6.6 Position Control

6-29

6.6

Position Control

Position control is used to input a pulse train reference from the host controller to the SERVO-

PACK to move to a target position. The position is controlled with the number of input pulses,

and the speed is controlled with the input pulse frequency. Use position control when position-

ing is required.

You set the control method to position control in Pn000 = n.X (Control Method Selection).

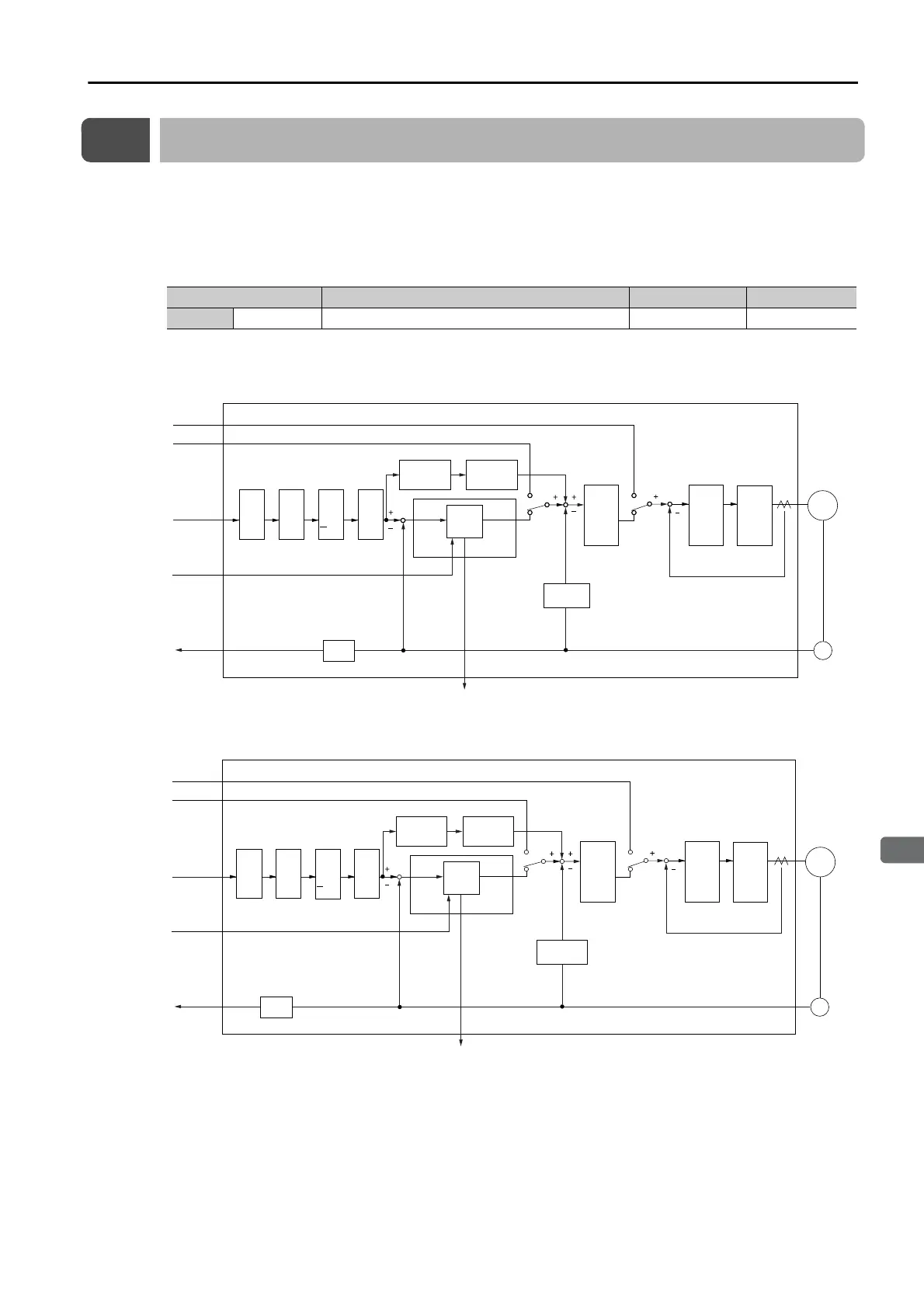

The control block diagrams for position control are provided below.

