10.03

1.2 Comparison of electric and hydraulic drive systems

1-16

Siemens AG, 2003. All rights reserved

SINUMERIK 840D/SIMODRIVE 611 digital, HLA Module (FBHLA) - 10.03 Edition

1.2 Comparison of electric and hydraulic drive systems

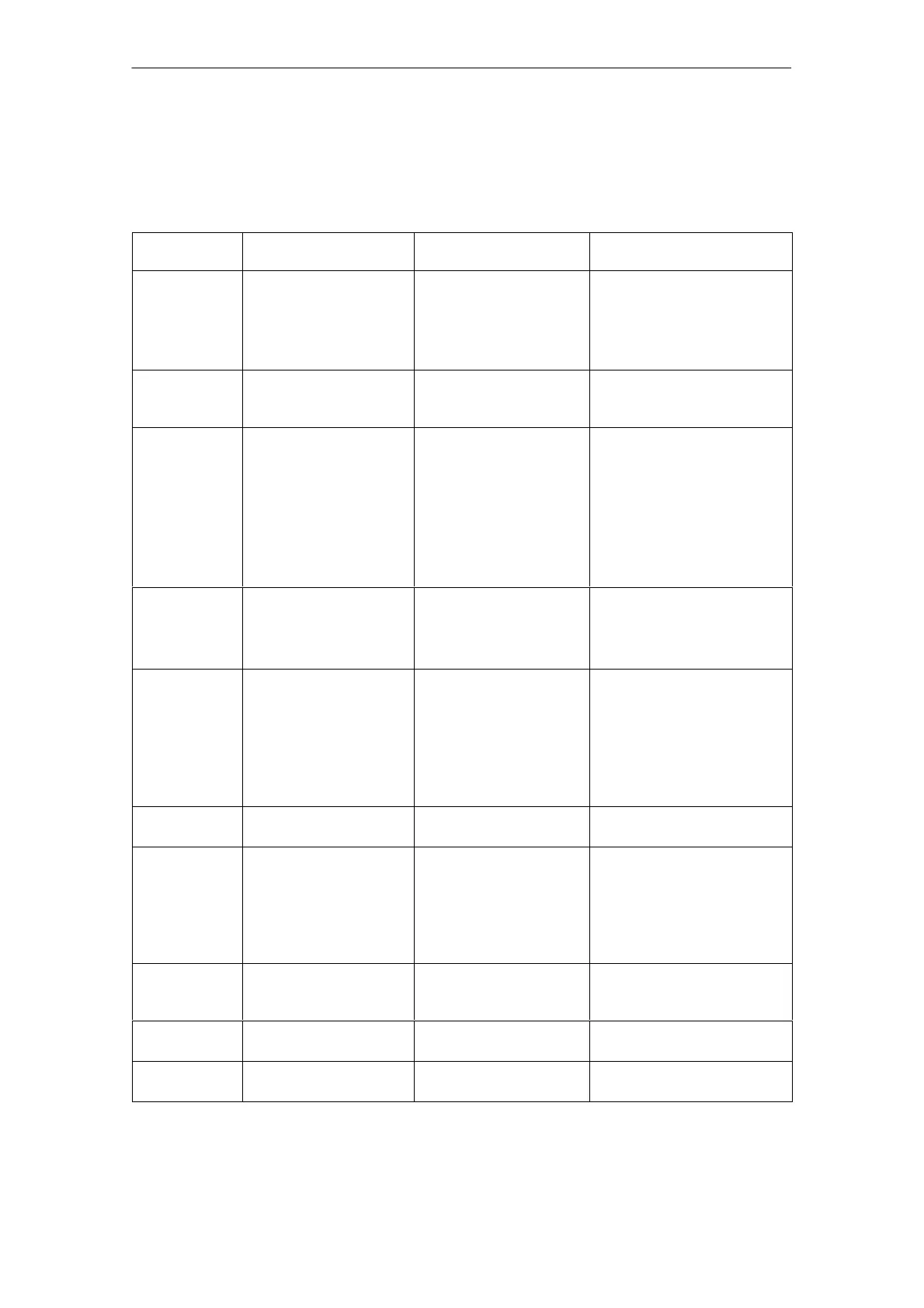

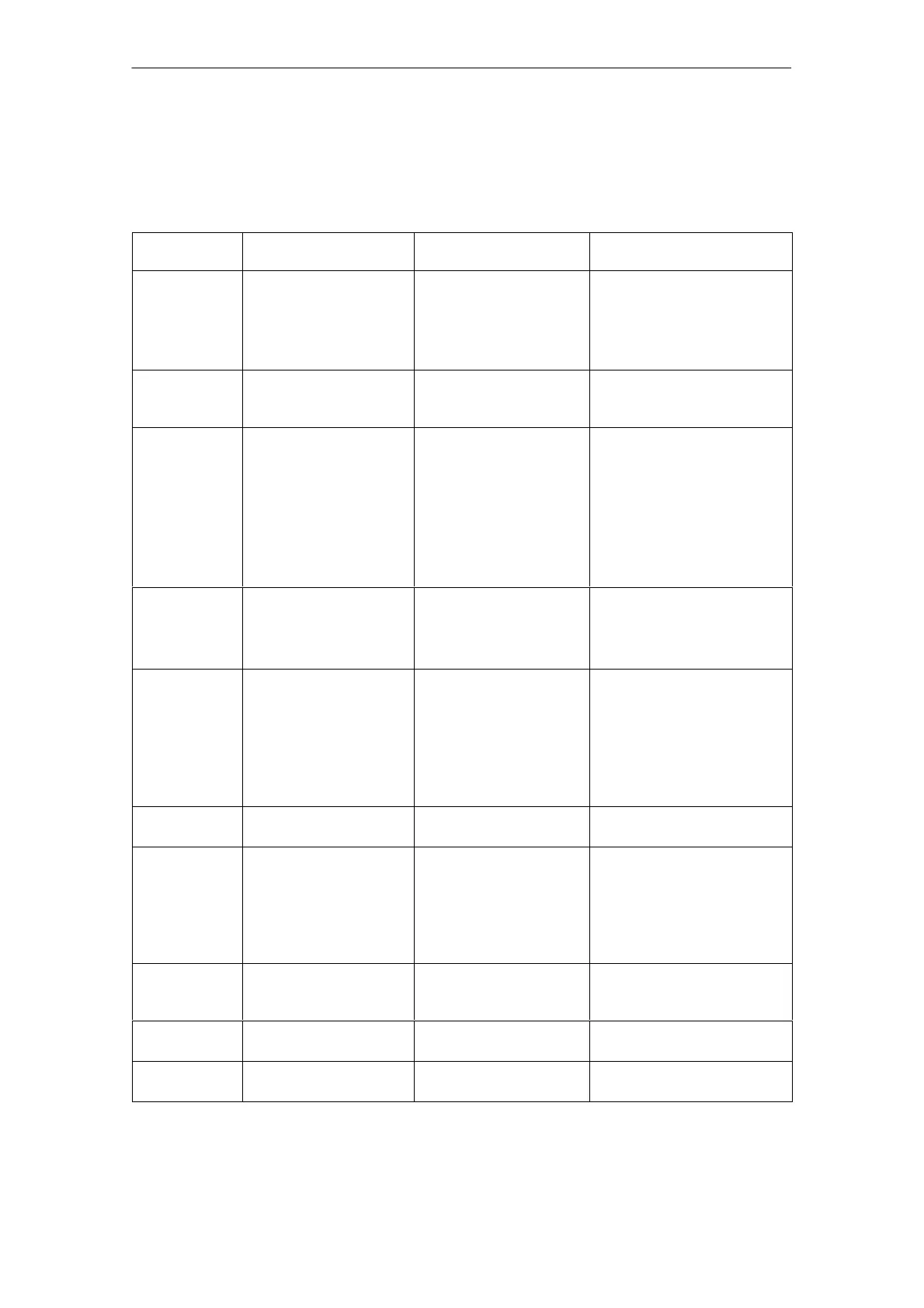

Table 1-1 Comparison of electric and hydraulic drive systems

Criterion Electric direct drive Electric drive with

leadscrew

Hydraulic drive

Power density /

mounting

space require-

ments

S Low weight and

S reduced spatial re-

quirements of the

electric part on the

machine table.

S Servomotor and leads-

crew large and heavy.

S Problematic with lim-

ited mounting space.

S Cylinder and servo sole-

noid valve are light-weight

and compact.

S Transfer of E motor to

hydraulic power unit.

Mass inertia of

moving parts

Electric part on machine

table has low mass.

Servomotor and leads-

crew have high mass mo-

ment of inertia.

Piston and piston rod have

very low mass

Operational

reliability,

service life

Service life depends in

principle only on linear

guides.

S Shock-sensitive.

S Service life limited by

leadscrew.

S Sudden failure

possible.

S Protected against overload

by pressure limitation.

S Sturdy, insensitive to

shocks.

S Cylinder seals and valve

control edges have long

service life.

S Warning of wear.

