26 FLOWSIC100 Flare · Operating Instructions · 8013344/11L2/V 2-5/2018-10 · © SICK Engineering GmbH

Product Description

Subject to change without notice

2.1.2 System configuration

The following figures show cross-duct installations (FLOWSIC100 EX/ EX-RE, EX-S). In

principle,

the configuration is also valid for single side installations (FLOWSIC100 EX-PR).

Configuration Description

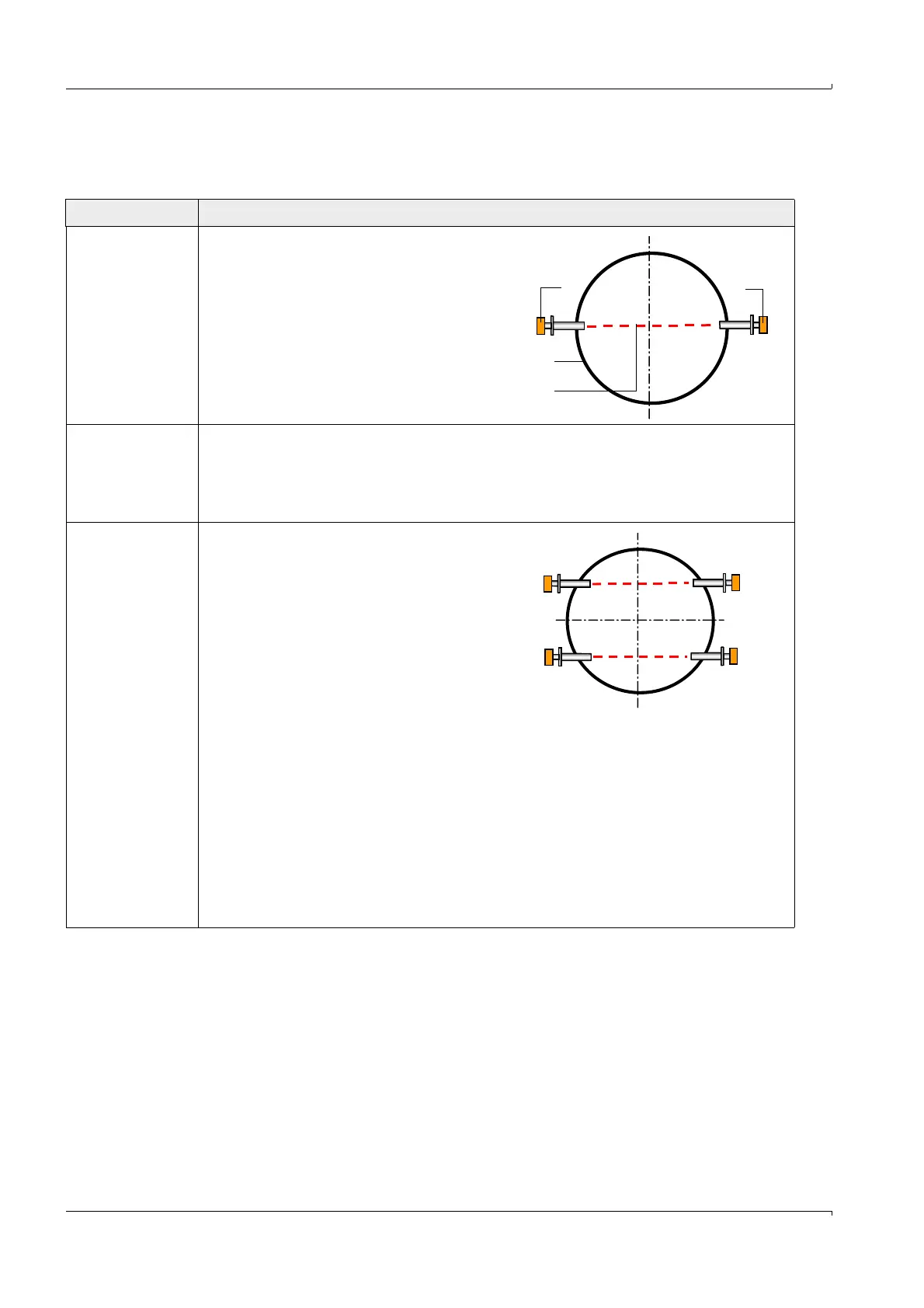

1-path

measurement

2 sender/receiver units (1) are mounted on

the pipeline (2). The measurement path (3)

is positioned across the center of the

pipeline.

Special application conditions can require a

path positioning outside the center of the

pipeline (shortening of active measuring

path).

Instead of 2 sender/receiver units also a

probe version can be used (type EX-PR).

2x1-path

measurement

In this configuration the control unit MCUP serves two independent 1-path measurement

systems. Both pairs of sender/receiver units are connected to the same control unit MCUP.

