Engin eering

T2-28

© WMF800 / 900 / 1000S / 1000proS Edition 07/2014 - KMT

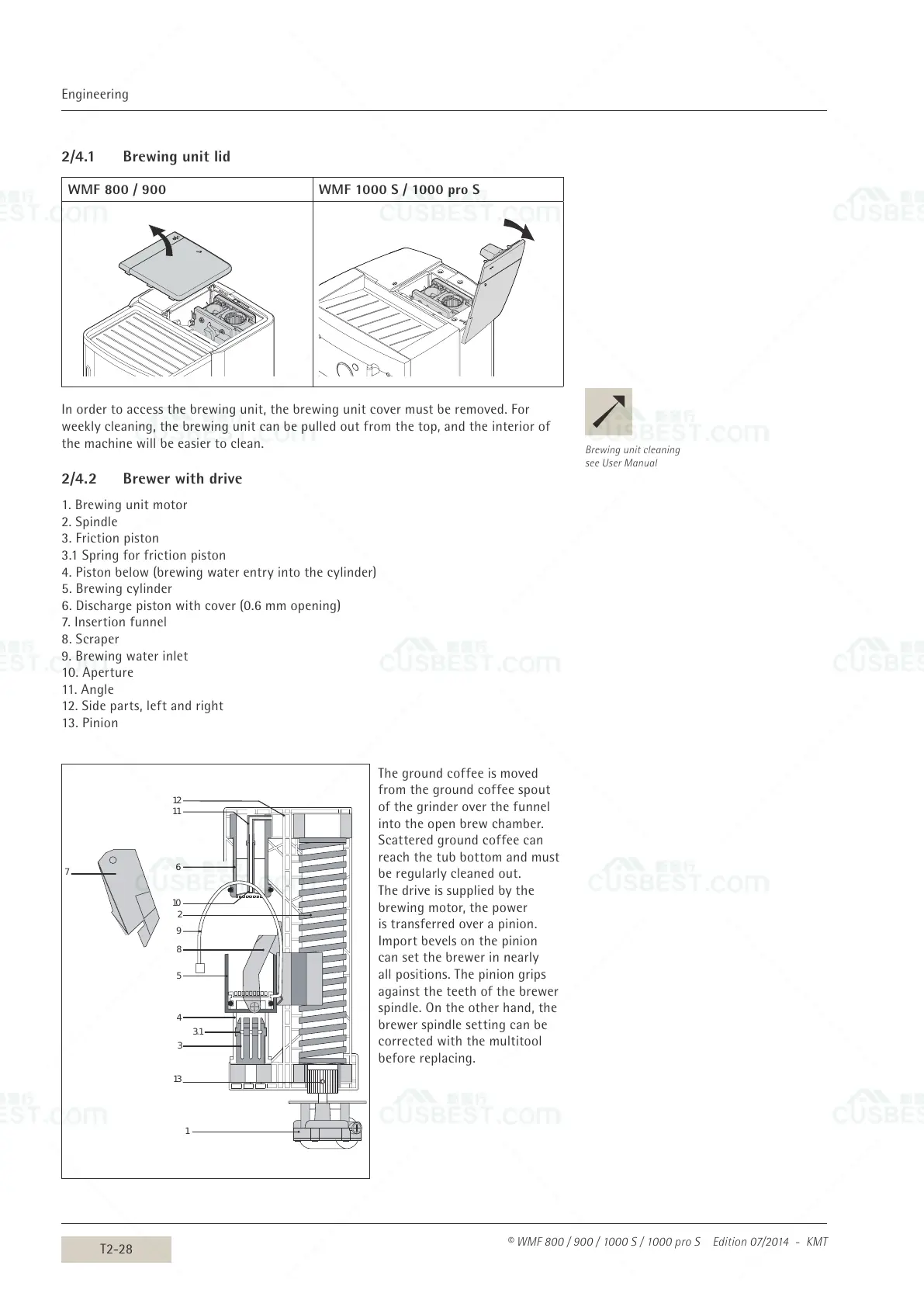

2/4.1 Brewing unit lid

WMF800 / 900 WMF1000S / 1000proS

In order to access the brewing unit, the brewing unit cover must be removed. For

weekly cleaning, the brewing unit can be pulled out from the top, and the interior of

the machine will be easier to clean.

