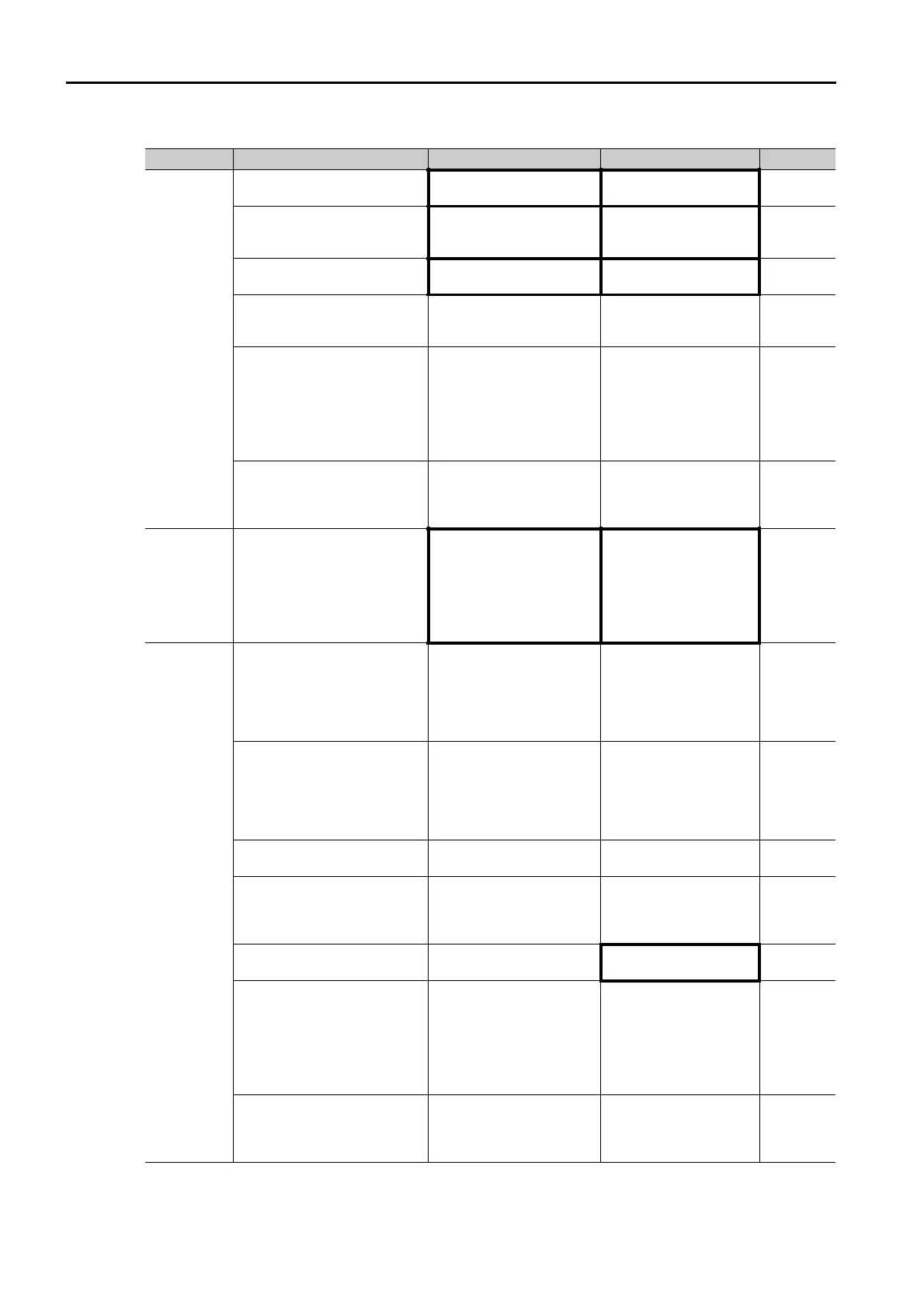

12.4 Troubleshooting Based on the Operation and Conditions of the Servomotor

12-54

Servomotor

Moves

Instanta-

neously,

and Then

Stops

There is a mistake in the Ser-

vomotor wiring.

Check the wiring.

Wire the Servomotor

correctly.

–

There is a mistake in the wir-

ing of the encoder or Serial

Converter Unit.

Check the wiring.

Wire the Serial Con-

verter Unit correctly.

–

There is a mistake in the lin-

ear encoder wiring.

Check the wiring.

Wire the cable cor-

rectly.

–

The setting of Pn282 (Linear

Encoder Scale Pitch) is not

correct.

Check the setting of

Pn282.

Correct the setting of

Pn282.

page 5-19

The count-up direction of the

linear encoder does not

match the forward direction

of the Moving Coil in the

motor.

Check the directions.

Change the setting of

Pn080 = n.X

(Motor Phase

Sequence Selection).

Place the linear

encoder and motor in

the same direction.

page 5-25

Polarity detection was not

performed correctly.

Check to see if electrical

angle 2 (electrical angle

from polarity origin) at any

position is between ±10°.

Correct the settings for

the polarity detection-

related parameters.

–

Servomotor

Speed Is

Unstable

There is a faulty connection

in the Servomotor wiring.

The connector connec-

tions for the power line

(U, V, and W phases) and

the encoder or Serial

Converter Unit may be

unstable. Check the wir-

ing.

Tighten any loose ter-

minals or connectors

and correct the wiring.

