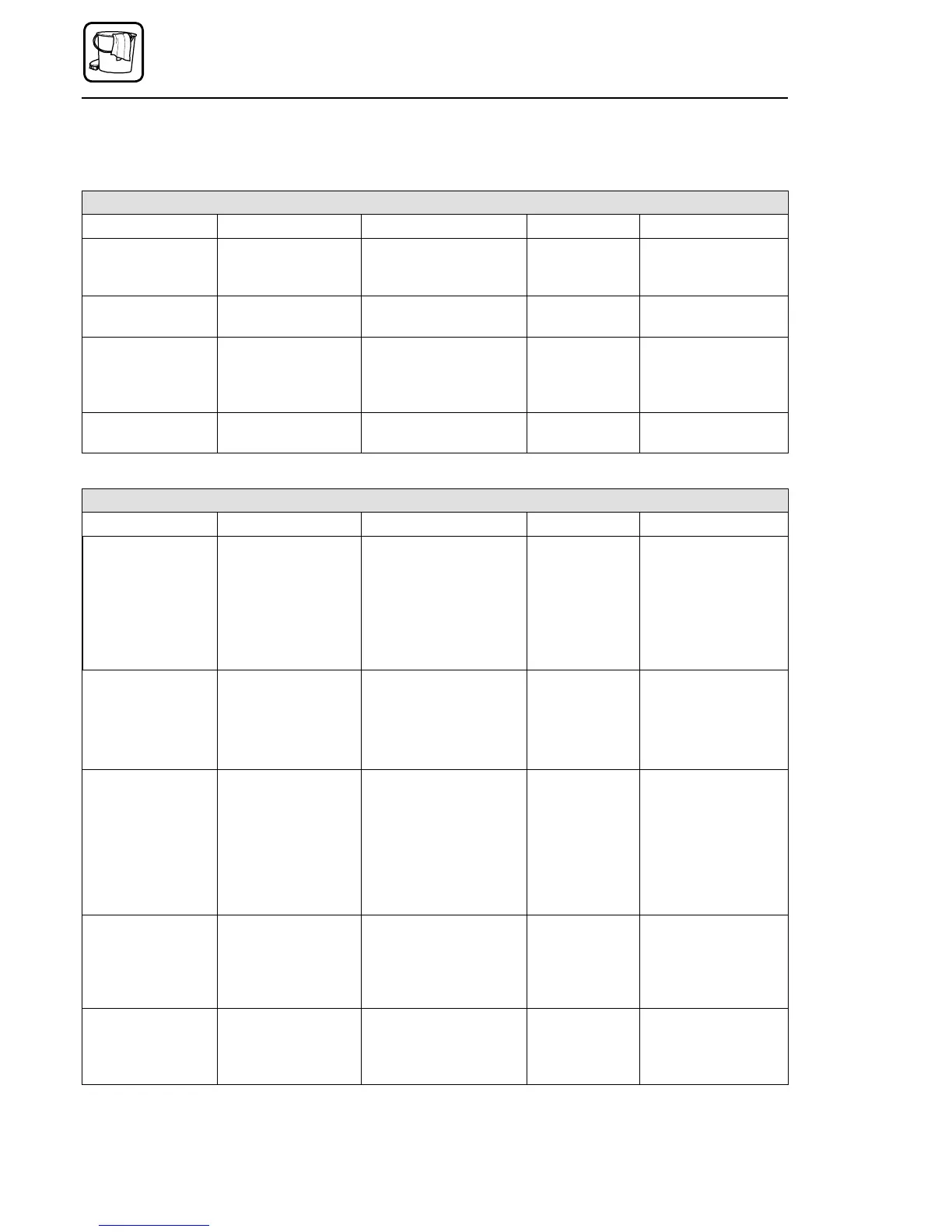

14.3. Cleaning and disinfection plan

Pre-Cleaning (Start after finishing production)

Working steps Detergent Process Appliances Notes

Coarse cleaning,

(removal of

product rests)

– – – manual,

mechanical

plastic spatula,

plastic scraper

– – –

Dismantling of

small parts

– – – – – – ring spanner

supplied

Rinse thoroughly potable

water

low pressure < 30 bar

temperature50° C

(according to fat

softening point)

low-pressure

cleaning device,

hose

From top to bottom.

Do not forget small

parts !

