30-24 Overview D7x11 Series II Navigator Directional Drill

Reamer - Connect with Threaded Connection

Step 1: Ensure drilling machine has been locked out.

Step 2: Ensure components are clean.

Step 3: Lubricate threaded end of reamer.

Step 4: Align reamer with drill string and manually turn reamer by hand until reamer is completely threaded

onto drill string.

Step 5: Remove reamer carrier.

Step 6: Use Portable Breakout system to tighten connection. Refer to the Supplemental Operations section,

“Portable Breakout System,” page 55-4, for procedures. Refer to following chart for makeup torque.

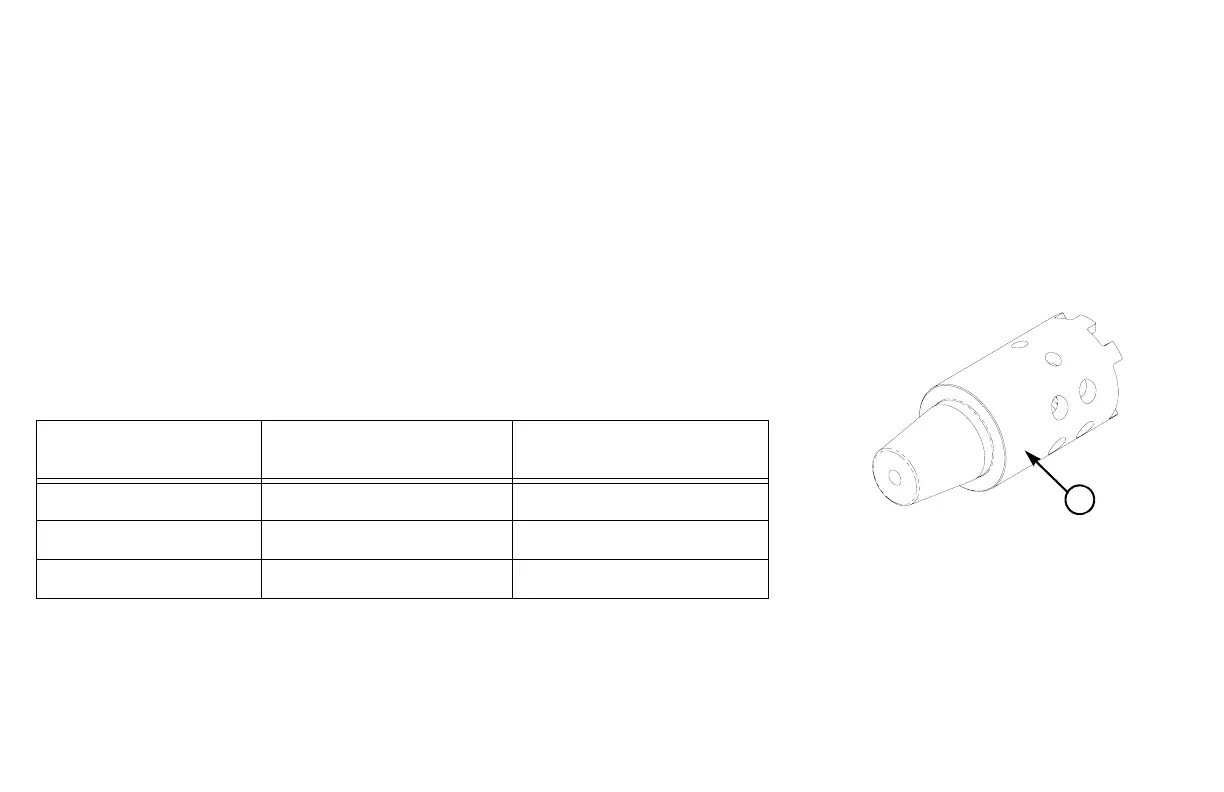

IMPORTANT: If using an API crossover connector (1), it is important to be aware that proper

makeup torque of the crossover sub to the reamer is crucial. Failure to torque API joints to the

following minimum specifications can result in joint separation or other failures of tooling. In

some cases, properly torquing the joints will require the use of a Portable Breakout system.

API Connection Size Minimum Makeup Torque

Suggested Maximum

Operating Torque

2-3/8″ API Regular 1,560 ft-lb (2115 Nm) 2,600 ft-lb (3526 Nm)

2-7/8″ API Regular 3,000 ft-lb (4068 Nm) 5,000 ft-lb (6780 Nm)

3-1/2″ API Regular 7,200 ft-lb (9763 Nm) 12,000 ft-lb (16272 Nm)

1

Loading...

Loading...