50-36 Operation D7x11 Series II Navigator Directional Drill

FLUSHING BENTONITE/POLYMERS FROM DRILLING FLUID SYSTEM

If bentonite or polymers were added to drilling fluid, flush system with fresh water before stowing equipment.

Step 1: Turn water system on and flush water through machine hoses and drive plate. Shut off water system.

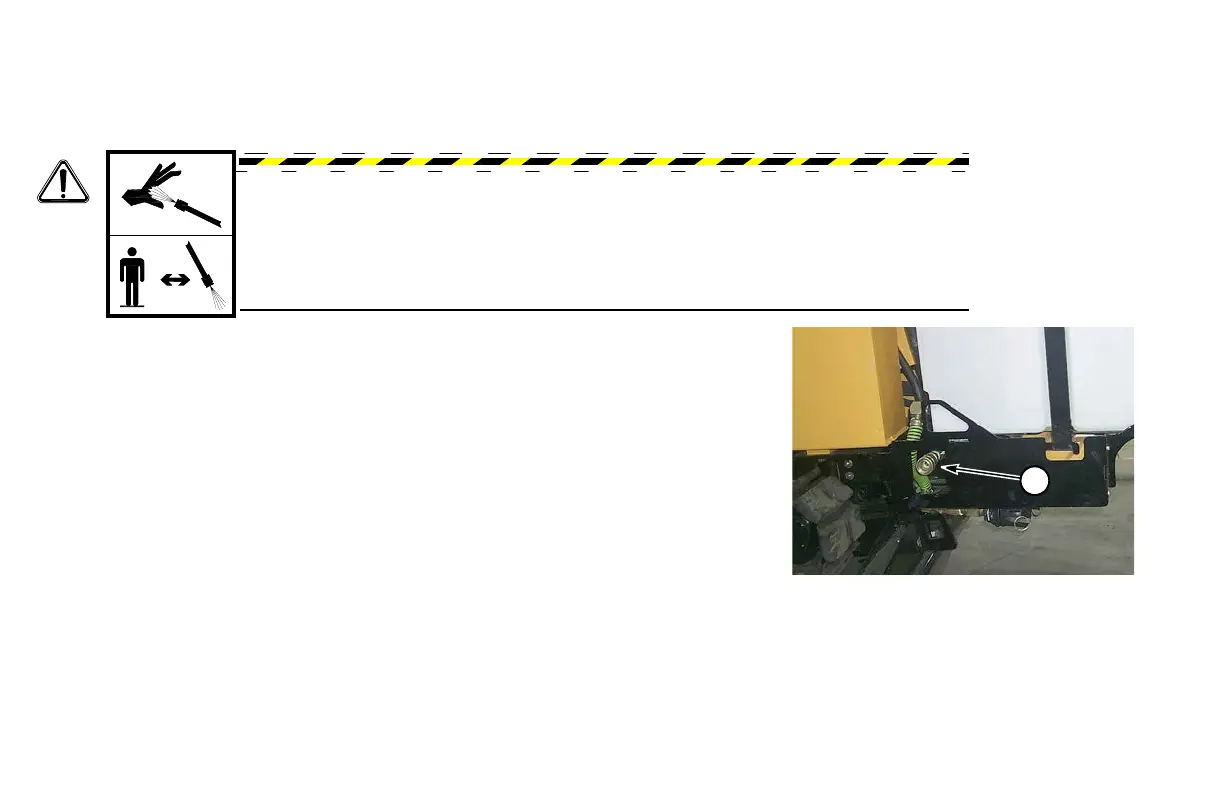

Step 2: Connect wash wand to drilling fluid pump quick coupler (1).

Step 3: Turn water system on and flush water through wash wand until water is

clean and clear.

Step 4: Shut off water system.

Step 5: Point wash wand away from people and squeeze handle to release water

pressure remaining in wand.

Step 6: Remove wash wand from drilling fluid pump quick coupler and store on

transport vehicle.

NOTE: If freezing weather is expected, remove all water from drill unit or add RV-

type antifreeze. Refer to the Overview section, “Adding Antifreeze to Drilling Fluid

System,” page 30-34.

Machine - Wash

Before loading onto transport vehicle, use procedure on previous page to wash drill unit with clean water to

remove accumulated polymers and dirt.

WARNING: High pressure water can penetrate skin. Serious injury possible. Fluid

injected under the skin must be removed immediately by a surgeon familiar with this

type of injury.

Keep nozzles away from body.

1

4_00

Loading...

Loading...