Servicing Simple replacement Expensive replacement

and repair of leadscrew by

specialists.

S Simple error diagnosis

S Simple replacement and

repair of valves and cylin-

ders.

Energy storage Peak requirement must

be installed as no storage

is possible.

Peak requirement must be

installed as no storage is

possible.

S Compensation of energy

requirement peaks by hy-

draulic accumulator.

S Rapid traverse in differen-

tial circuit.

S Reduction of installed ca-

pacity.

Maximum

forces

Peak thrust per unit area

approx. 40 to 80 kN/m

2

Restriction with larger

forces.

Practically unlimited

(cylinderφ, p

max

=700 bar)

Load stiffness Very good;

Servo gain can be set to

betw. 10-100 times

higher than on the other

two drives.

S Elasticity under large

forces.

S Elasticity of leadscrew

is largely compen-

sated as a control

function.

S Oil compressibility is com-

pensated as a control

function (I component).

S Good zero overlap quality

of valve ensures very high

rigidity under load.

maximum ve-

locity

Up to 500 m/min v

max

=h

s

@ ω

max

/2π

h

s

=thread lead

ω

max

=max. motor speed

30...300 m/min

(depending on which cylinder

seal kit is used)

Maximum

travel path

Unlimited

v 6 m v 3 m

Collision

protection

Mechanically difficult Mechanically possible Mechanically possible

Loading...

Loading...