Engin eering

T2-30

© WMF800 / 900 / 1000S / 1000proS Edition 07/2014 - KMT

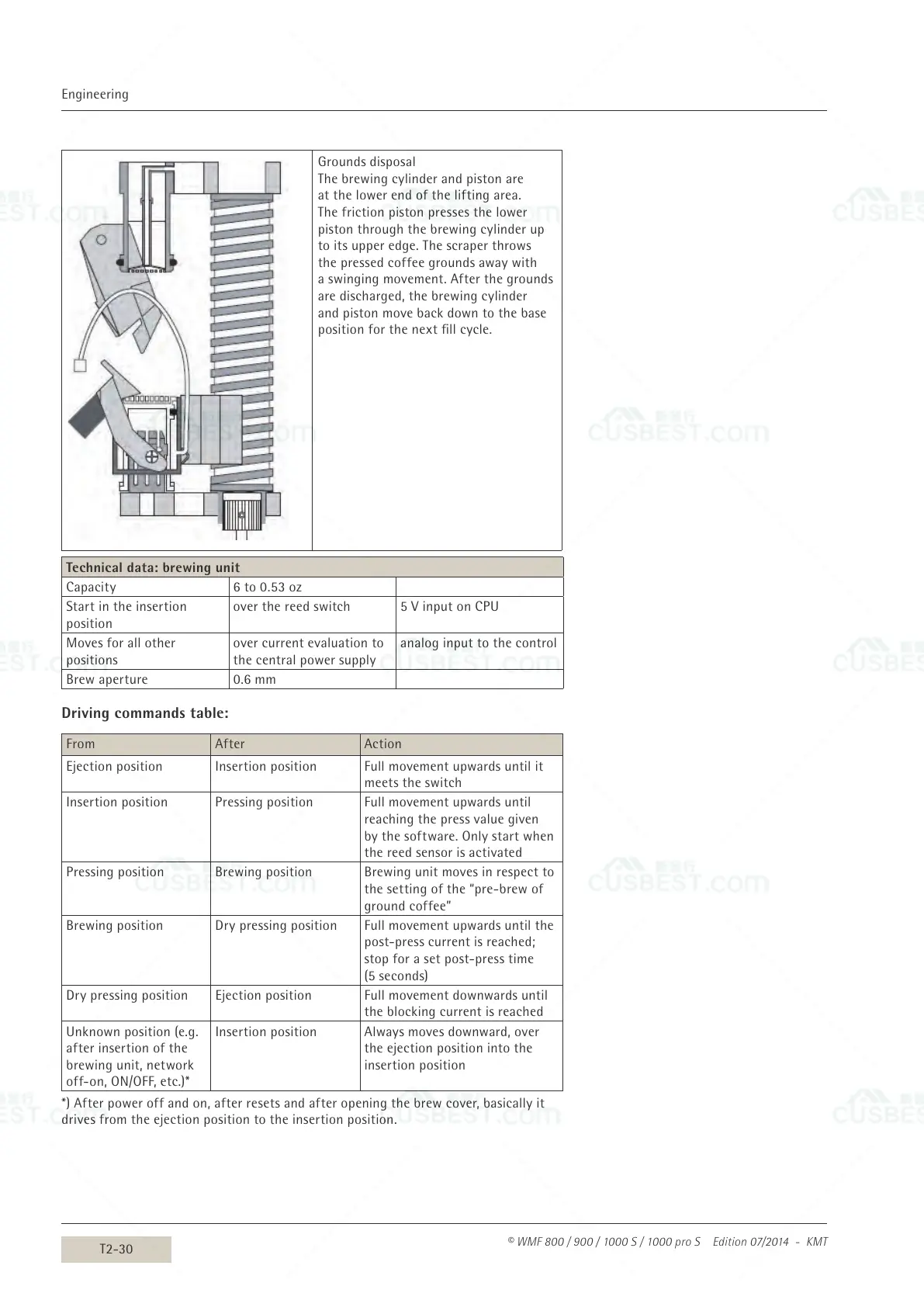

Grounds disposal

The brewing cylinder and piston are

at the lower end of the lifting area.

The friction piston presses the lower

piston through the brewing cylinder up

to its upper edge. The scraper throws

the pressed coffee grounds away with

aswinging movement. After the grounds

are discharged, the brewing cylinder

and piston move back down to the base

position for the next fill cycle.

