39MS 362, MS 362 C

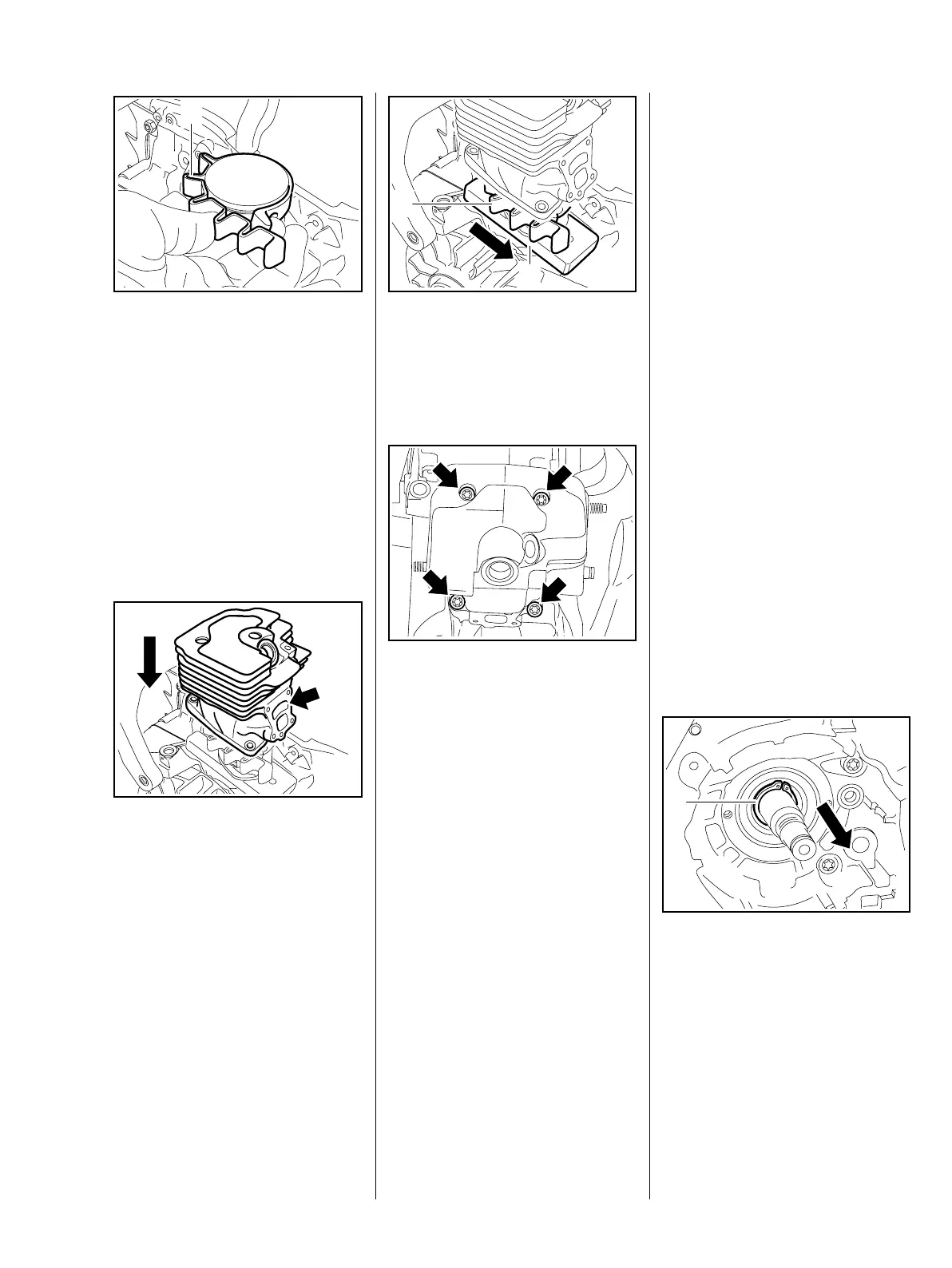

– Lubricate the piston, piston rings

and cylinder wall with oil, b 15

: Use the clamping strap (1)

0000 893 2600 to compress the

rings around the piston.

– Check correct installed position

of rings, b 6.8

Apply the clamping strap (1) so that

the piston rings do not project

beyond the cylinder wall.

: Align the cylinder so that the

intake port (arrow) points toward

the tank housing.

While sliding the cylinder over the

piston, hold the clamping strap

tightly around the piston so that the

rings do not project

– they might otherwise break.

: Slide the cylinder over the piston,

the clamping strap moves

downwards at the same time.

0001RA109 TG

1

0001RA110 TG

: Remove the clamping strap (1)

and wooden assembly block (2).

Make sure the cylinder gasket is

properly seated.

– Push the cylinder fully home.

: Insert the screws (arrows) to hold

the cylinder and gasket in

position..

