D7x11 Series II Navigator Directional Drill Overview 30-29

Drill Rods - Add to Drill String

NOTE: The floating drive head will move forward as rods thread.

Step 1: Drive drill rod into the ground. Stop rotation and shut off fluid.

Step 2: Engage front vise.

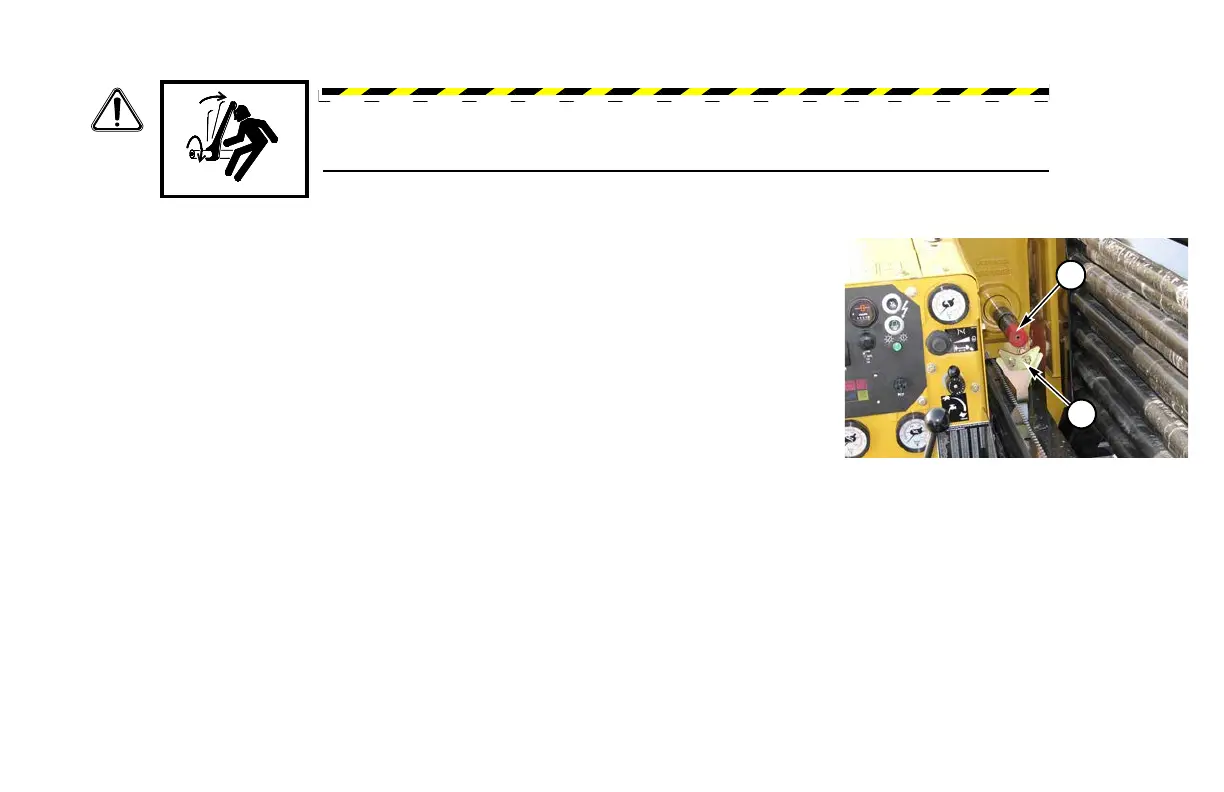

Step 3: Use Thrust Lever to move carriage (1) backward to allow drive head to float

back as the rod unthreads.

Step 4: Rotate drive chuck in reverse to unthread drill rod.

Step 5: Move drive head back to align threads with auto greaser nozzle or back

within reach for hand greasing. Grease the drive chuck threads.

Step 6: Move drive head fully back.

Step 7: Retrieve a drill rod from the rod box and bring into drilling position. Place

front in vise and rear in cradle (2).

NOTE: If rust or debris could be inside the rod, flush drill rod with drilling fluid before connecting lower joint.

Slowly rotate rod while pumping fluid through it. Shut off fluid before connecting to the drill string.

NOTE: The drill rod joints can be cleaned with a spray wand.

Step 8: Lubricate threads of drill rod pin to be added. Refer to Lubricants section in the Maintenance Manual.

IMPORTANT: Keep electrically insulated gloves from touching thread lube. Petroleum-based products will

chemically damage the rubber insulating gloves.

DANGER: Wrench on rotating drill string can strike you. Death or serious injury will

result. Always use the power vise to make or break joints at the machine.

1

2

4_00

Loading...

Loading...