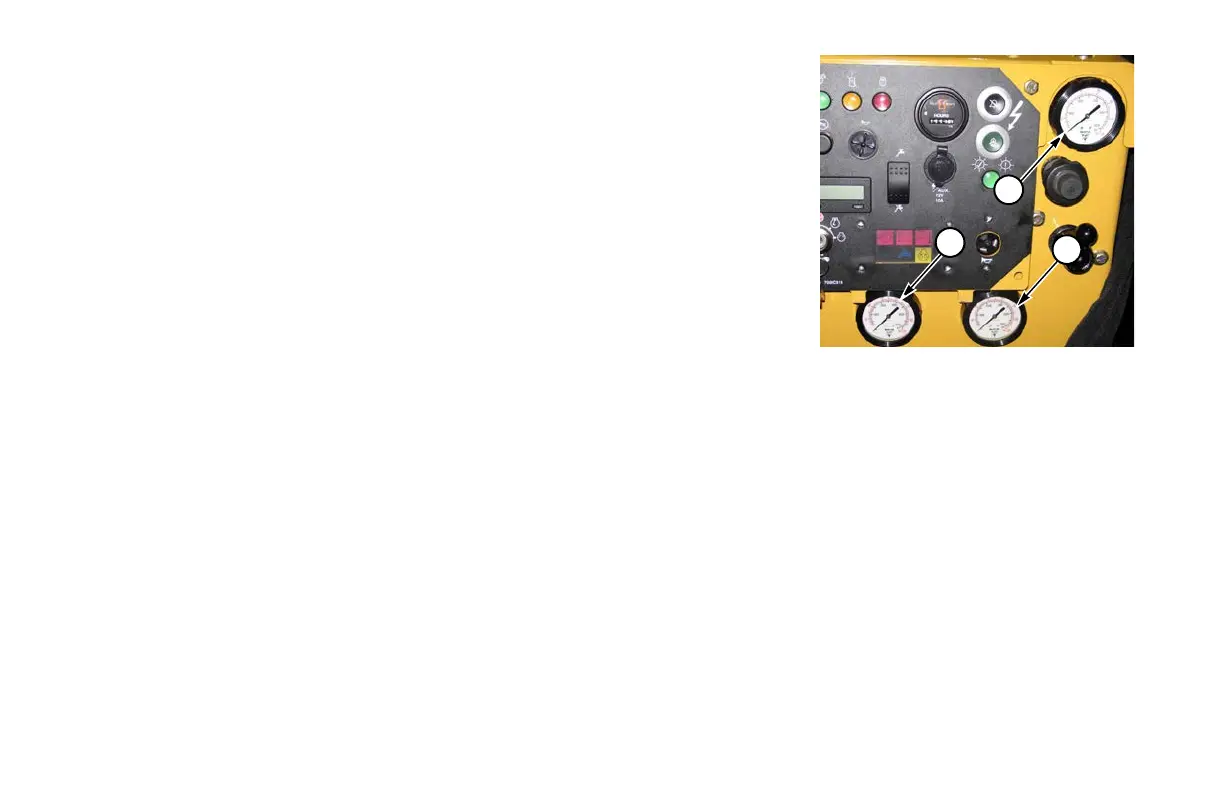

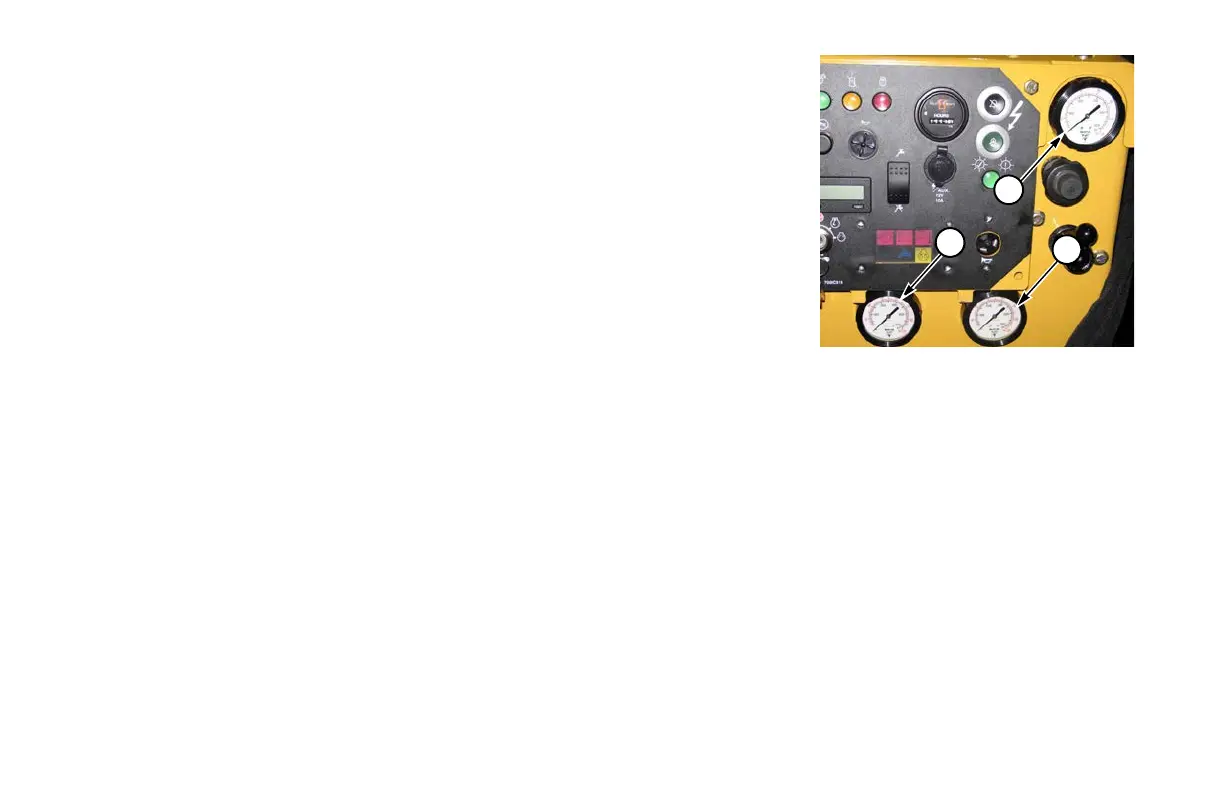

50-34 Operation D7x11 Series II Navigator Directional Drill

GAUGES - MONITOR DURING PULLBACK

Monitor gauges during drilling operation to ensure a good pilot bore. Watching the gauges

will help establish a baseline for rotation and thrust/pullback pressures. Ideally, the

pullback pressure will remain low while the reamer mixes drilling fluid with the soil to

form a good slurry flow through the annular space.

Rotation Pressure (1)–If rotation pressure is spiking, you may be pulling back too fast

for the ground conditions. A rise in rotation pressure can also mean that the reamer has

encountered harder ground.

Thrust/Pullback Pressure (2)–A steady rise in pullback pressure could indicate a loss

of fluid flow through the annular space, causing the product to become stuck or a frac-out

to occur.

Drilling Fluid Pressure (3)–The drilling fluid pressure gauge is best used as an

indicator that flow is occurring. Pressure can vary based on flow rates and nozzle sizes used in the tooling. A

maximum indication on the drilling fluid pressure gauge could be an indicator that flow has become restricted.

DRILL ROD - REMOVE

Refer to the Overview section, “Drill Rods - Remove from Drill String,” page 30-31, for procedures.

1

2

3

Loading...

Loading...