–

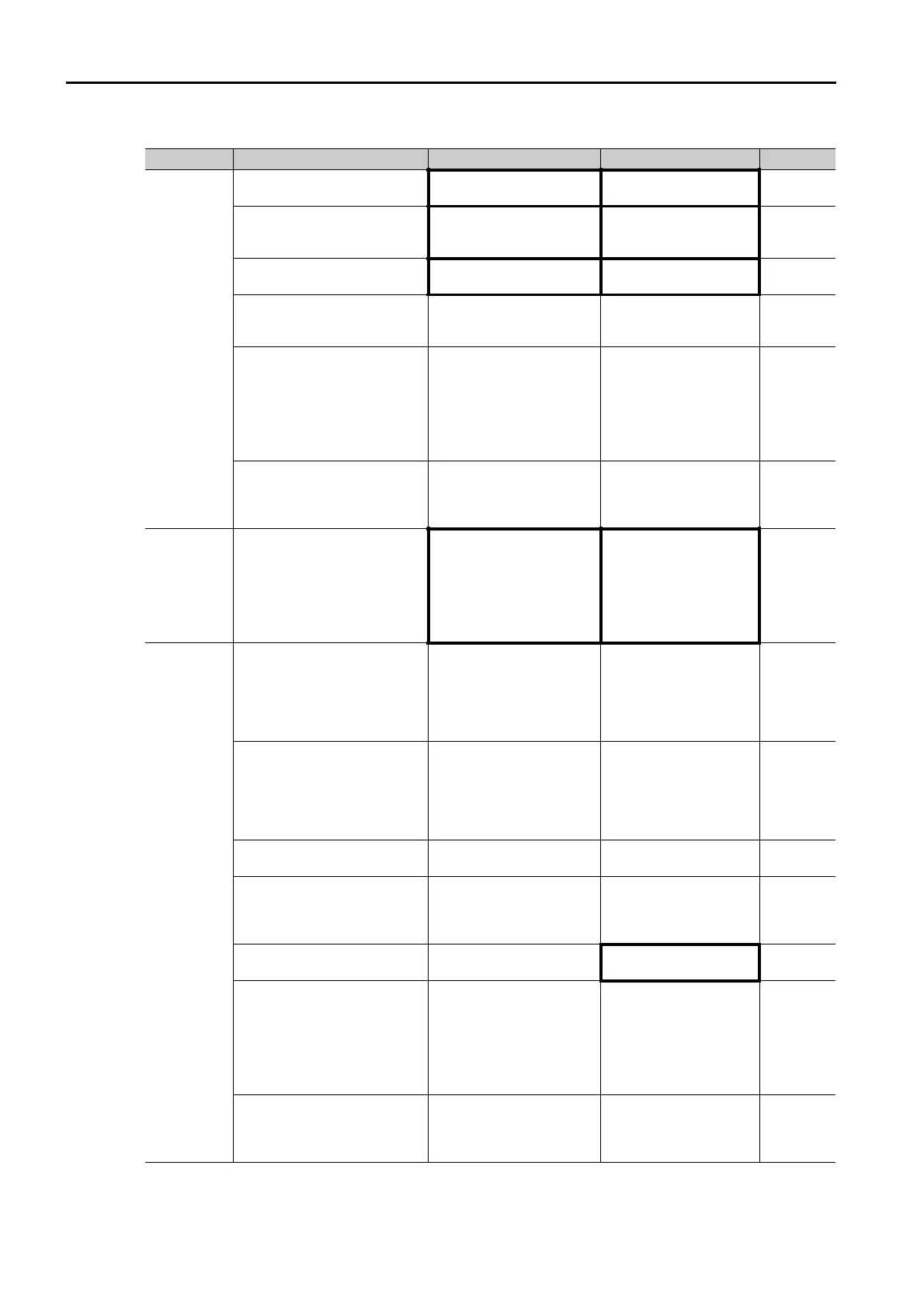

Servomotor

Moves with-

out a Refer-

ence Input

Speed control: The speed

reference input is not appro-

priate.

Check between the

speed reference input (V-

REF) and signal ground

(SG) to see if the control

method and the input

agree.

Correctly set the con-

trol method and input

method.

page 9-7

Torque control: The torque

reference input is not appro-

priate.

Check between the

torque reference input (T-

REF) and signal ground

(SG) to see if the control

method and the input

agree.

Correctly set the con-

trol method and input

method.

page 9-7

The speed reference offset is

not correct.

The SERVOPACK offset

is adjusted incorrectly.

Adjust the SERVO-

PACK offset.

page 6-18

Position control: The refer-

ence pulse input is not

appropriate.

Check the setting of

Pn200 =n.X (Refer-

ence Pulse Form) and the

sign and pulse signals.

Correctly set the con-

trol method and input

method.

–

A failure occurred in the

SERVOPACK.

–

Replace the SERVO-

PACK.

–

The count-up direction of the

linear encoder does not

match the forward direction

of the Moving Coil in the

motor.

Check the directions.

Change the setting of

Pn080 = n.X

(Motor Phase

Sequence Selection).

Match the linear

encoder direction and

Servomotor direction.

page 5-25

Polarity detection was not

performed correctly.

Check to see if electrical

angle 2 (electrical angle

from polarity origin) at any

position is between ±10°.

Correct the settings for

the polarity detection-

related parameters.

–

Continued on next page.

Continued from previous page.

Problem Possible Cause Confirmation Correction Reference

Loading...

Loading...