10.03

3.9 Fine adjustment and optimization

3-63

Siemens AG, 2003. All rights reserved

SINUMERIK 840D/SIMODRIVE 611 digital, HLA Module (FBHLA) - 10.03 Edition

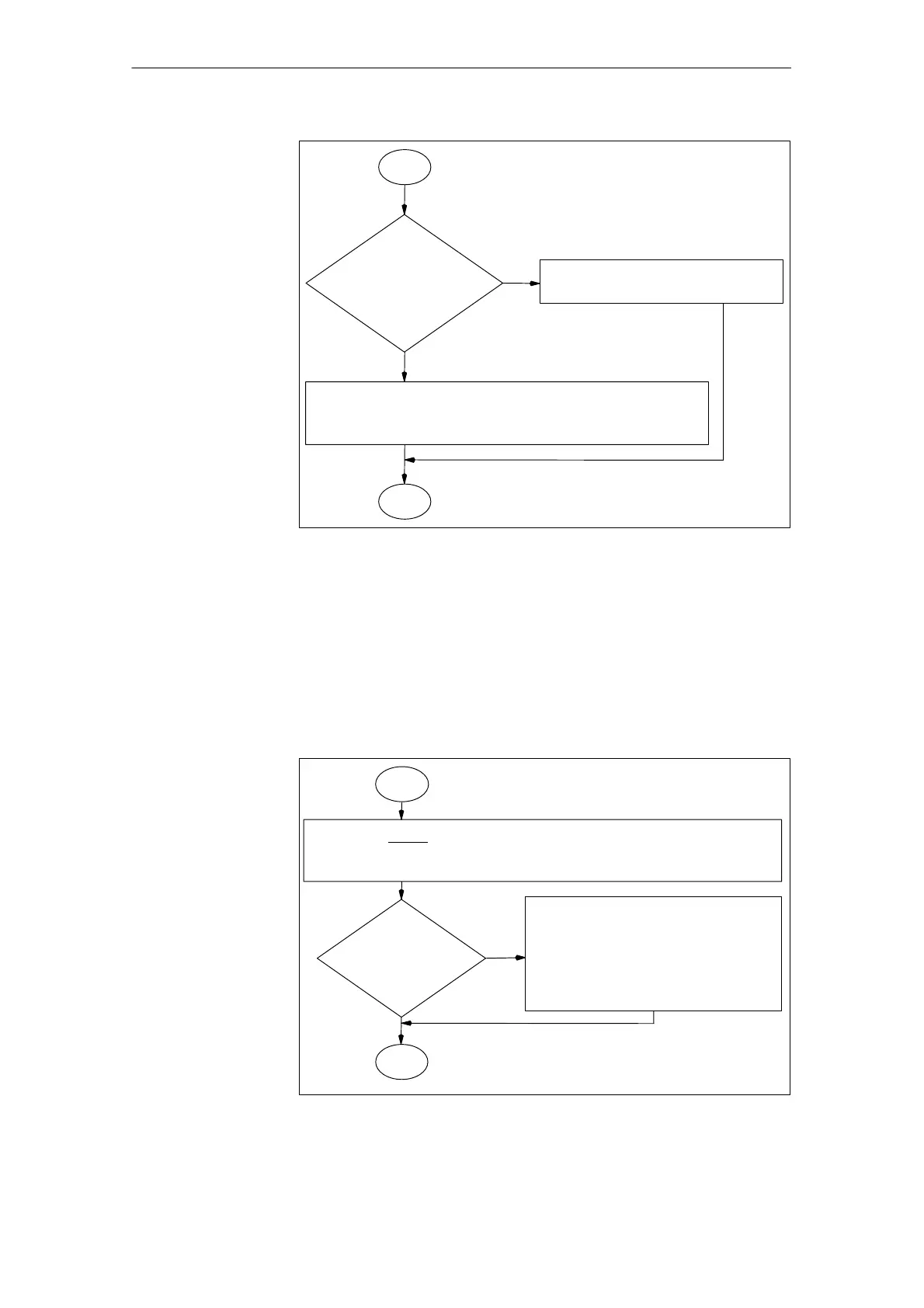

MD 32110: Modify ENC_FEEDBACK_POL (actual value sign)

or MD 5476: Invert OUTPUT_VOLTAGE_INVERSION (manip. variable

inversion) and MD 5011: invert ACTUAL_VALUE_CONFIG (actual value

sensing)

Step 2

MD 5476: Invert

OUTPUT_VOLTAGE_INVERSION (manip.

variable inversion)

no

yes, but fails with error message

Do MD 5706 and

MD 5707 (v

set

, v

act

)

have the same sign

when the drive

starts?

Start

Fig. 3-17 Start-up flow chart, determine control direction

When the cylinder piston moves in the A ³ B direction (flow rate Q > 0) , the

actual velocity value V

act

must be positive.

