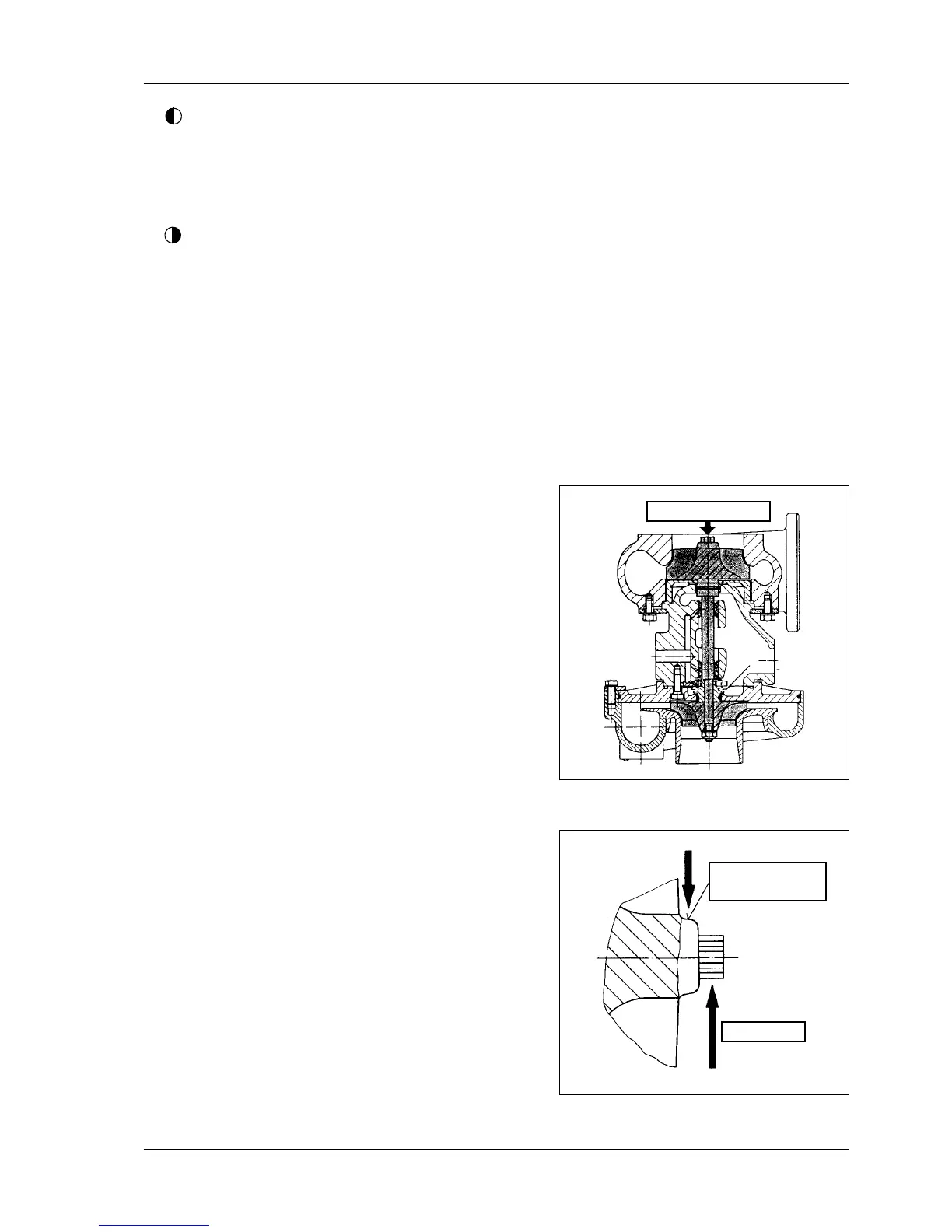

05.02 ill.1

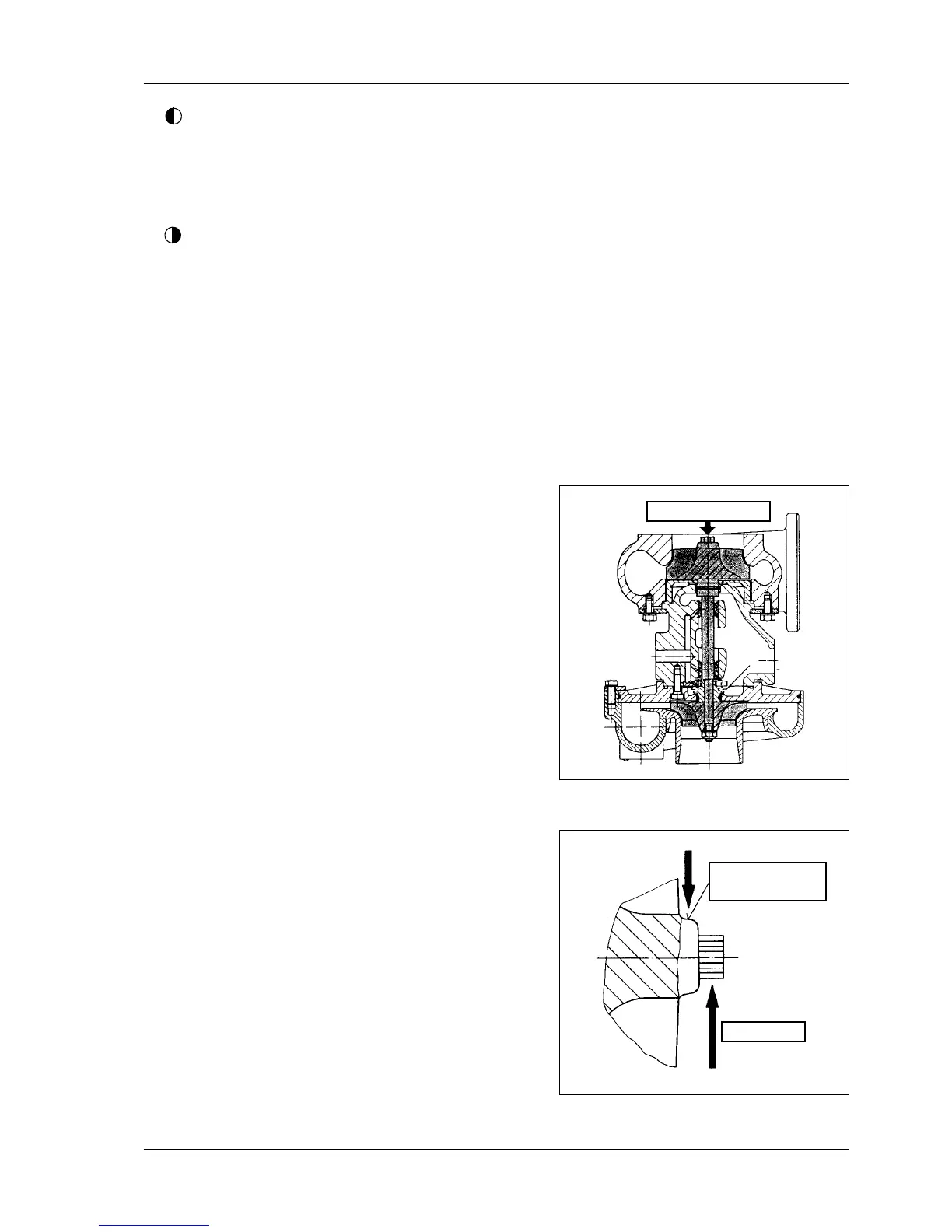

05.02 ill.2

03.05.02 Check bearing clearance

Measure end clearance:

1 Put test prod of dial gauge onto face of turbine wheel

hub.

2 Push cursor downwards and set dial gauge to "0".

3 Pushcursoragainstdialgaugeandnotedeection

of pointer.

permissibleendclearance:max.0.16mm+/-0,01

Measure radial clearance:

NOTE: Determination of radial clearance is

only required turbine-sided.

1 Put test prod of dial gauge onto center of retainer

cone of turbine wheel.

2 Pull turbine wheel hub upwards by means of spring

balance. Measuring strength 50 N.

3 Notedeectionofpointer.

4 Repeat measurement, by turning cursor by 90°.

Permissibleradialclearance:max.0.42mm+/-0,04

measuring point

measuring

strength

location point

of dial gauge

prod

For 4 cyl. engines only (item 1-2)

1 Tighten4hexagonnutsofturbochargerangewithatorqueof 25 Nm +/-2.

2 Tighten2screwsforxingtheangeofoilreturnpipewithatorqueof10 Nm +/-1.

Tighten hollow screw with 25 Nm +/-3.

For 6 cyl. engines only (item 3-6)

3 Tighten4hexagonnutsofturbochargerangebymeansoftorquewrenchNo.2300743/0andtree-

handled socket wrench No. 2300744/0 with a torque of 40 Nm +/-4.

4 Tighten2screwsforxingtheoilreturnpipeangewithatorqueof23 Nm +/-2.

Tighten hollow screw with 40 Nm +/-4.

5 Tighten hollow screw of vent pipe (cooling circuit) with a torque of 20 Nm +/-2.Maintainhorizontal

positionofbanjottingwhiletightninghollowscrew.

6 Fill closed cooling circuit, refer to 05.00.08

Loading...

Loading...