45MS 362, MS 362 C

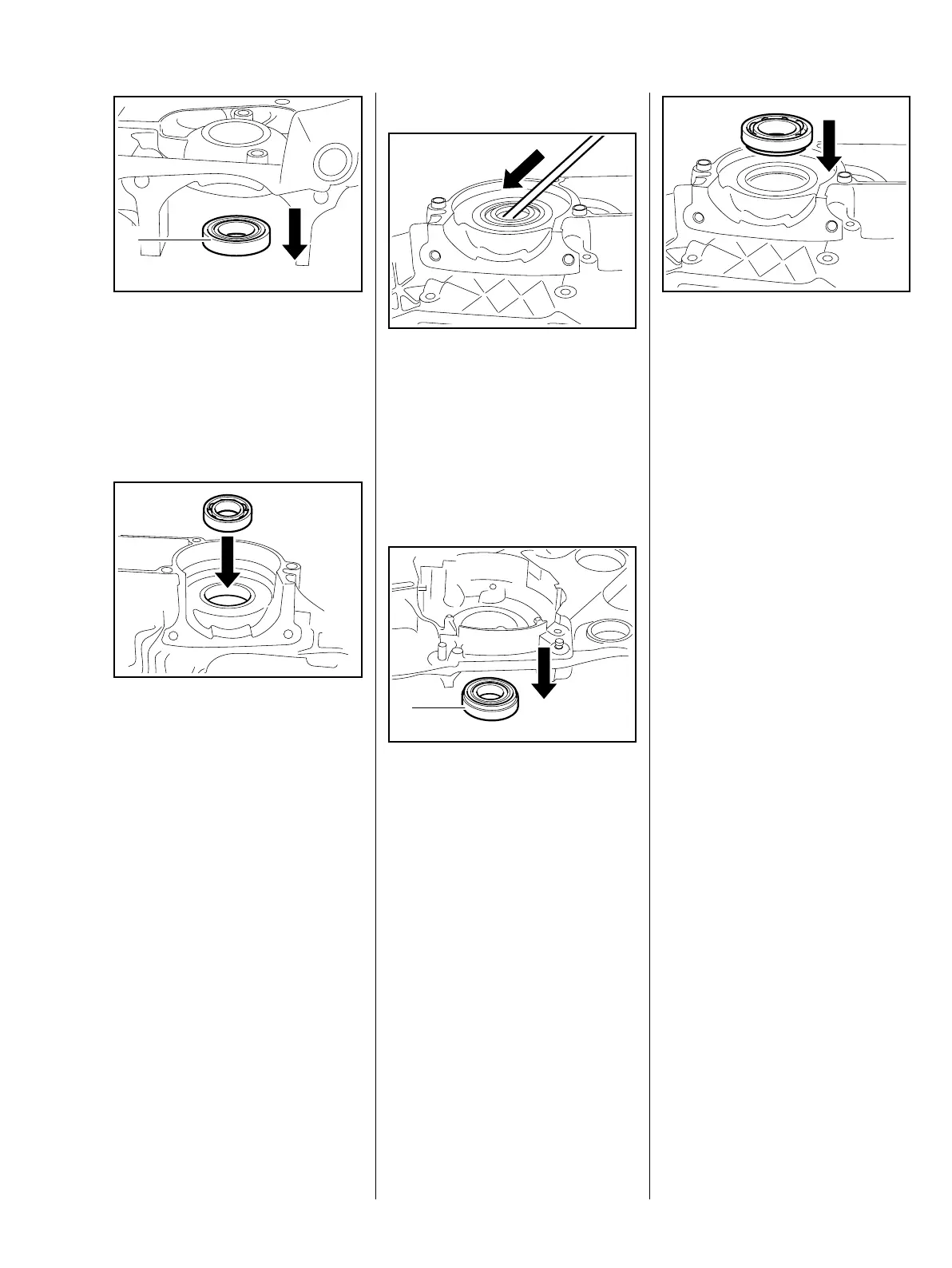

– Heat area of bearing seat to

approx. 150°C (300°F).

The bearing (1) drops out as soon

as this temperature is reached.

Installing

– Heat area of bearing seat to

approx. 150°C (300°F).

– Position the ball bearing so that

its open side (balls visible) faces

the inside of the crankcase.

: Push the ball bearing home as far

as stop.

This operation must be carried out

quickly because the bearing

absorbs heat and begins to expand.

– Check that the bearing is properly

seated. If necessary, use

press arbor 1127 893 2400 to

press the bearing fully home.

