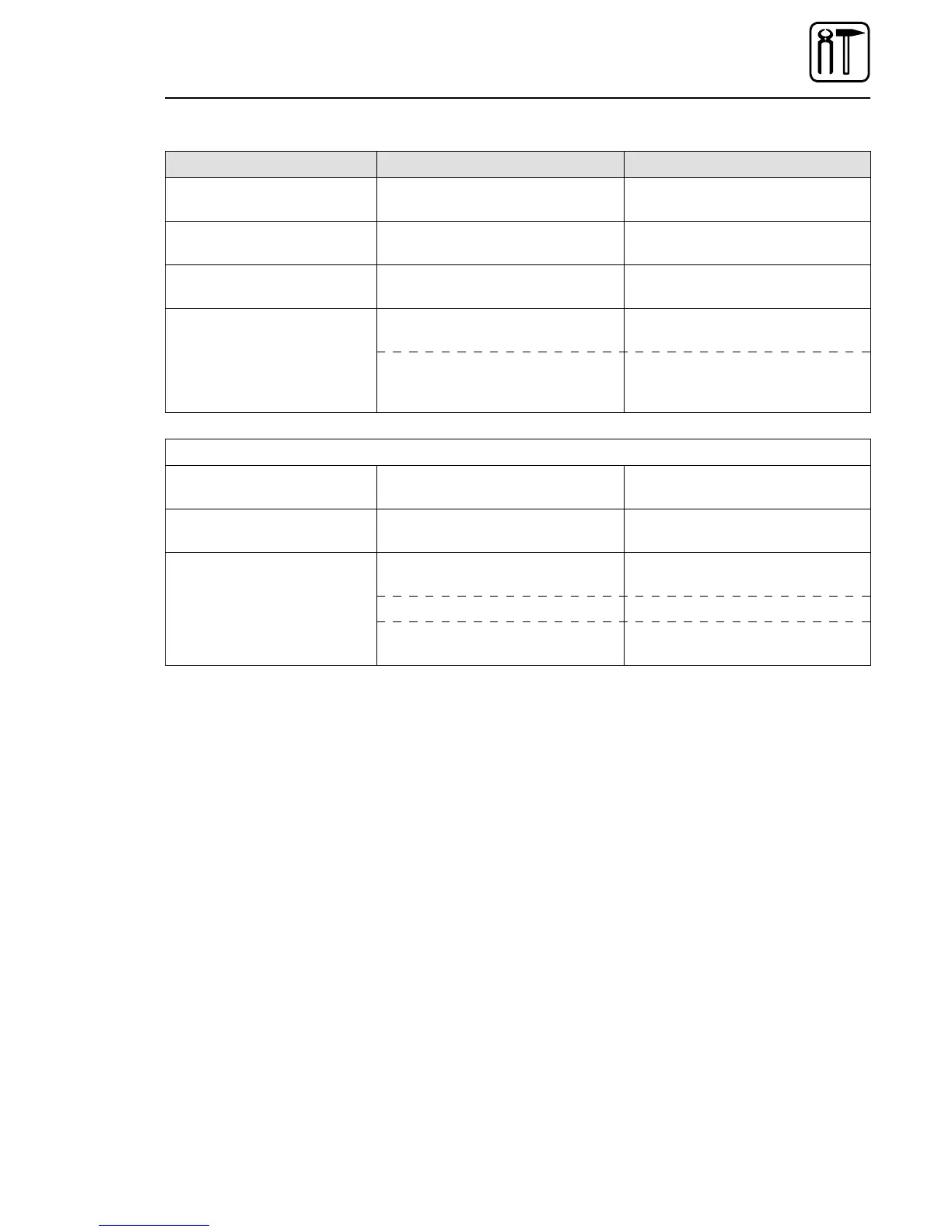

Failure Reason Remedy

Cuts are not cut through pro-

perly

Knife tip is too short due to frequent

regrinding

Replace knife

Knife sticks in

channel

Bone fragments in product Release brake and remedy the

failure cf. chapter 12.8

Poor cutting results Knife is blunt Regrind or replace knife

(re cf. chapter 15.2 or 9.2)

Pneumatic cutting material hol-

der does not grip automatically

Compressed air supply of the

machine out of order

Check compressed air supply

( re cf. chapte6.4.)

