17. Repair instructions

The work described below may only be carried out by the

service department or especially trained staff.

Note:When carrying out any work on the electrical systems, always

observe the information in the relevant circuit diagram.

Do not hesitate to telephone our customer service department with any

questions you may have. (

✆

02685/944-0)

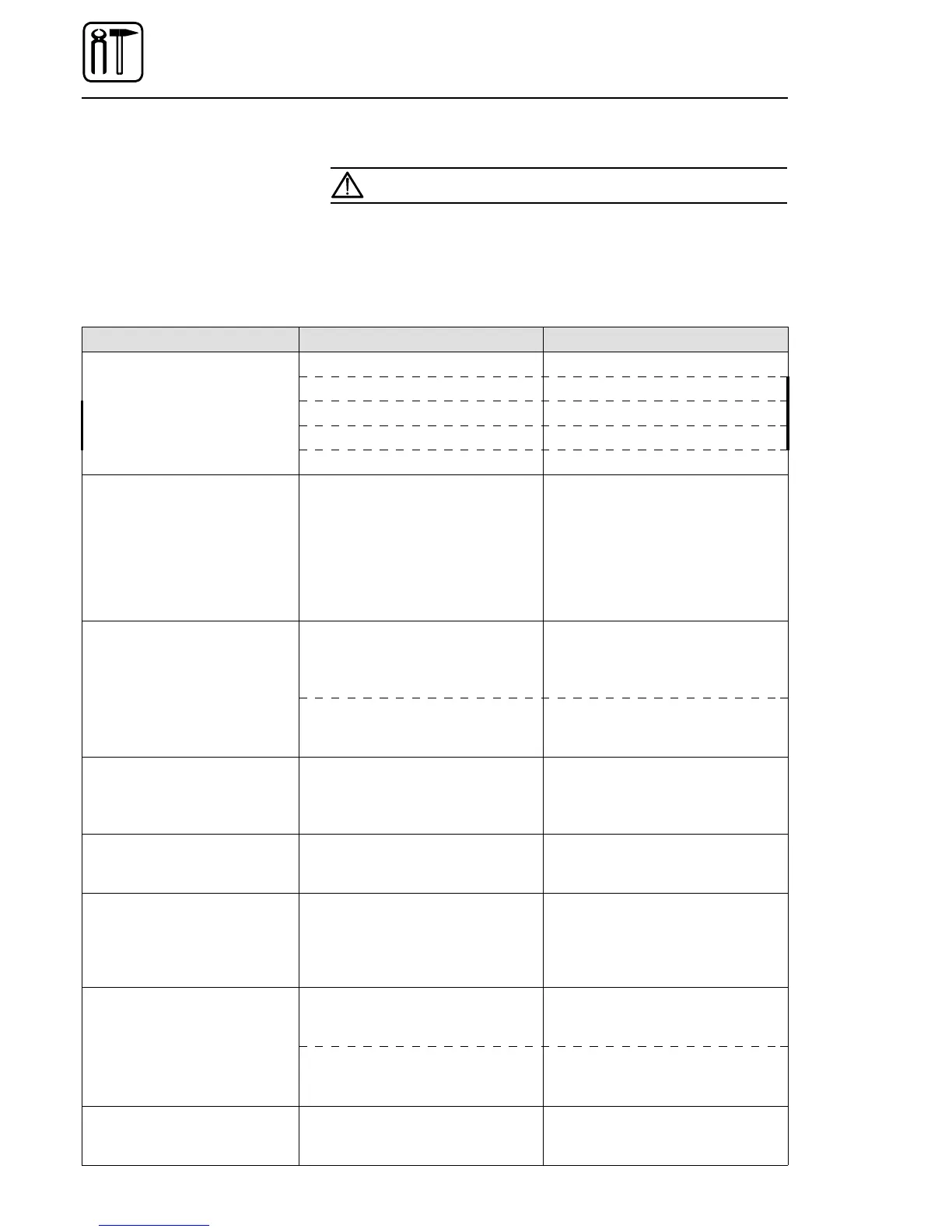

Failure Reason Remedy

No LCD display Input fuse in feed cable defective Replace

Fuse F1, F2, F3, F4 or F5 defective Replace

Display defective Replace

Control unit N 1 defective Replace

Power unit T1 defective Replace

Display shows:

Emergency off

— Knife box

– Infeed chamber

– Removal

– Feed cover

Appropriate cover is open

Are solenoids of S1, S2, S3 and S4

active ?

Motor protection switches S1, S2,

S3, S4 have been misaligned or are

defective

close

Check, and replace the solenoid, if

necessary

Adjust, respectively replace

Display shows:

Failure

– Knife drive

– Feed drive

Motor overheated during operation Let it cool down

(restarting is carried out

automatically)

Feed drive overheated during

operation

Let it cool down, then switch main

switch off and on again

After pressing the Start push-

button, the product feed holder

does not move forward (no mes-

sage on display)

Feed motor is defective

Synchronous belt has torn

Repair or replace

Replace

Product feed holder stops at

front; knife continues running

Proximity switch S15 is defective or

misaligned

Replace or adjust

Product feed holder has moved

backward; the feed motor conti-

nues operating (friction clutch

causes loud banging)

Proximity switch S6 is defective or

misaligned

Replace or adjust

’Open and close loading door’

message cannot be removed

after several attempts

CPU A1 defective Replace

May be replaced by same make /

type only !

Contactor K1M, K1S, K2, K3, K4,

K5 or K6 is defective

Replace

May be replaced by same make /

type only !

Cutting process starts immedi-

ately without pushing the pro-

duct forward first

Emitter S16A or reflector S16B of

the light barrier is dirty or defective

Clean or replace

Repair instructions

Page 80 02/2005 123842-GB

Loading...

Loading...