10.03

3.11 Start-up functions

3-88

Siemens AG, 2003. All rights reserved

SINUMERIK 840D/SIMODRIVE 611 digital, HLA Module (FBHLA) - 10.03 Edition

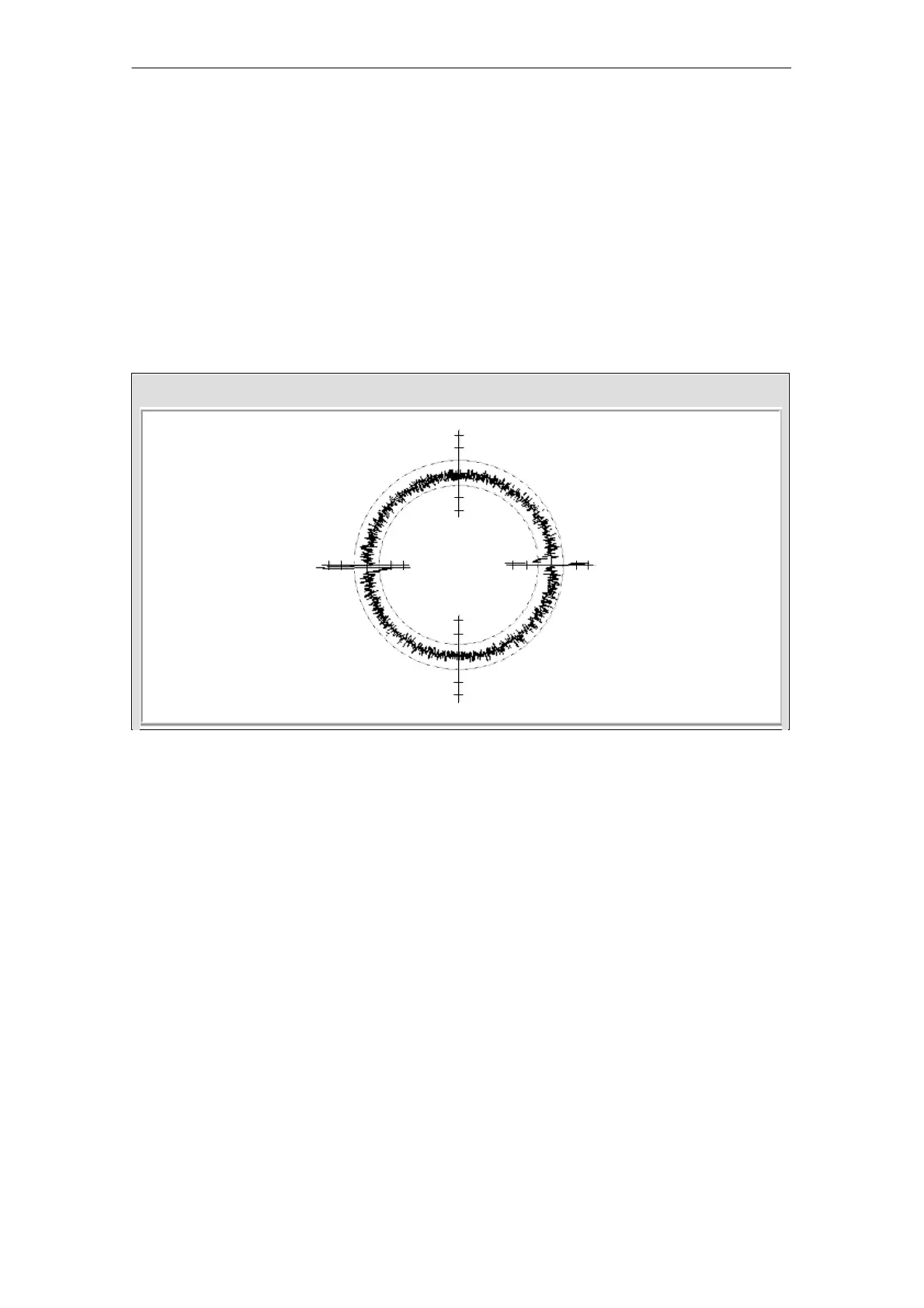

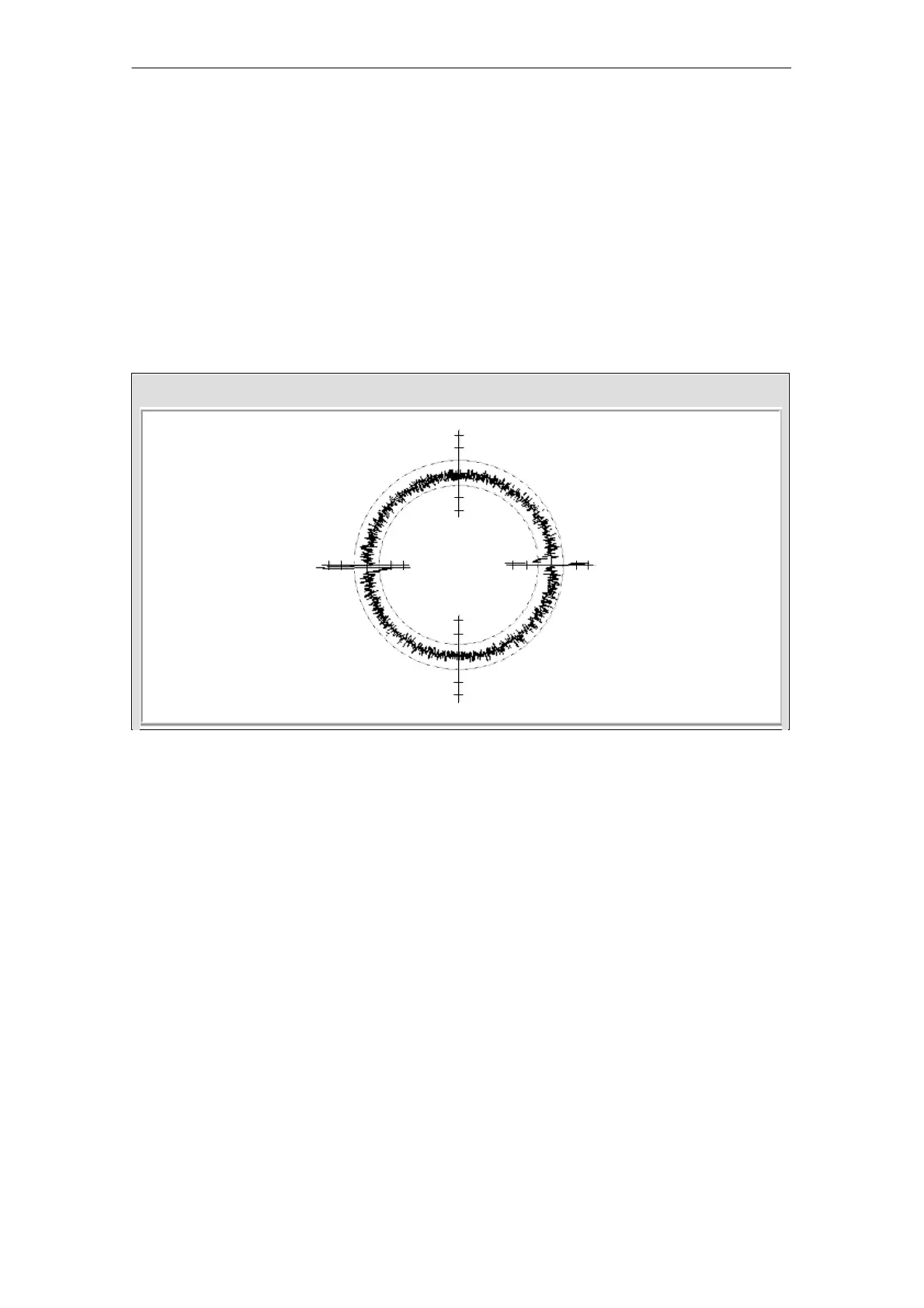

3.11.3 Circularity test

The circularity test is used among other things as a way of checking the result-

ing contour precision. It works by measuring the actual positions during a circu-

lar movement and displaying the deviations from the programmed radius as a

diagram (especially at the quadrant transitions). For detailed information, see:

References: /FB/Part 2, K3, Sect. 2.7 “Circularity test”

Example: The following example refers to a drive with an HRV.

X1 axis: Horizontal movement by electric drive

Y1 axis: Vertical movement by hydraulic drive

Scl/Div = 1.000e-03 Radius = 19.999

Tr. 1: X1 axis: Circularity test (electric axis)

Tr. 2: Y1 axis: Circularity test (hydraulic axis)

Fig. 3-41 Example of circularity test on HRV size 06, 15 l/min, knee-point 60%; V=400 mm/min (traversing velocity)

3.11.4 Servo trace

The servo trace function is used for graphic representation of signals and oper-

ating conditions.

A hydraulic-specific signal list (servo and drive signals) is available as a support

function for axes with HLA module.

The following hydraulic-specific drive signals are supported by the servo trace:

S Active power (with pressure sensing)

S Actual force (with pressure sensing)

S Actual velocity value

S Valve stroke setpoint

S Actual valve stroke

S Actual pressure cylinder A end

S Actual pressure cylinder B end

04.00

Loading...

Loading...