0001RA133 TG

1

0001RA134 TG

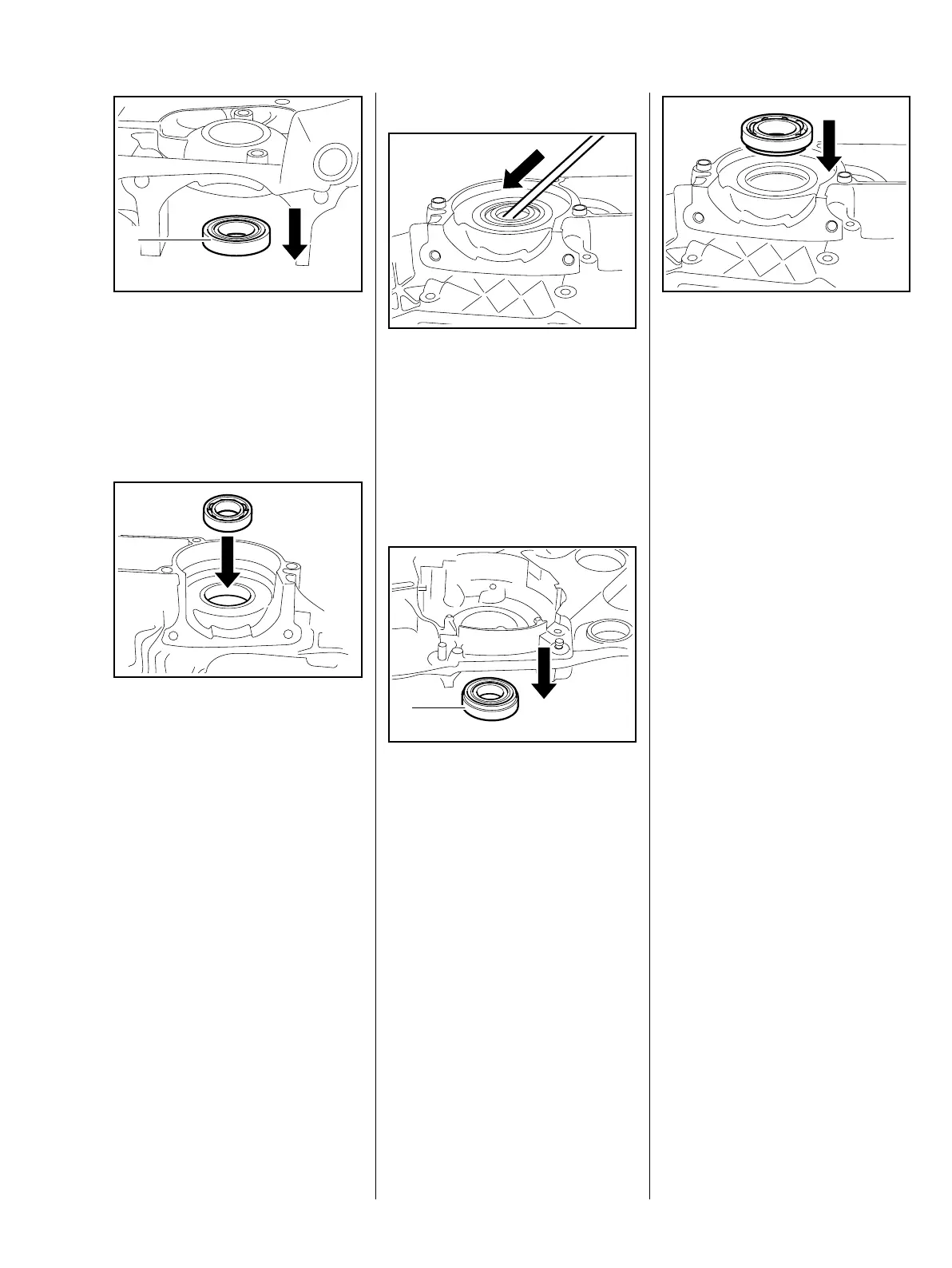

Clutch side of crankcase

: Use a suitable punch to carefully

drive out the oil seal.

– Check and clean the crankcase

or replace if necessary.

– If this half of the crankcase is in

order, install a new ball bearing.

– Heat area of bearing seat to

approx. 150°C (300°F).

The bearing (1) drops out as soon

as this temperature is reached.

Installing

As the bearing seat in the clutch half

of the crankcase has no locating

face, the oil pump must be installed

first

– the oil pump serves as a locating

face.

– Install the oil pump, b 11.3

0001RA135 TG0001RA137 TG

1

– Heat area of bearing seat to

approx. 150°C (300°F).

– Position the ball bearing so that

the centering ring points toward

the oil pump.

: Push the ball bearing home as far

as stop (oil pump).

This operation must be carried out

quickly because the bearing

absorbs heat and begins to expand.

– Check that the bearing is properly

seated. If necessary, use

press arbor 1127 893 7200 to

press home the bearing until it

butts against the snap ring.

– Remove the oil pump, b 11.3

– Install the crankshaft, b 6.6

– Install the oil seals,

b 6.3

– Reassemble all other parts in the

reverse sequence.

– Tightening torques, b 2.5

0001RA138 TG

Loading...

Loading...