9. Setting up operations

9.1. Product feed holder

Two different cutting material holders are used with the TREIF PUMA-CE

’electronic’

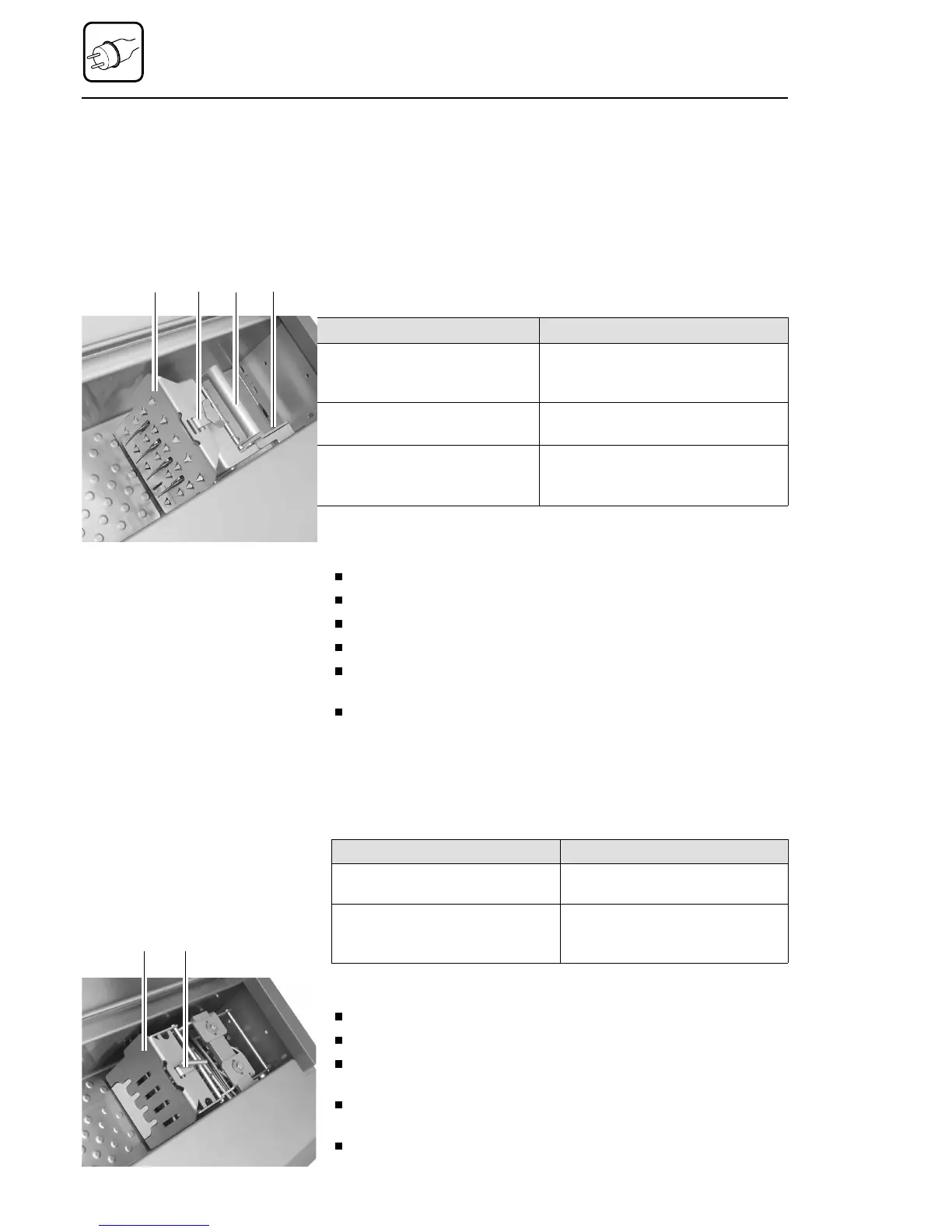

9.1.1 Manual cutting material retainer

The cutting material holder can be adjusted to suit different cutting

materials via transfer of the infeed plate.

Feed plate position Cutting process

Front

(e.g. fresh meat)

Clamping lever remains open during

cutting

(minimum scrap).

Centre

(standard)

Product must be secured for cutting

by raising the clamping lever.

Rear

(Products with inconsistently sha-

ped ends)

Product must be secured for cutting

by raising the clamping lever

(somewhat more scrap).

Adjusting the feed plate:

Raise locking catch 4 and open clamping lever 3.

Loosen locking handle and swivel clamp 2 to the side.

Lift out feed plate 1 from retainer.

Install feed plate with base in desired groove, i.e.

» front/centre/rear «

.