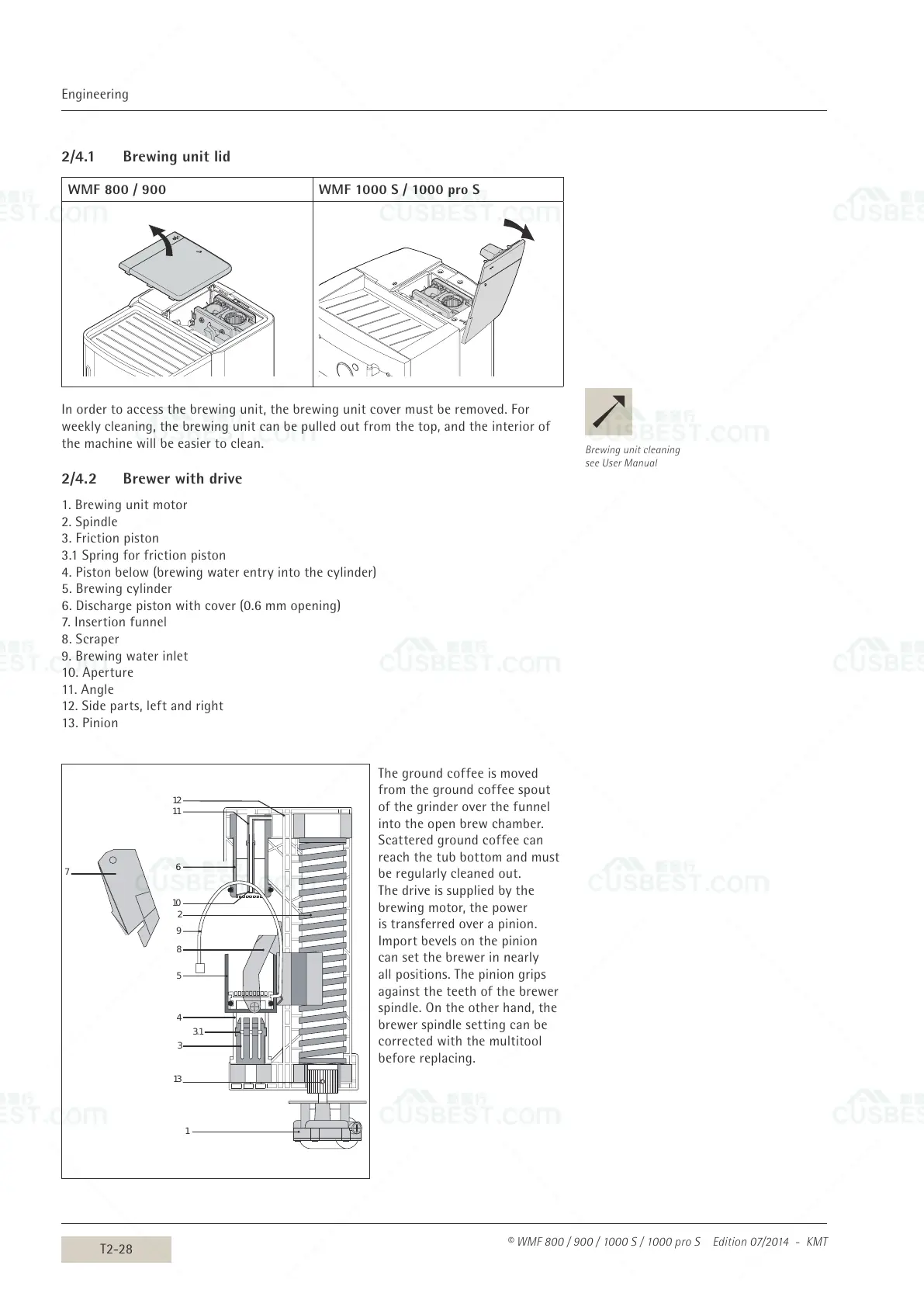

2/4.2 Brewer with drive

1. Brewing unit motor

2. Spindle

3. Friction piston

3.1Spring for friction piston

4. Piston below (brewing water entry into the cylinder)

5. Brewing cylinder

6. Discharge piston with cover (0.6mm opening)

7. Insertion funnel

8. Scraper

9. Brewing water inlet

10. Aperture

11. Angle

12. Side parts, left and right

13. Pinion

The ground coffee is moved

from the ground coffee spout

of the grinder over the funnel

into the open brew chamber.

Scattered ground coffee can

reach the tub bottom and must

be regularly cleaned out.

The drive is supplied by the

brewing motor, the power

is transferred over apinion.

Import bevels on the pinion

can set the brewer in nearly

all positions. The pinion grips

against the teeth of the brewer

spindle. On the other hand, the

brewer spindle setting can be

corrected with the multitool

before replacing.

Brewing unit cleaning

see User Manual

12

11

6

10

2

9

8

5

4

3

1

7

13

3.1

Loading...

Loading...