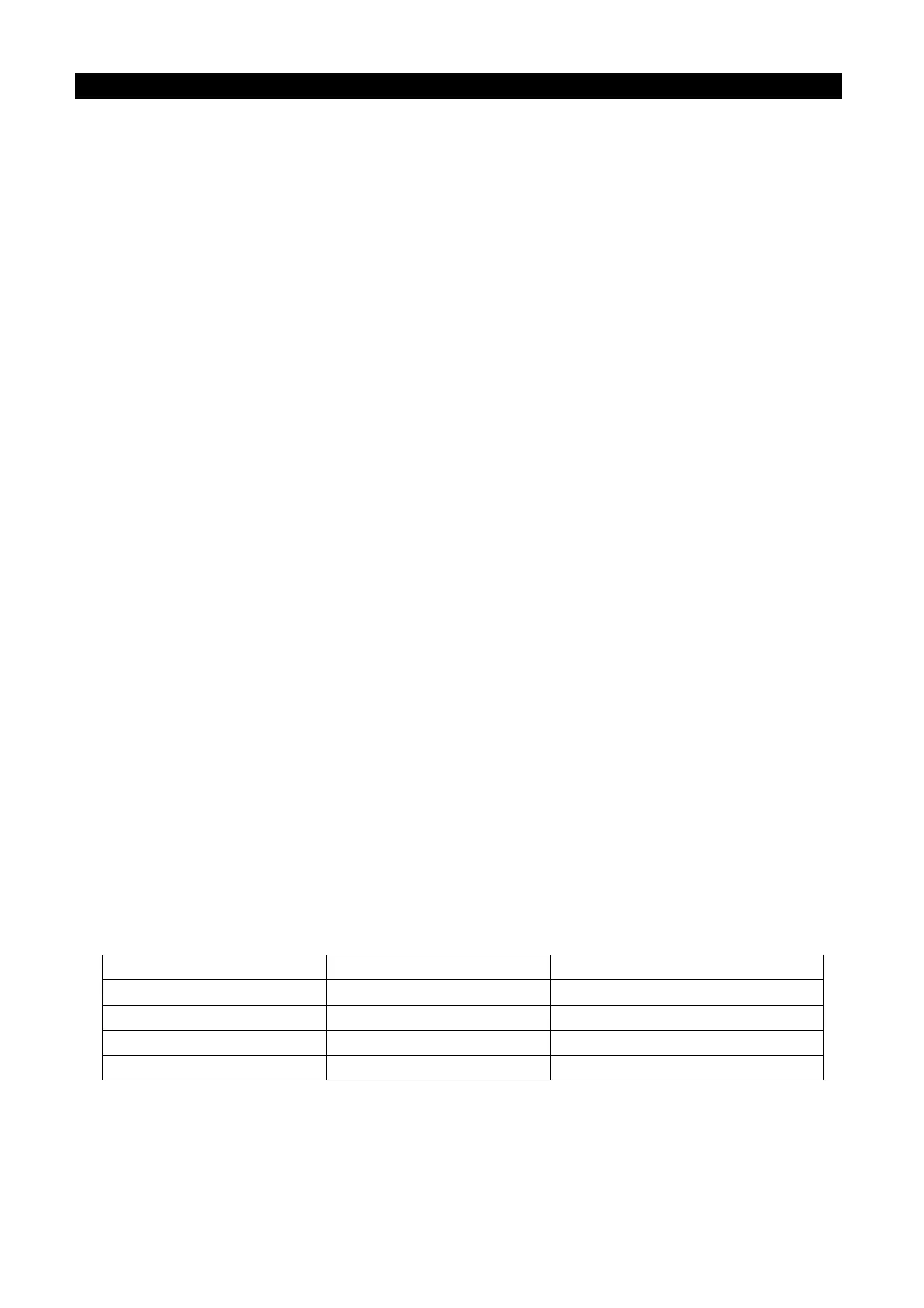

1) When P.613=0, the initial curling radius is set by the parameter P.614~P.616. The initial

value of curling radius can be determined through two multi-function terminals, the

selection of initial curling radius is as follows:

The initial curling radius source

2) When P.613=1, the initial curling radius is determined by the analog value. When the

initial curling radius does not count from the hollow curling radius, the initial curling

radius can be selected by the external terminal. For wind-up control, the system

default initial curling radius is the diameter of winding shaft (P.612). For roll-down

control, the system default initial curling radius is the maximum curling radius

Loading...

Loading...