105MS 362, MS 362 C

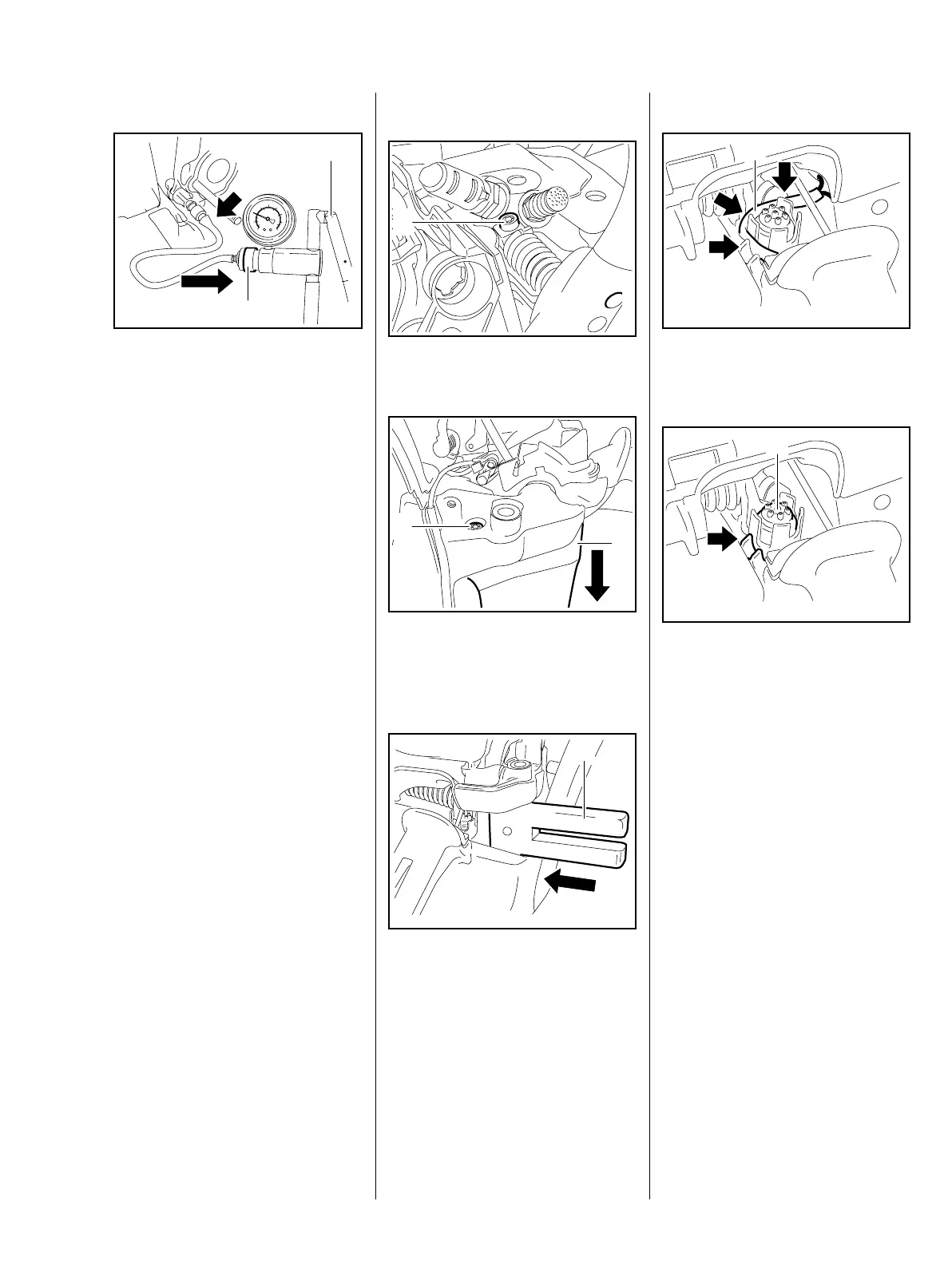

Pressure test

: Push the ring (1) to the right and

connect the pump (2)

0000 850 1300 to the nipple

(arrow)

– pressurize the fuel tank.

– Operate the pump until the

pressure gauge indicates a

pressure of 0.5 bar. If this

pressure remains constant for at

least 20 seconds, the tank,

including the tank vent, is airtight.

If the pressure drops, the leak

must be located and the faulty

part replaced.

– Always install a new fuel hose.

– Reassemble in the reverse

sequence.

