50-22 Operation D7x11 Series II Navigator Directional Drill

WHILE DRILLING OUT

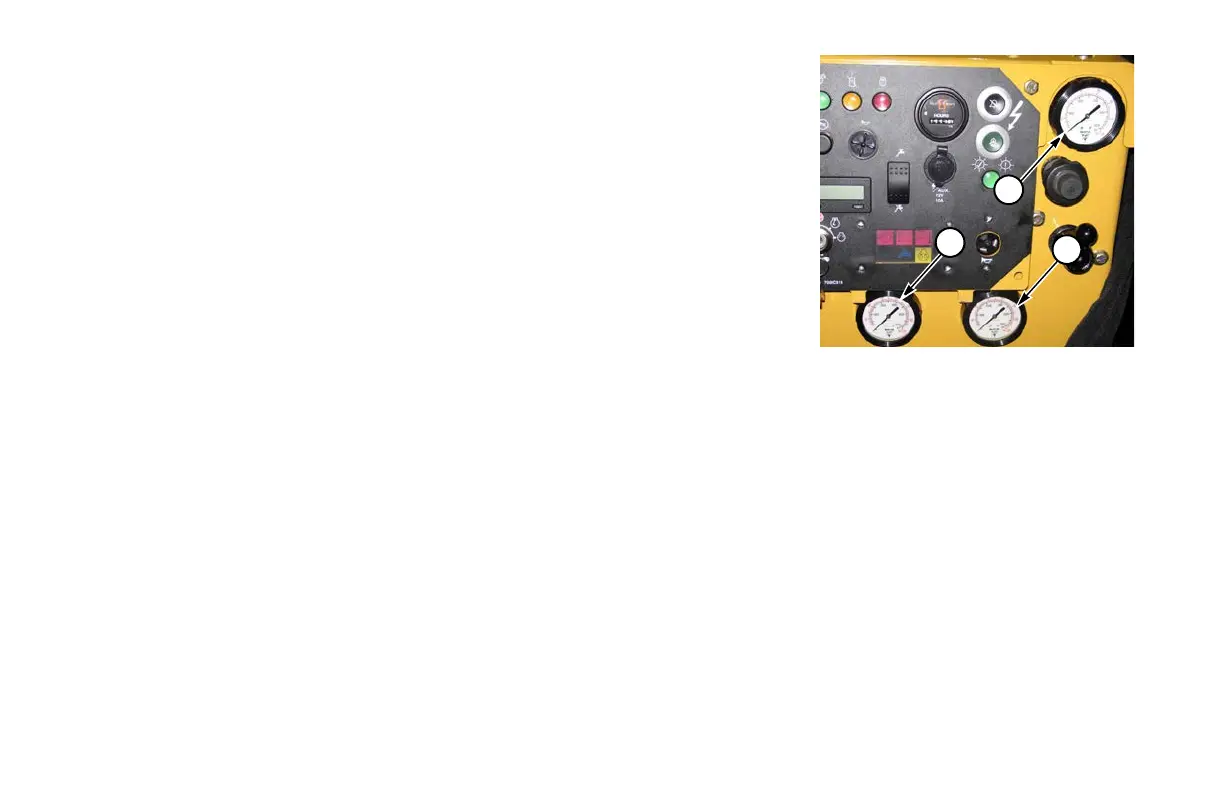

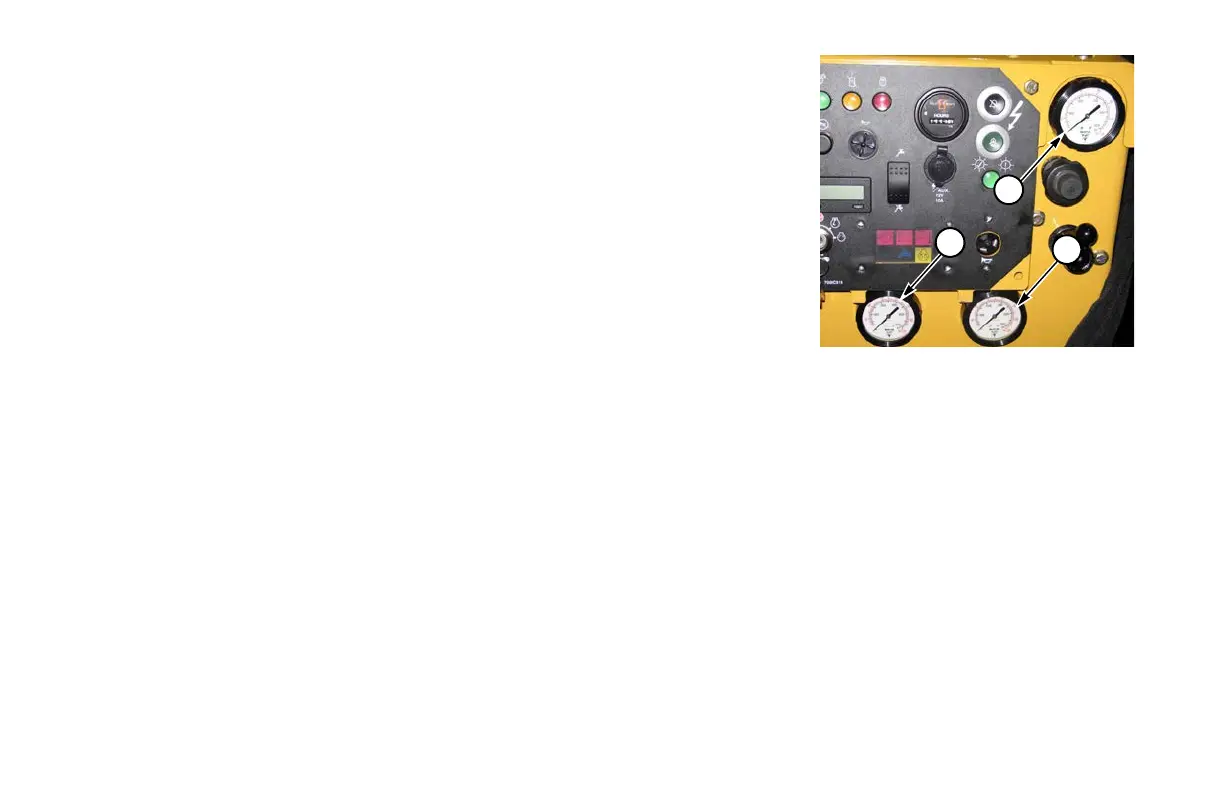

Gauges - Monitor

Monitor gauges during drilling operation to ensure a good pilot bore. Watching the gauges

will help establish a baseline for rotation and thrust/pullback pressures. Generally, the

operator should try to keep rotation and thrust/pullback pressures as low as possible

throughout the bore.

Rotation Pressure (1)–Rotation pressure will naturally rise as the bore progresses, due

to friction on the increasing length of the drill string. But if rotation pressure rises

substantially, even when not attempting to make forward progress, it could be a sign that

soil is taking on water and swelling around the drill string. If this happens, it may be

necessary to reevaluate the drilling fluid additives, increase flows, and redrill the pilot

bore.

Thrust/Pullback Pressure (2)–Thrust/pullback pressure can be affected by product size and weight, bore

path lubrication, soil conditions, and bends in the bore. If the pullback gauge hits the maximum pressure,

maximum pullback force is being exerted, and the bore will be unable to continue.

NOTE: The Thrust/Pullback Pressure Gauge also indicates vise pressure.

Drilling Fluid Pressure (3)–The drilling fluid pressure gauge is best used as an indicator that flow is

occurring. Pressure can vary based on flow rates and nozzle sizes used in the tooling. A maximum indication on

the drilling fluid pressure gauge could be an indicator that flow has become restricted.

Obstructions - Investigate

Closely monitor the drilling rate and investigate any obstruction to determine if it might be hazardous. Check to

ensure tool is not in contact with a gas line, water line, electrical line, or some other underground obstruction

that can be damaged or result in personal injury.

1

2

3

Loading...

Loading...