Plug connector of compressed air

supply not reconnected after

cleaning

Insert plug connector

(Refer to page 68)

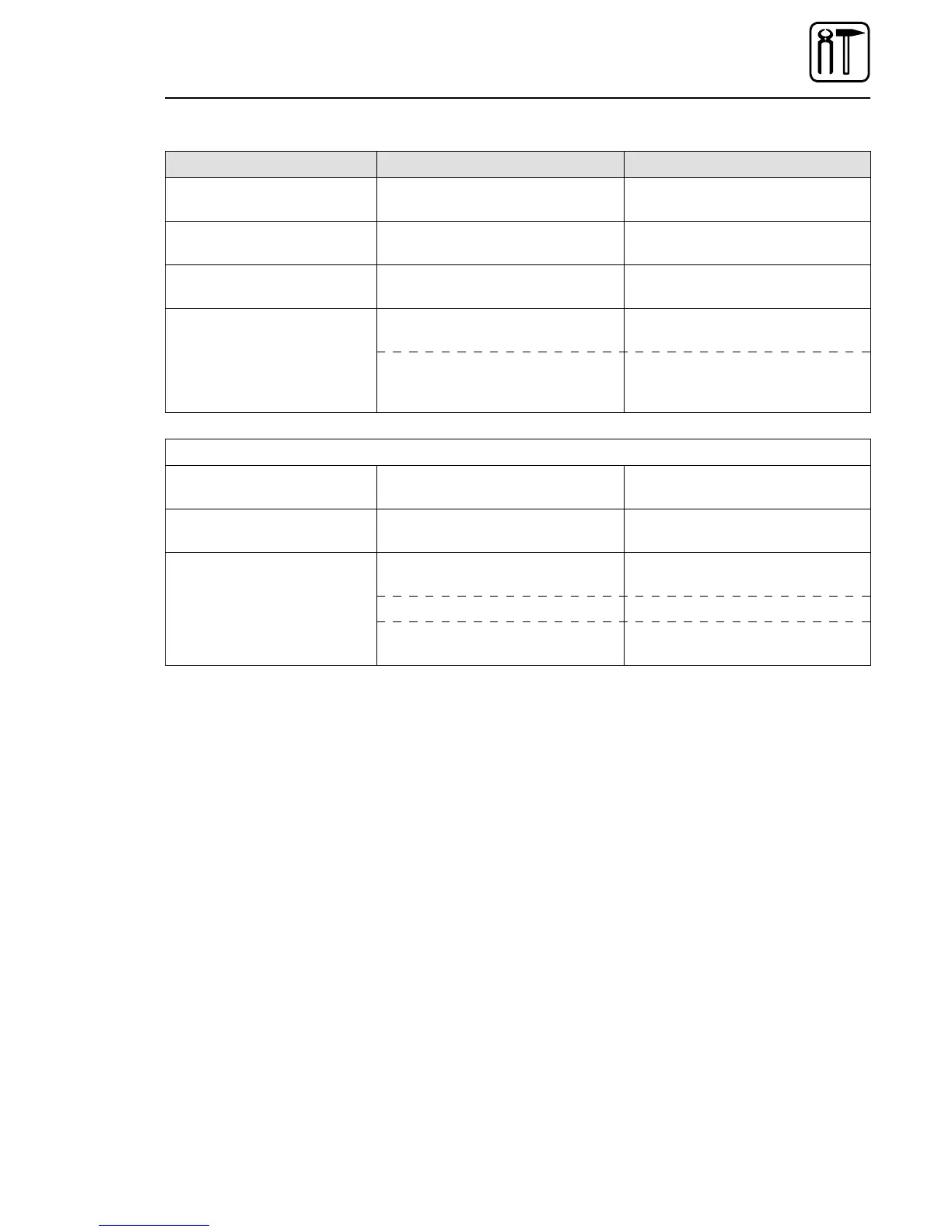

Only for machines with conveyor:

Conveyor belt runs lopsidedly belt is not tensioned equally readjust the tensioning screws cf.

chapter 15.6

Conveyor belt slips through belt has not been tensioned enough tighten tensioning screws

cf. chapter 15.6

Conveyor belt does not run conveyor speed control system is

set to position »O«

change setting Also possible with

the machine running

Plug not inserted in conveyor Insert plug cf. chapter 7.2

Conveyor drive motor overloaded Let it cool down (restarting is carried

out automatically)

Fault finding

02/2005 123842-GB Page 79

Loading...

Loading...