This definition MUST be made in the drive for the associated functionality of

S velocity controller adaptation and

S force limitation

absolutely essential.

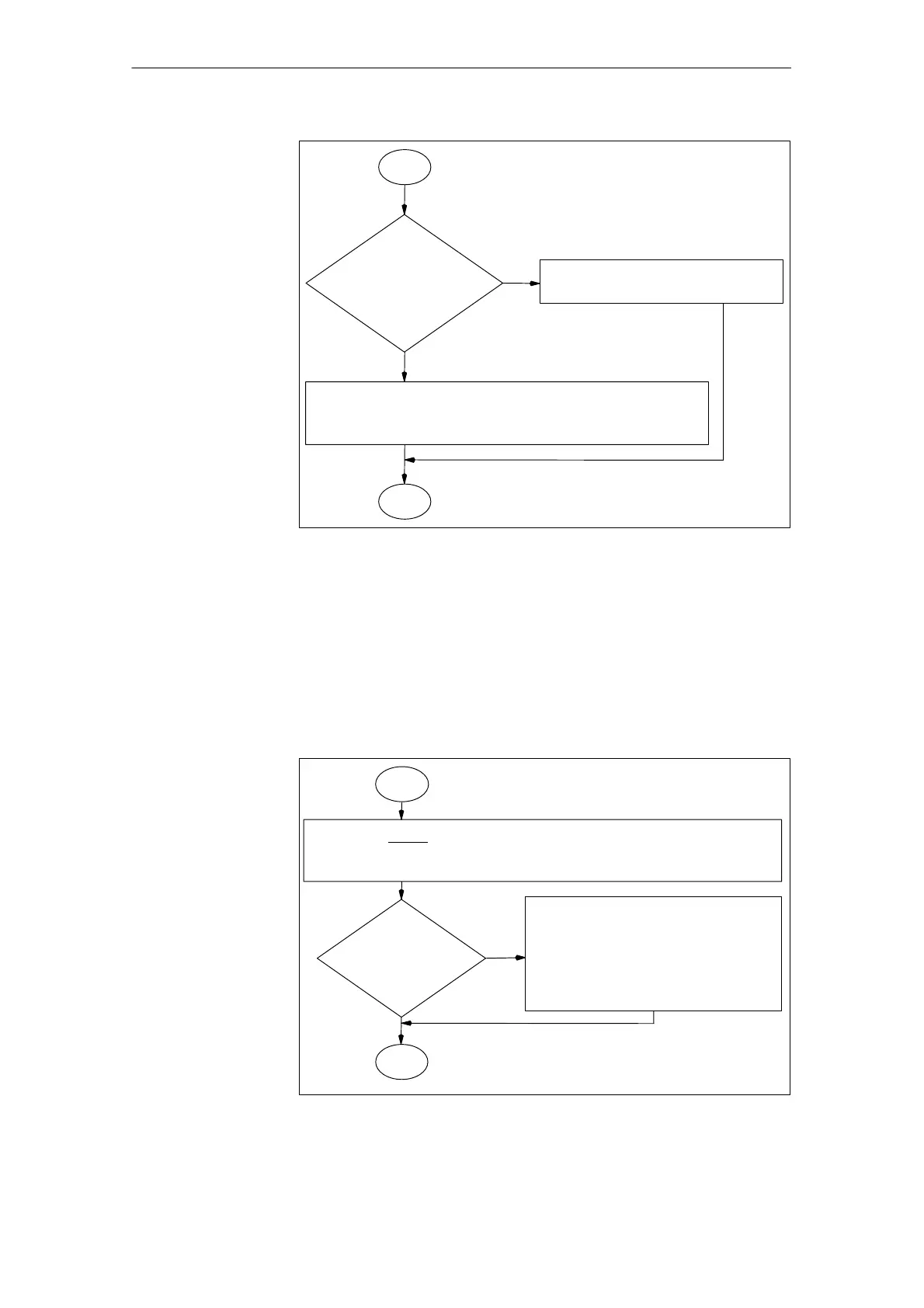

Enter a small positive valve manipulated voltage (function generator)

or

traverse the drive in JOG mode to move the cylinder piston from the A to B end.

no

Yes

Is cylinder

piston A ! B traversing

and is MD 5707

positive?

Step 3

Step 2

MD 5476: OUTPUT_VOLTAGE_INVERSION

Modify bit 0 (invert manipulated variable)

and

MD 5011: ACTUAL_VALUE_CONFIG Modify

bit 0 (invert actual value)

and

MD 32110: ENC_FEEDBACK_POL

(actual value sign)

(adjust sign of actual velocity value)

Fig. 3-18 Start-up flow chart, definition of drive travel direction

Definition of drive

travel direction

(step 2)

Loading...

Loading...