Swivel clamp 2 onto feed plate and install in appropriate groove in

head of feed plate.

Secure clamp with locking handle.

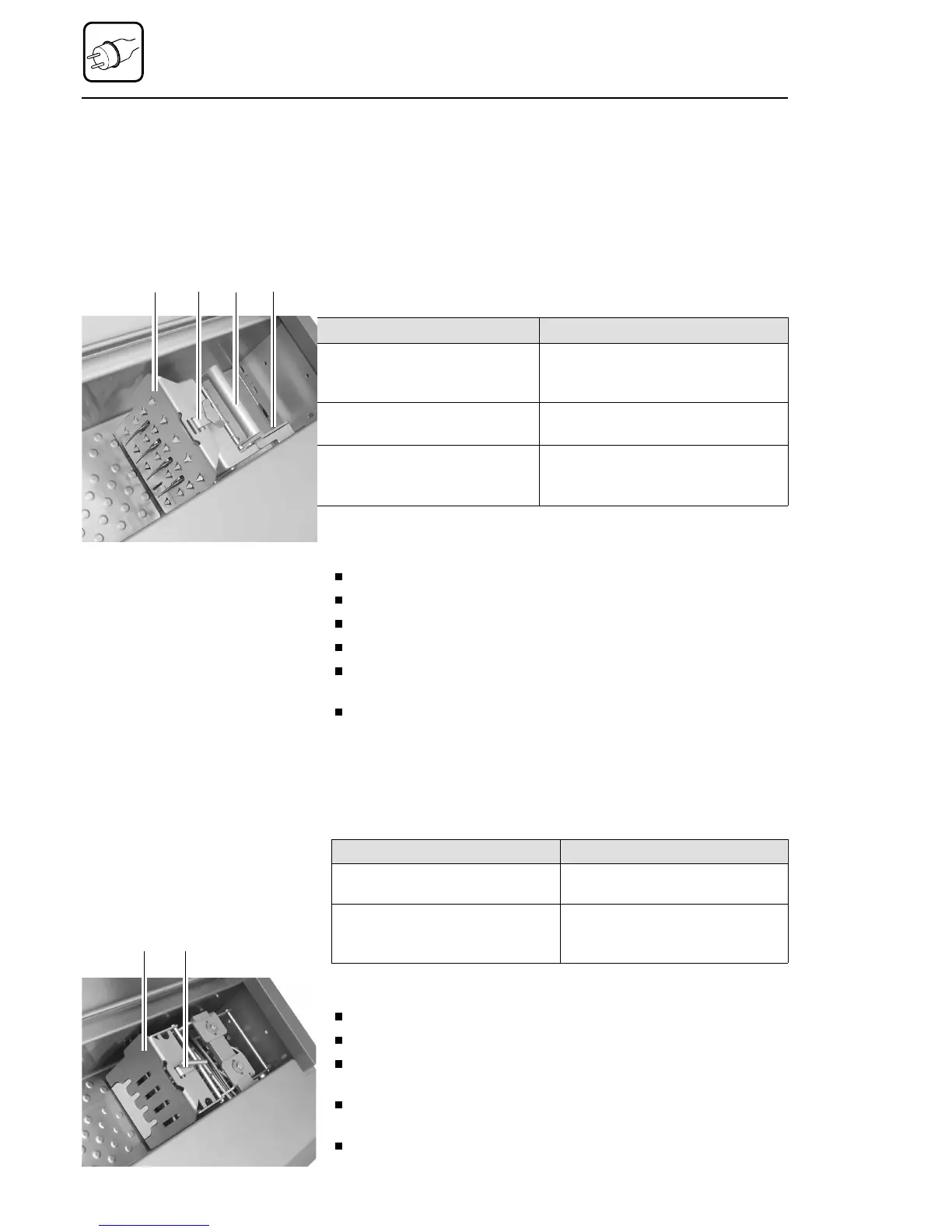

9.1.2 Pneumatic product holder

The pneumatic cutting material holder can also be adjusted to suit

different cutting materials via transfer of the infeed plate.

Feed plate position Cutting material

Assemble at the front e.g. fresh meat

(minimum residual piece)

Assemble at the rear Cutting materials with misshapen

end pieces (residual piece

remains slightly larger)

Convert infeed plate:

Loosen toggle handle and swivel aside holding claw 2 .

Lift infeed plate 1 upward out of the support.

Hang foot of the infeed plate into >>front/centre/back<< with the

desired notch.

Swivel holding claw 2 across the infeed plate and hang into the

corresponding notch at the head of the infeed plate.

2

Secure holding claw via toggle handle.

1 2 3 4

1 2

Setting up operations

Page 28 02/2005 123842-GB

Loading...

Loading...