5-67

CRANKCASE

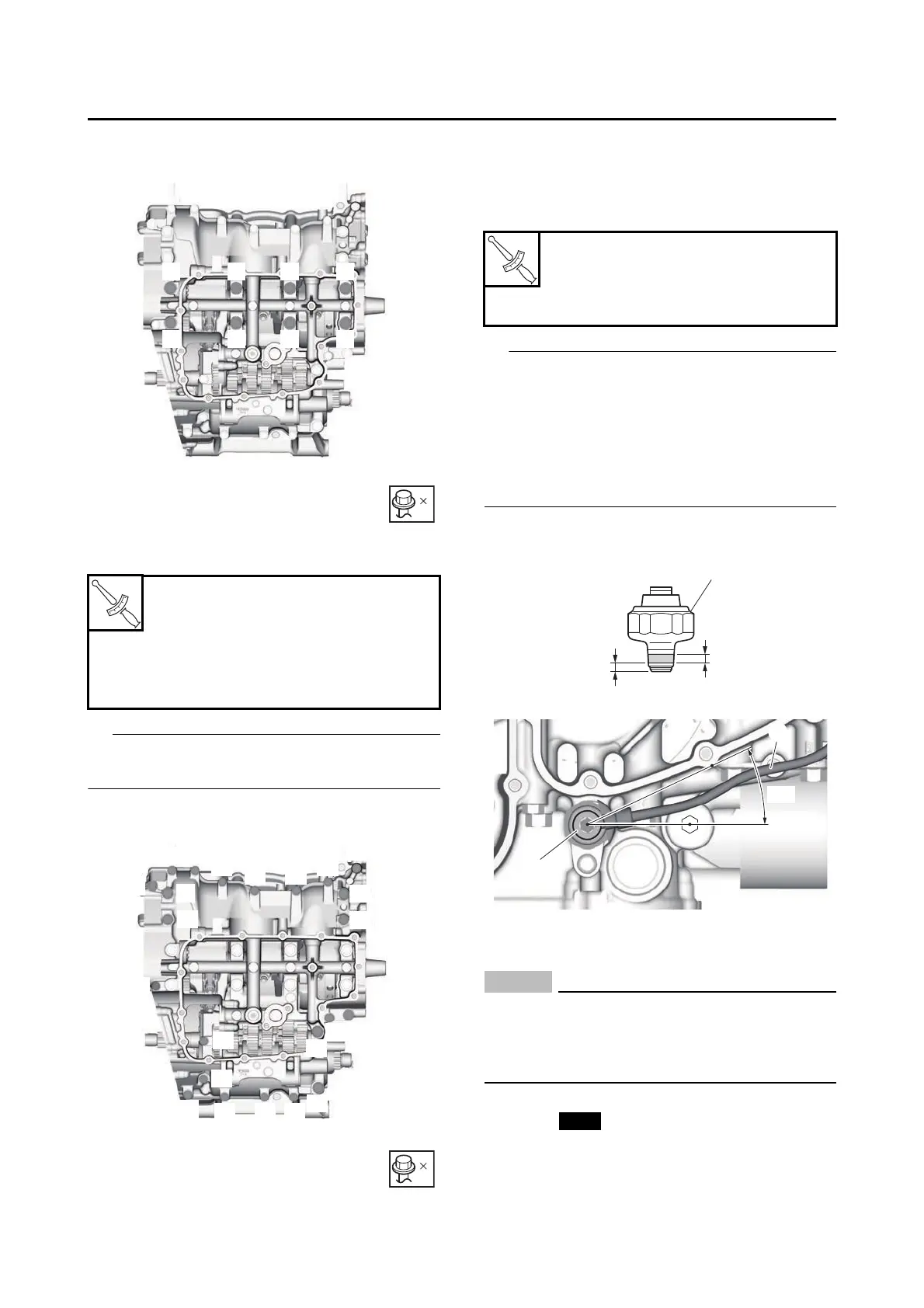

8. Tighten:

• Crankcase bolt “9”–“31”

Tighten the bolts in the tightening sequence cast

on the crankcase.

