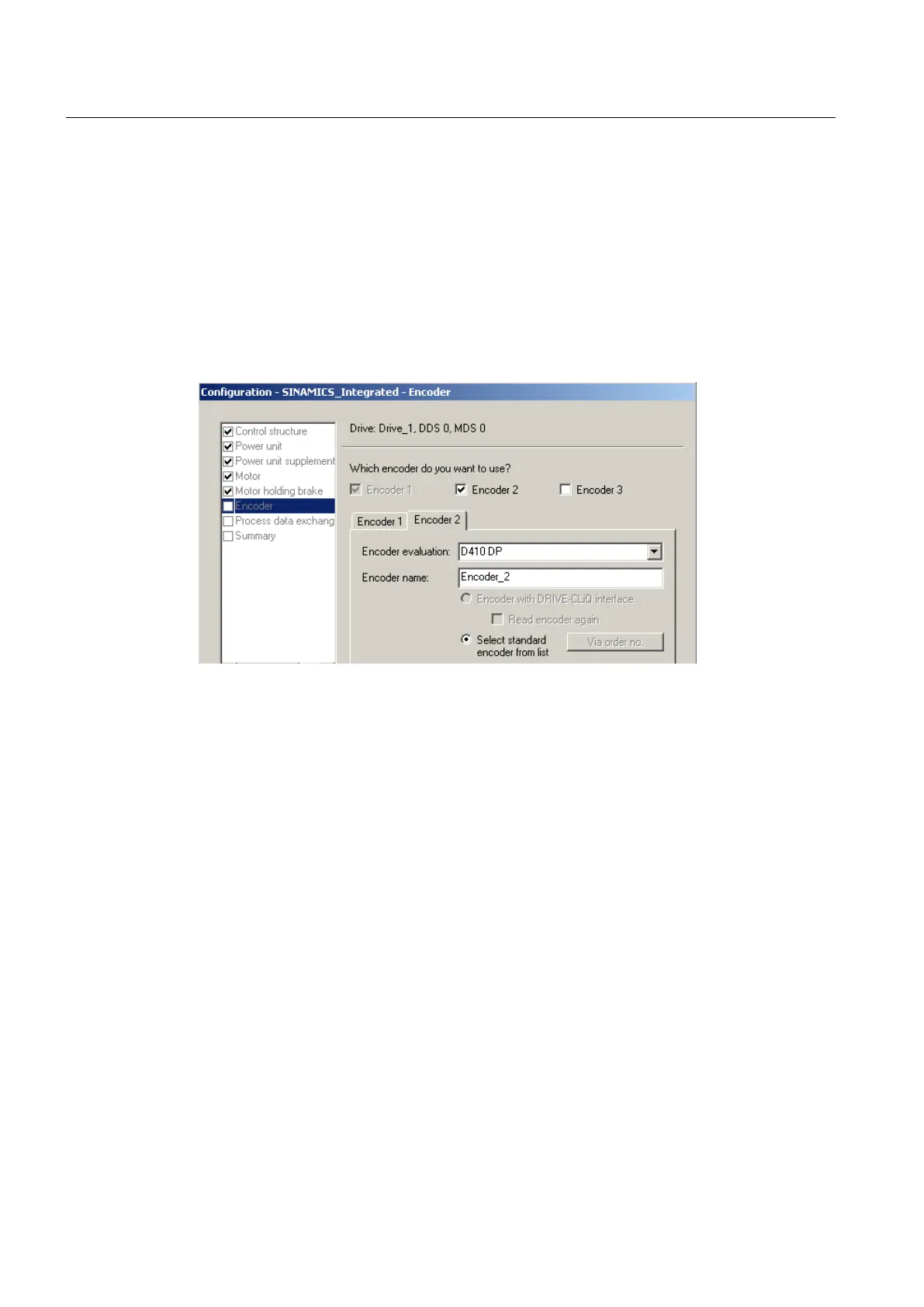

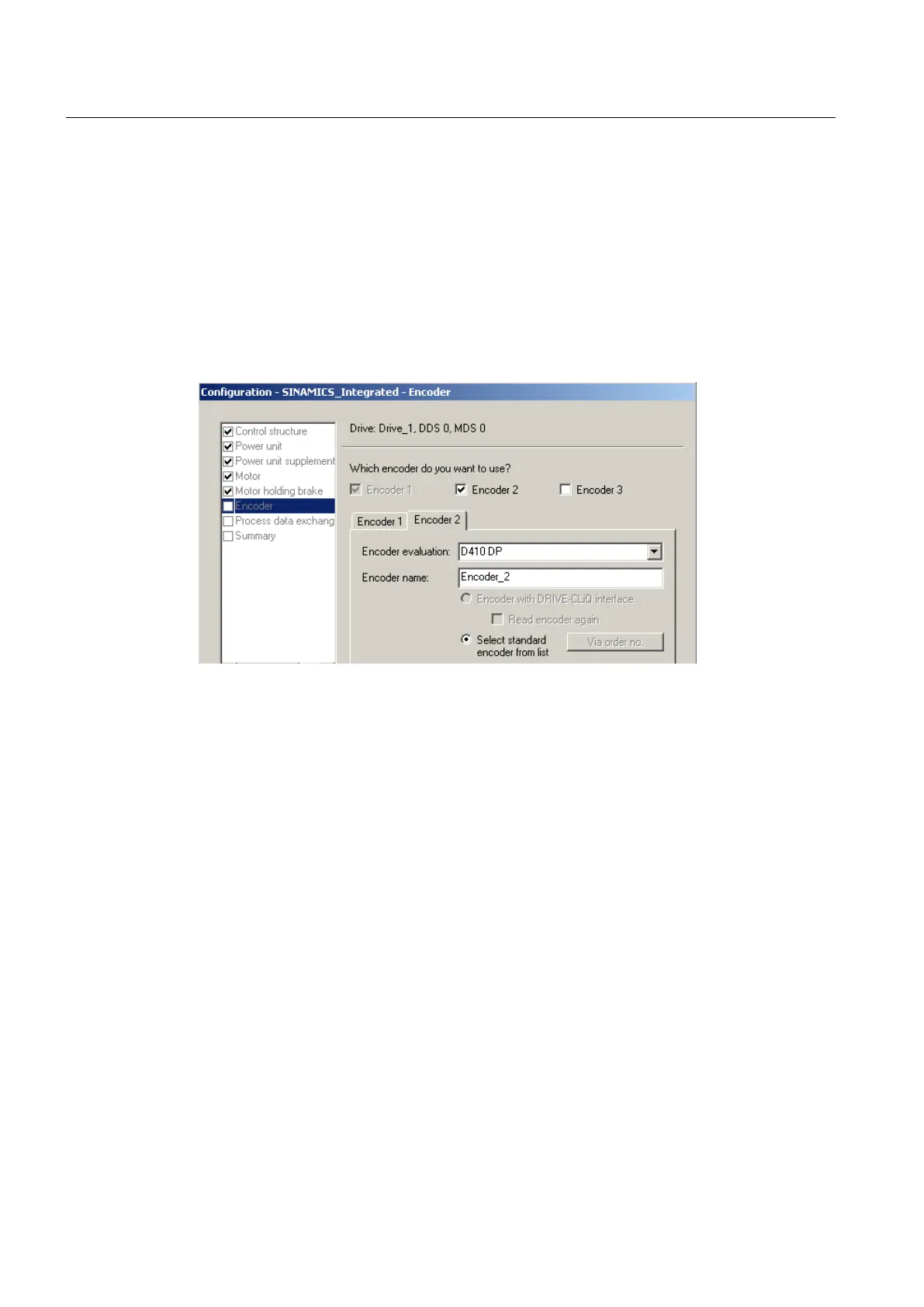

5.8.2 Configuring additional encoders on the drive

Second encoder on the drive

The

configuration of a second encoder on the drive is useful when the second encoder value

is also to be used for this drive (e.g. motor or machine encoder). Note that a maximum of only

two encoder values can be transferred via PROFIdrive message frames.

In principle the second encoder value can be used for any purpose (such as for recording an

external master value via the technology object "External encoder").

Figure 5-26 Configuration of a second encoder on the drive

5.8.3 Connecting additional encoders via PROFIBUS/PROFINET

Additional encoders for encoder integration can also be connected via PROFIBUS or

PROFINET. The following options are available:

● Encoder interconnection using a PROFIdrive message frame (encoder with message frame

types 81 and 83)

● Encoder interface as a direct value in the I/O area

Additional references

Detailed information is contained in the

SIMOTION TO Axis, Electric/Hydraulic, External Encoder

Function Manual

Commissioning (software)

5.8 Integrating additional encoders (optional)

SIMOTION D410

126 Commissioning Manual, 04/2014

Loading...

Loading...