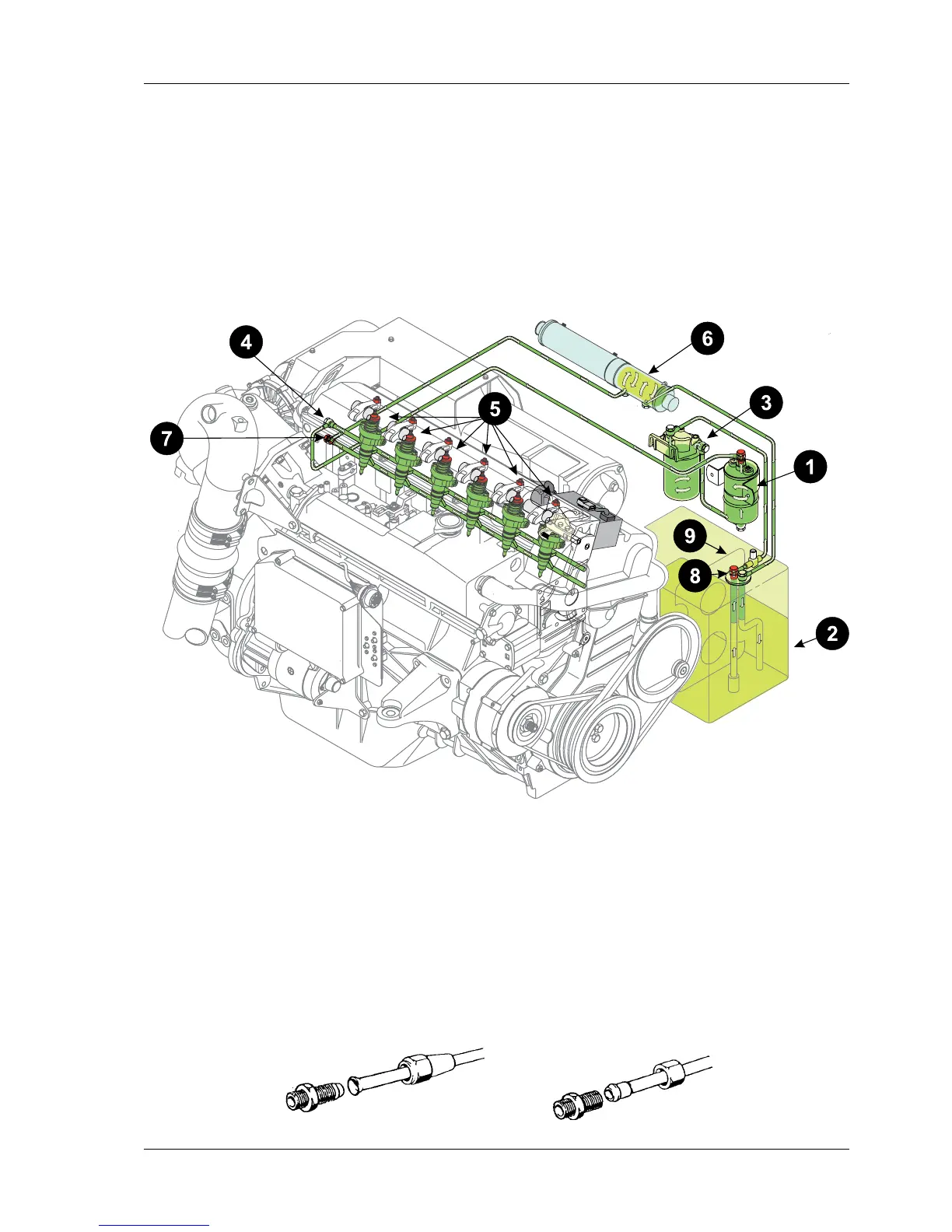

Functional Description

When the ignition switch is turned, an electric fuel pump 1 is put into operation and sucks fuel from

the fuel tank 2.Thisfuelisledviafuellter3 to the fuel pump. From the fuel pump, fuel is pumped

to the engine block 4 and the unit injectors 5. Excess fuel not injected by the unit injectors is led via

fuel cooler 6 back to the fuel tank.

The operating pressure is controlled by pressure valve 7 (1,8 - 2,5 bar at idle).