0001RA408 TG

1

2

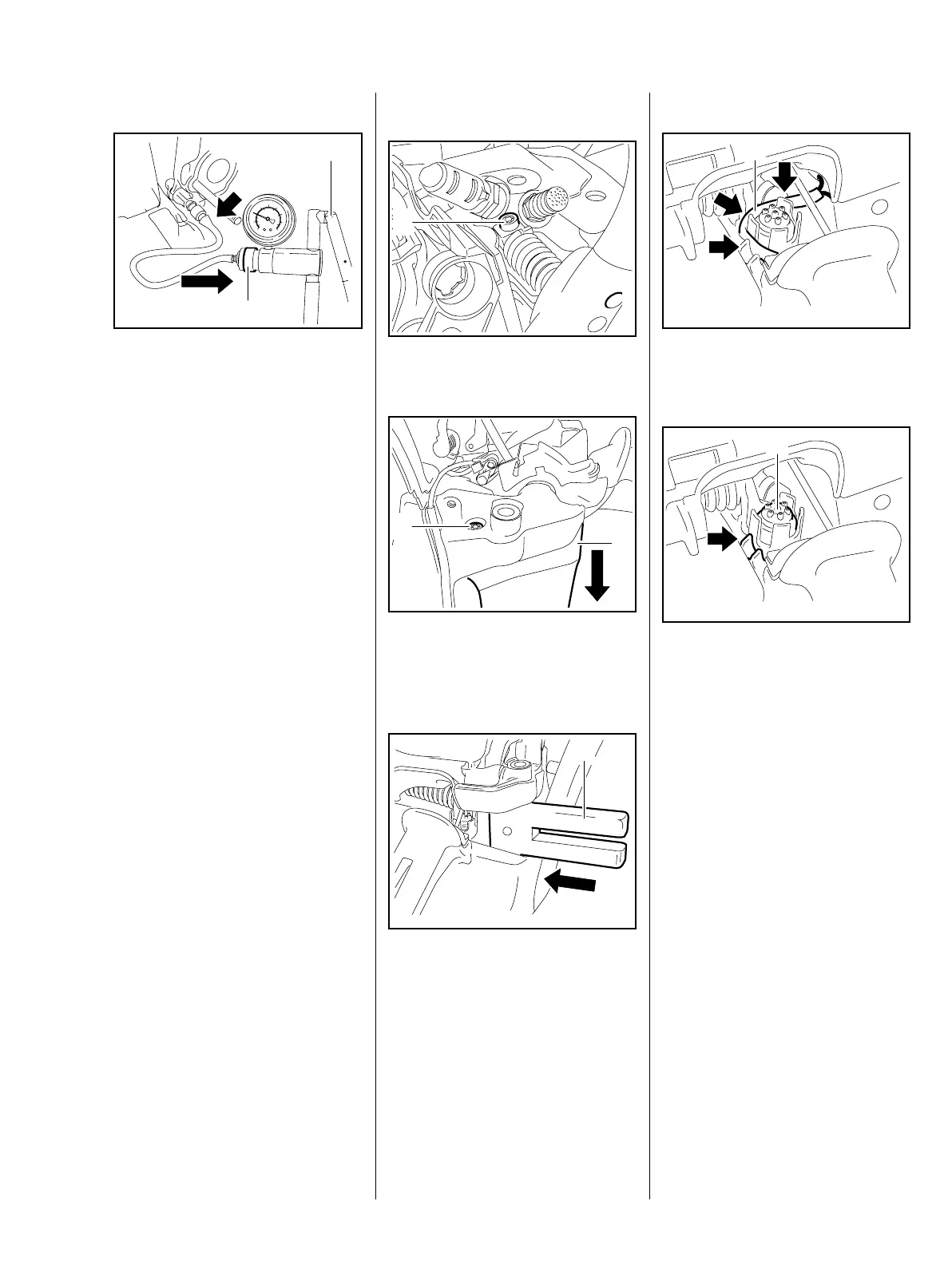

12.10.2 Removing and Installing

: Take out the screw (1).

: Take out the screw (1).

: Lower the tank housing (2).

: Slide the wooden assembly block

(1) between the crankcase and

tank housing.

0001RA508 TG

1

1

2

0001RA212 TG0001RA509 TG

1

Machines with Handle Heating

: Pull the wire with insulating tube

(1) out of the guides (arrows).

: Pry the tank vent (1) out of its

seat using the rib (arrow) for

leverage.

Always install a new tank vent.

– Coat sealing ring of new tank

vent with STIHL press fluid,

b 15

– Push home the tank vent by hand

until it snaps into position.

– Reassemble all other parts in the

reverse sequence.

1

0001RA409 TG

1

0001RA409 TG

Loading...

Loading...