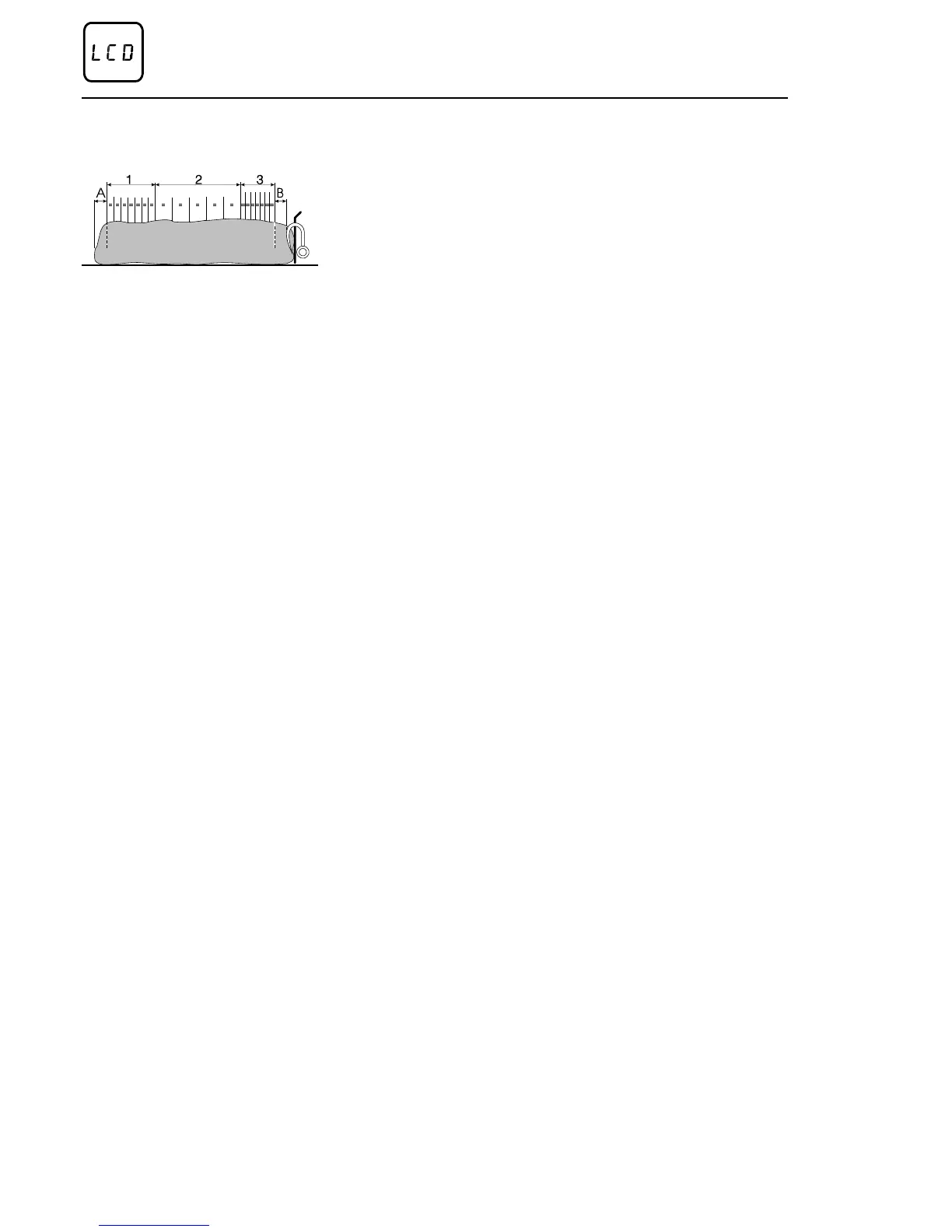

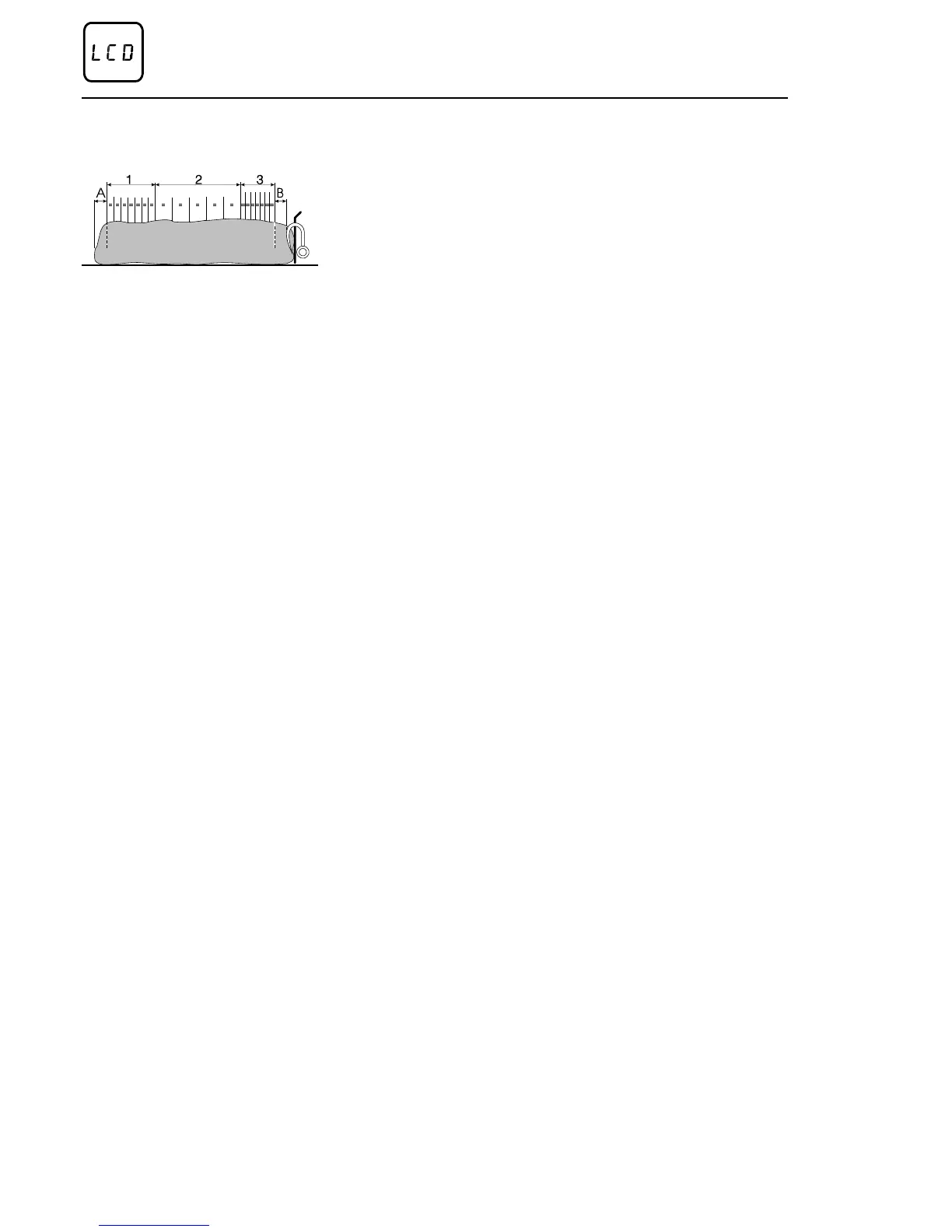

11.9. Cutting zones - definition

When a single knife is used, the product can be divided up in up to ten

different cutting zones (example: 3). The remaining centre piece between

first cut [A] and the remaining piece [B] is divided up proportionately“ in

zone lengths. These zone lengths can be set to different cutting thick-

nesses.

Alternative:

If the Number of slices type of optimisation is used, the cutting zone will

be divided up into the given number of slices.

Function after start:

– The raw material is first pushed to the knife slot.

– The control calculates the length of the product rack to be cut between

the first cut [A] entered and the remaining piece [B].

– The centre piece calculated is cut up according to the cutting thickness

set.

The thickness of the slices is increased / decreased (within the possibi-

lities of the cutting thickness tolerance set) in such a way that the last cut

corresponds exactly to the remaining piece [B] set (which can be “0 mm”

as well).

Tolerance in cutting thickness:

The tolerance in cutting thickness is used to determine by how many per

cent the slice thickness may be increased or decreased for remaining

piece processing.

Example: cutting thickness: 30 mm

tolerance in cutting thickness: 10 per cent

= the slices may vary between 27 and 33 mm in thickness.

Switching the function off:

If the tolerance in cutting thickness is set to ’0 %’, the product will be cut

as set for the cutting thickness.

The remaining piece processing function is thus switched off.

Method of operation of the control

Page 38 02/2005 123842-GB

Loading...

Loading...