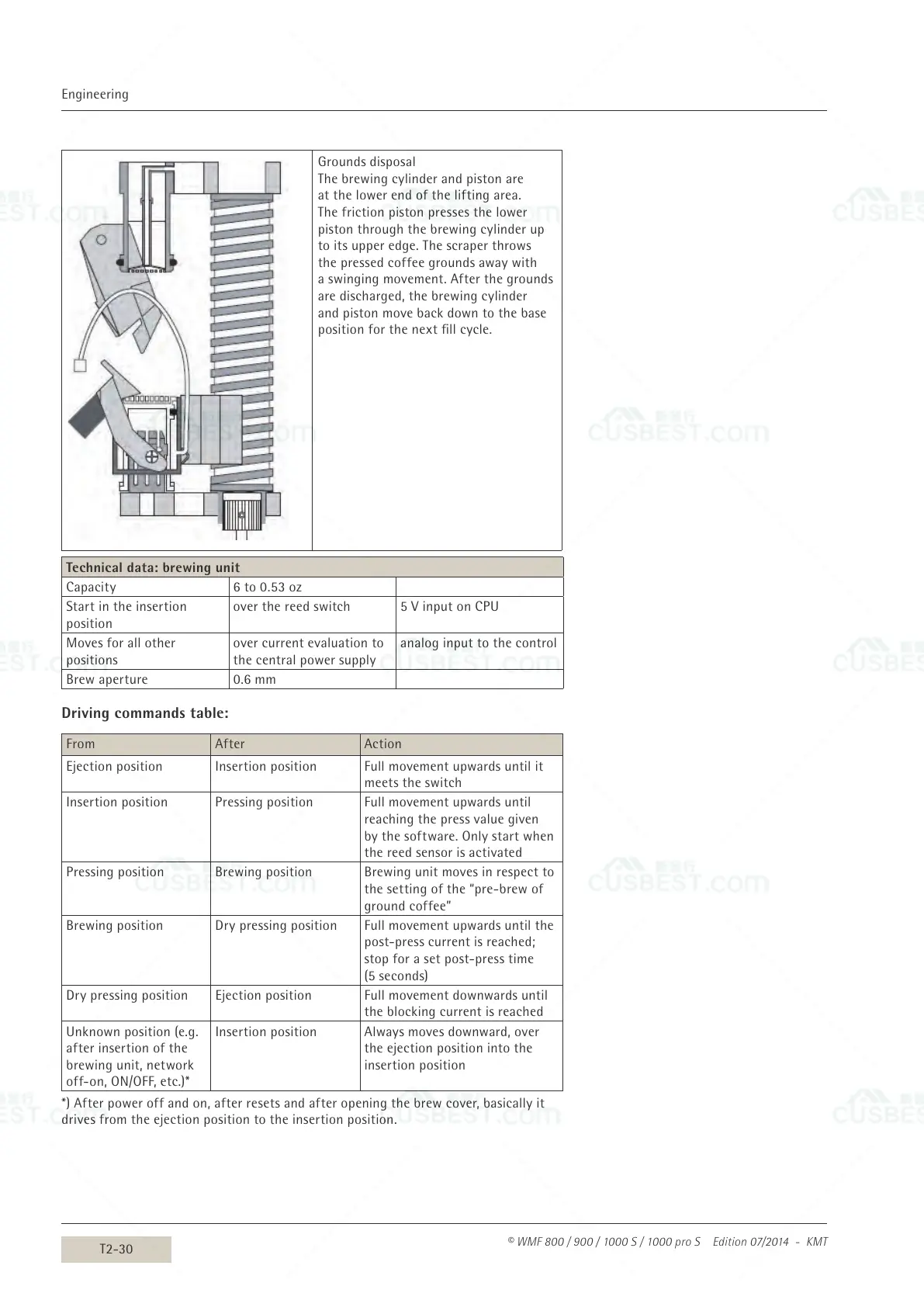

Technical data: brewing unit

Capacity 6to 0.53oz

Start in the insertion

position

over the reed switch 5V input on CPU

Moves for all other

positions

over current evaluation to

the central power supply

analog input to the control

Brew aperture 0.6mm

Driving commands table:

From After Action

Ejection position Insertion position Full movement upwards until it

meets the switch

Insertion position Pressing position Full movement upwards until

reaching the press value given

by the software. Only start when

the reed sensor is activated

Pressing position Brewing position Brewing unit moves in respect to

the setting of the “pre-brew of

ground coffee”

Brewing position Dry pressing position Full movement upwards until the

post-press current is reached;

stop for aset post-press time

(5seconds)

Dry pressing position Ejection position Full movement downwards until

the blocking current is reached

Unknown position (e.g.

after insertion of the

brewing unit, network

off-on, ON/OFF, etc.)*

Insertion position Always moves downward, over

the ejection position into the

insertion position

*) After power off and on, after resets and after opening the brew cover, basically it

drives from the ejection position to the insertion position.

Loading...

Loading...