8 anti-siphon valve; 9bafes(dependingontanksize)

For fuel requirements, refer to chapter GENERAL

Specicationforfuelpipes

Minimum inside diameter: 8 mm

Recommended material: stainless steel or copper

NOTE: Min. inside diameter for hosepipes or PA-pipes is 10 mm.

Rateofow: > 240l/h +/-7 (in case of continuously operating pump)

Ifadditionalltersareinstalled,therequirementsof

higherowratesmusttobeconsidered.(lterdimension)

NOTE: In case of pipe connections, pay special attention to the

tightnessofthesuctionpipe(allttingsandlinebeforefuelpump)!

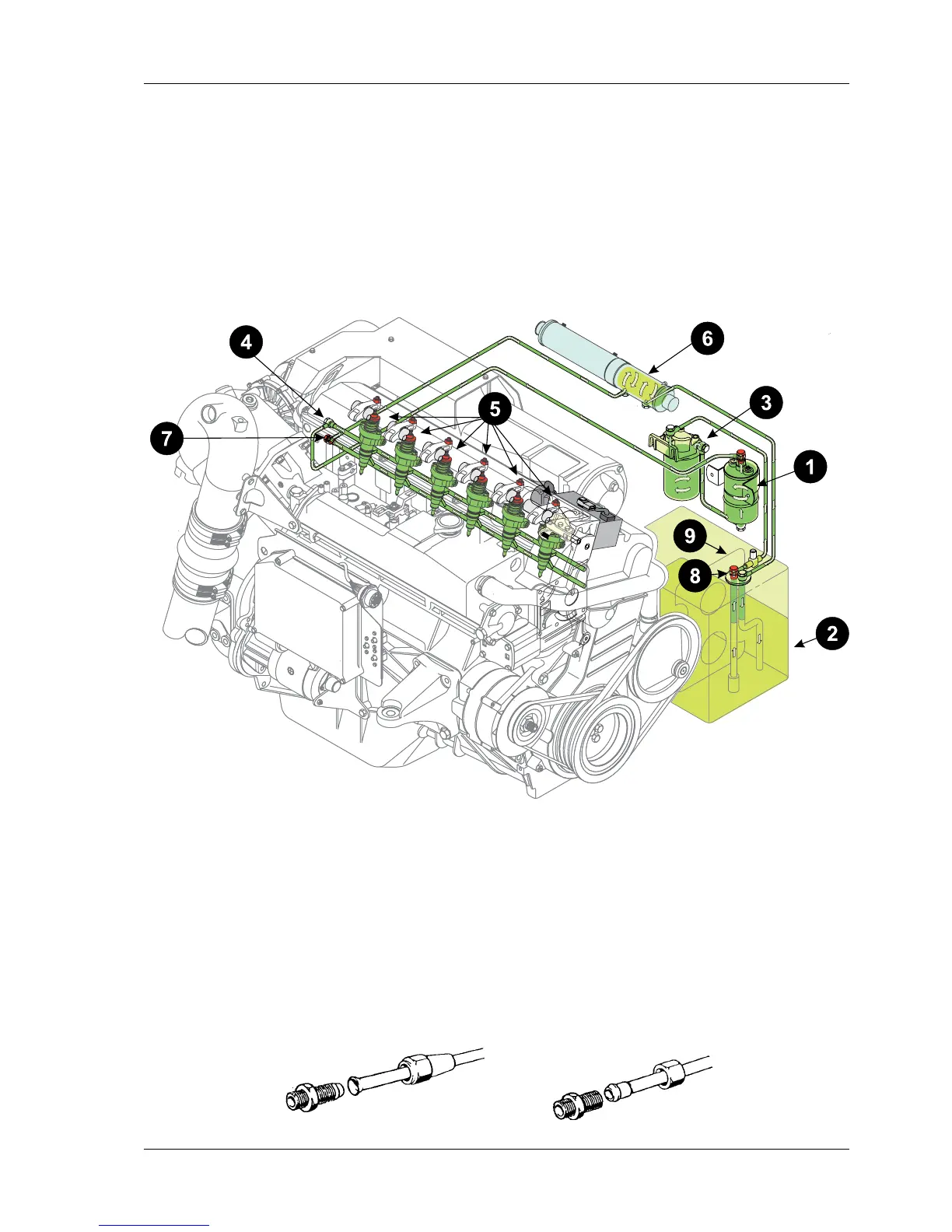

Types of pipe connections

03.00 ill. 2

03.00 ill. 1

Loading...

Loading...