• Rotary Servomotors

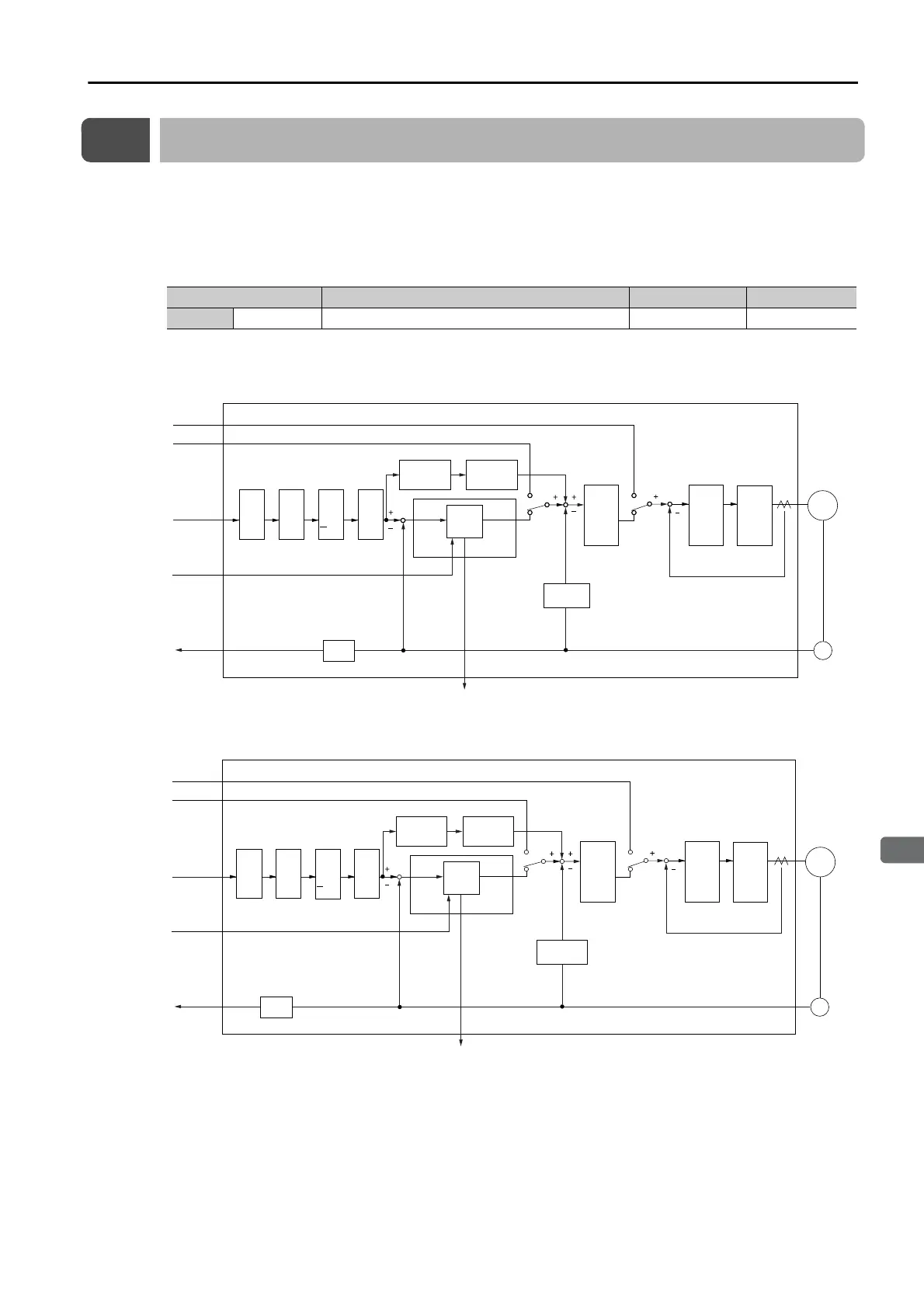

• Linear Servomotors

Parameter Meaning When Enabled Classification

Pn000 n.1 Position Control After restart Setup

Pn10A

ENC

M

Pn000

= n.

X

Pn000

= n.

X

Pn200

= n.

X

Pn218

Pn109

Pn20E

Pn210

COIN

Pn212

Pn216

Pn217

SERVOPACK

Torque

reference

Speed

reference

Position

reference

Refer-

ence

pulse

form

Refer-

ence

pulse

input

n

Elec-

tronic

gear

B

A

Smo-

othing

Deviation

counter

Speed

control

section

Current

control

section

Power

amplier

Servomotor

Current feedback

Feedforward

Feedforward

lter time

constant

Clear

signal input

Encoder

divided pulse

output

Divider

Speed

conversion

Position

feedback

Pn522 (Positioning

Completed Width)

Speed feedback

Position

control section

Pn10A

ENC

M

Pn000

= n.

X

Pn000

= n.

X

Pn109

COIN

Pn281

Pn216

Pn217

Pn200

= n.

X

Pn218 Pn20E

Pn210

SERVOPACK

Feedforward

Feedforward

lter time

constant

Deviation

counter

Position

control section

Position

feedback

Pn522 (Positioning

Completed Width)

Speed feedback

Speed

control

section

Current

control

section

Power

amplier

Servomotor

Linear

encoder

Current feedback

Force

reference

Speed

reference

Position

reference

Clear signal

input

Encoder

divided pulse

output

Divider

Refer-

ence

pulse

form

Refer-

ence

pulse

input

n

Speed

conversion

Elec-

tronic

gear

B

A

Smo-

othing

Loading...

Loading...