– Tighten down the screws through

the holes (arrows) in the cylinder

in a crosswise pattern.

– Tightening torques, b 2.5

– Reassemble all other parts in the

reverse sequence.

0001RA111 TG

1

2

0001RA102 TG

6.6 Crankshaft

– Remove the brake band, b 5.2

– Remove the oil pump, b 11.3

– Remove the brake lever, b 5.3

QuickStop Super, b 5.4

– Drain the fuel and oil tanks,

b 1.2

– Remove the tank housing,

b 12.11.3

– Remove the flywheel, b 7.6

– Machines with handle heating:

Remove the generator, b 13.7

– Remove the cylinder, b 6.5

– Remove the piston, b 6.7

Always install new bearings and oil

seals after removing the crankshaft,

b 6.6.1 and b 6.3.

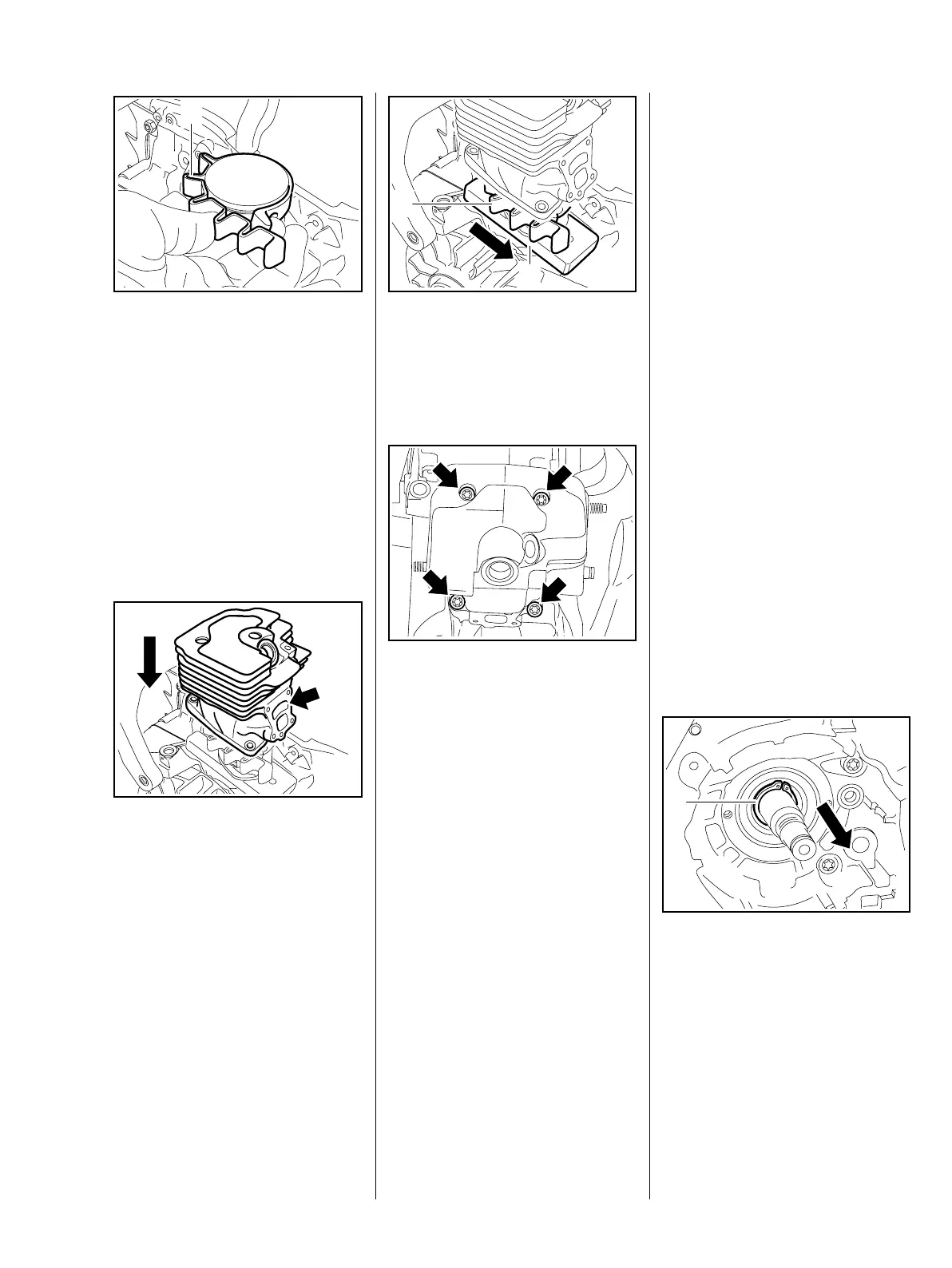

Clutch side of crankcase

: Remove the E-clip (1).

0001RA495 TG

1

Loading...

Loading...