EAS31071

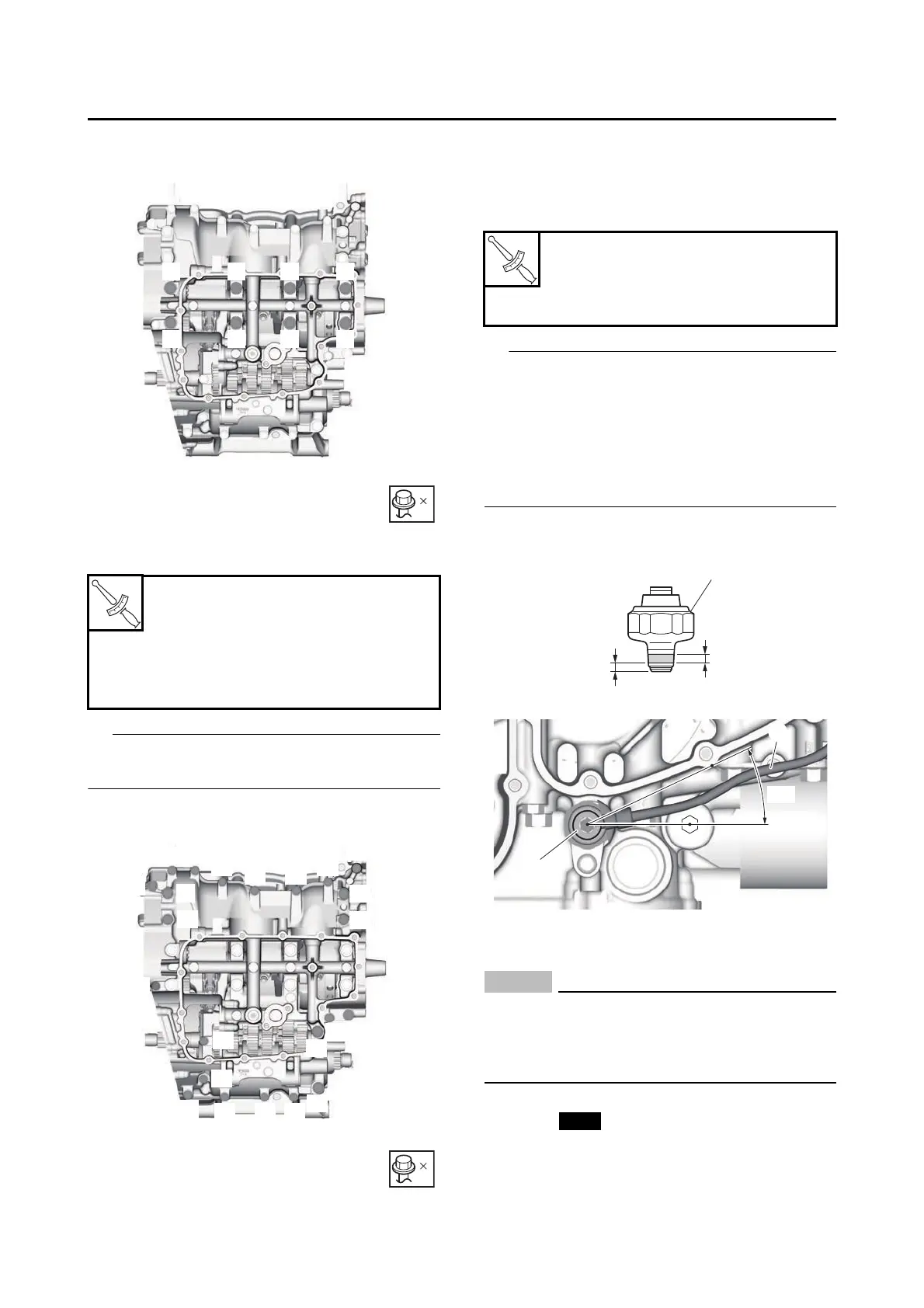

INSTALLING THE OIL PRESSURE SWITCH

1. Install:

• Oil pressure switch “1”

• Oil pressure switch lead “2”

• Apply Three Bond No. 1215B® to the threads

“a” of the oil pressure switch. However, do not

apply Three Bond No. 1215B® to the portion

“b” of the oil pressure switch.

• Install the oil pressure switch lead so that it is

routed within the range shown in the illustra-

tion.

EAS31658

INSTALLING THE GEAR POSITION SENSOR

NOTICE

ECA22630

To prevent damage to the gear position sen-

sor, keep magnets (including any pickup tool

with a magnet, magnetized screwdrivers,

etc.) away from the gear position sensor.

1. Install:

• O-ring

• Gear position sensor “1”

Crankcase bolts “9”–“12”

22 N·m (2.2 kgf·m, 16 lb·ft)

Crankcase bolts “13”–“14”

24 N·m (2.4 kgf·m, 18 lb·ft)

Crankcase bolts “15”–“31”

10 N·m (1.0 kgf·m, 7.4 lb·ft)

23

9

10

12

11

13

14

15

16

17

18

19

20

21

22

23

24

25

26

272829

30

31

Oil pressure switch

13 N·m (1.3 kgf·m, 9.6 lb·ft)

Oil pressure switch lead bolt

1.8 N·m (0.18 kgf·m, 1.3 lb·ft)

Loading...

Loading...