Check for visual

cleanness

– – – visual – – – – – –

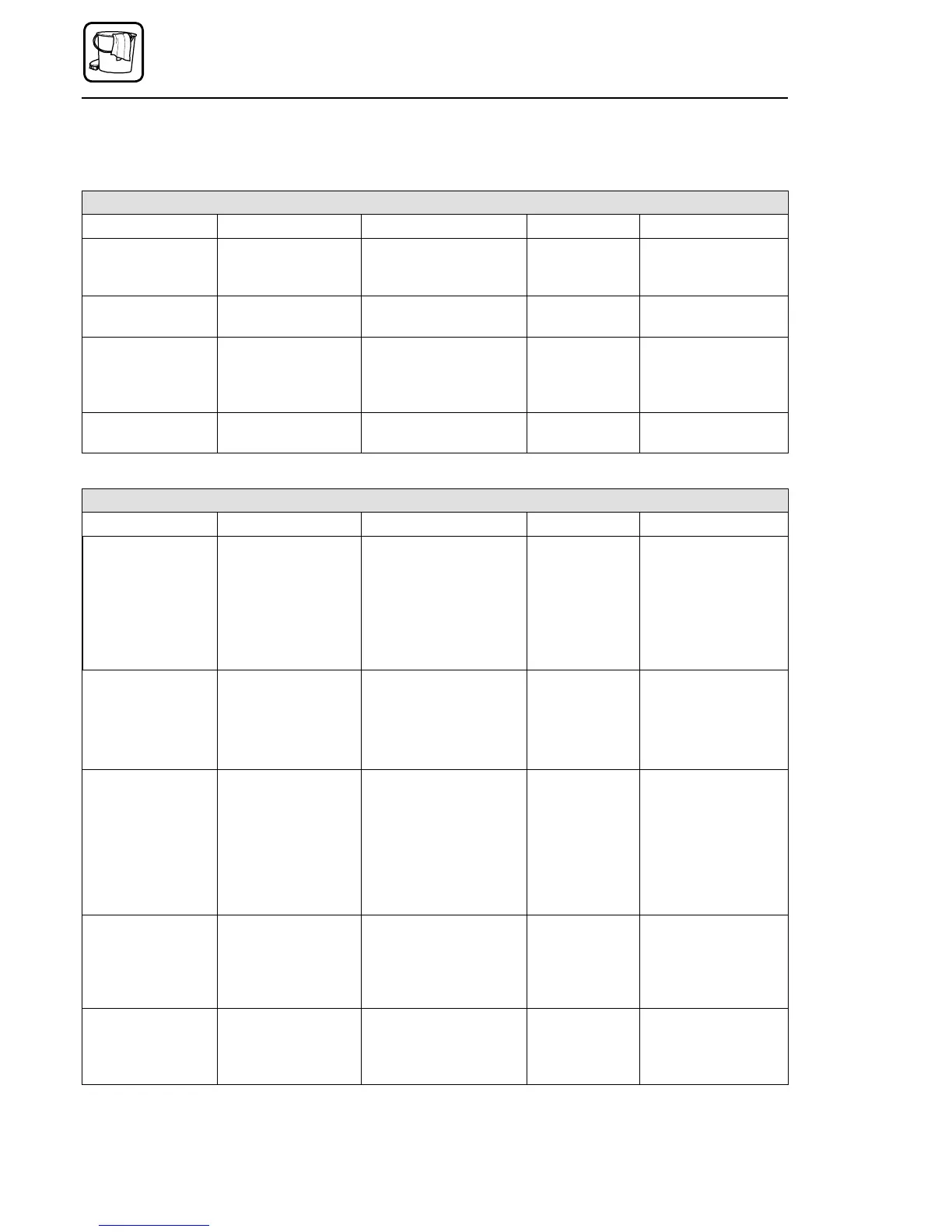

Cleaning (alkaline or acid)

Working steps Detergent Process Appliances Notes

Cleaning small

parts

Ecolab:

1-2% *

P3-steril

use brush to manually

clean in the tub

low pressure < 30 bar

action time:

approx. 15-30 min

temperature 40° C

low-pressure

foaming device,

manual

spraying device,

brush, tub

Spray small parts

from

bottom to top

Alkaline

cleaning

(daily)

Ecolab:

2-5% *

P3-topax 19 or

Topactive 200

lather,

low pressure < 30 bar

action time:

approx. 15 min

low-pressure

foaming

device

Foam the machine

from bottom to top

Acid cleaning

(To be employed

approx. once a

week instead of

alkaline cleaning, if

necessary, to

remove any

furring.)

Ecolab:

2-5% *

P3-topax 56

lather

low pressure < 30 bar

action time:

approx. 15 min

low-pressure

foaming

device

Foam the machine

from bottom to top

Rinsing potable

water

low pressure < 30 bar

temperature 50°C

low-pressure

cleaning device,

hose

Rinse the entire

machine from top to

bottom; rinse small

parts on a grate or

table.

Check for visual

cleanness

– – – visual – – – Check product-

touching and

adjacent areas

especially.

Cleaning

Page 66 02/2005 123842-GB

Loading...

Loading...