Separate processing and output of the measuring results for both measuring points is

performed by the MCUP. Preferably both measurements are installed like standard 1-path

measurements in the center of the pipeline.

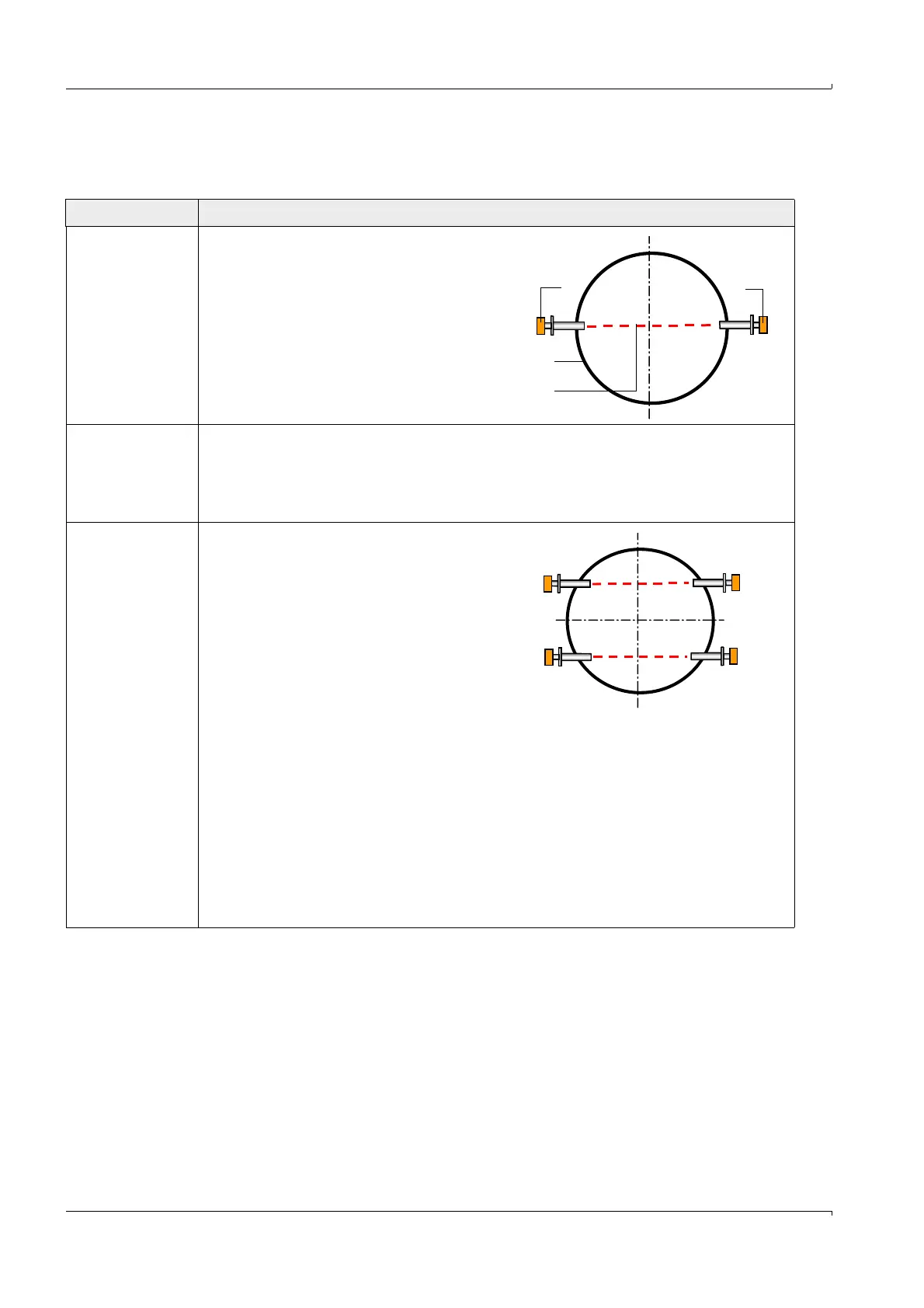

2-path

measurement

Two pairs of sender/receiver units are

installed at the same measuring location

and are connected to the same control unit

MCUP.

Both measurement paths should preferably

be positioned outside the center of the

pipeline and run parallel to one another.

Computation of both measuring paths to

one measuring result is performed via the

MCUP.

Two-path measurement is used to achieve higher measuring precision or for complicated

flow conditions.

Path compensation

The device is uses an integrated algorithm for path compensation in the case of a path

failure.

In trouble-free function, the system learns the relation of gas velocity and sound velocity

between both measurement paths. In case of a path failure, the system can calculate

theoretical values on basis of the learned path relations and can replace the invalid values

against them. In this way the path failure can be temporarily compensated and the

measurement is continued with slightly increased uncertainty. Under such conditions, the

measurement system automatically signals "Maintenance request".

Loading...

Loading...