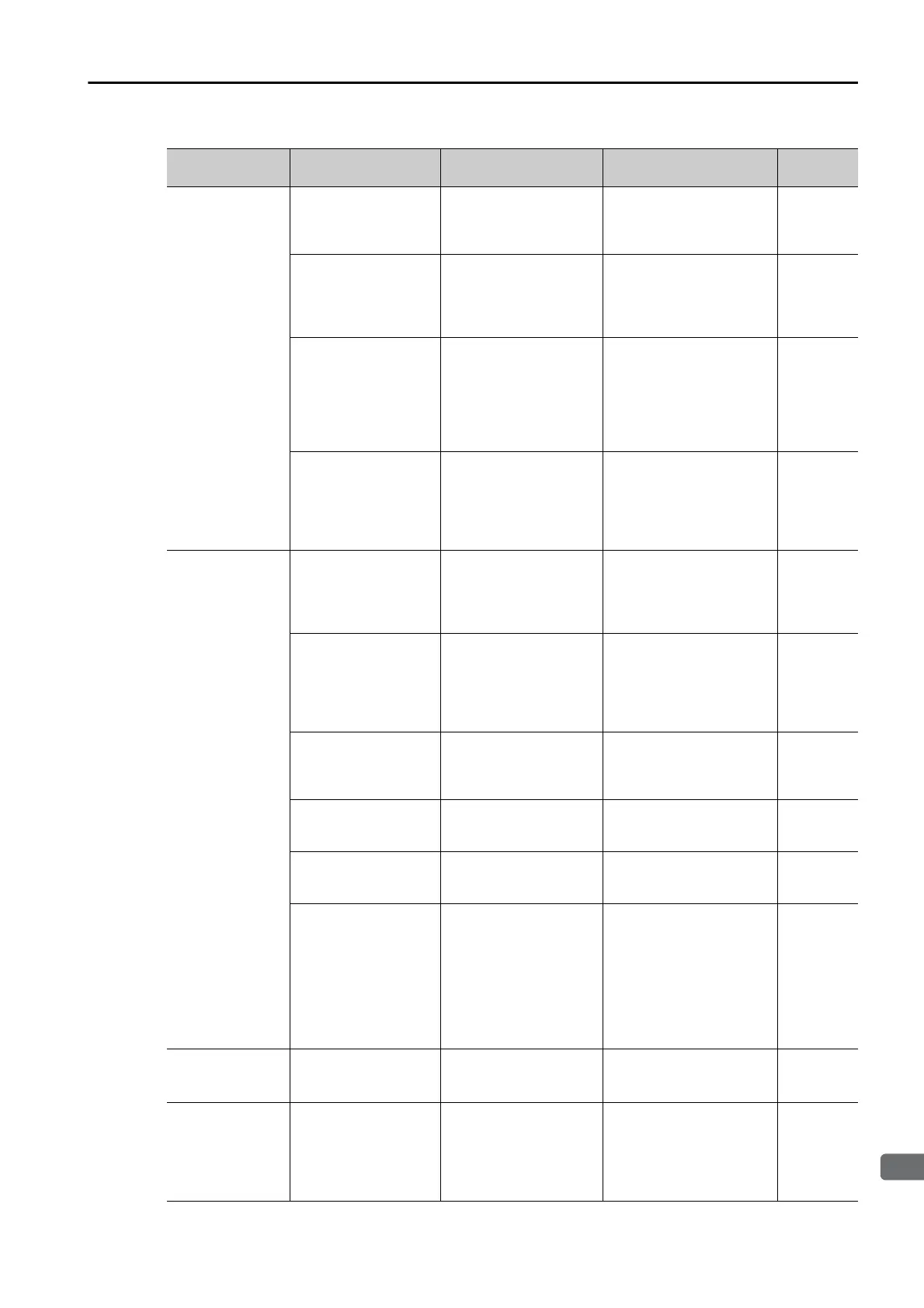

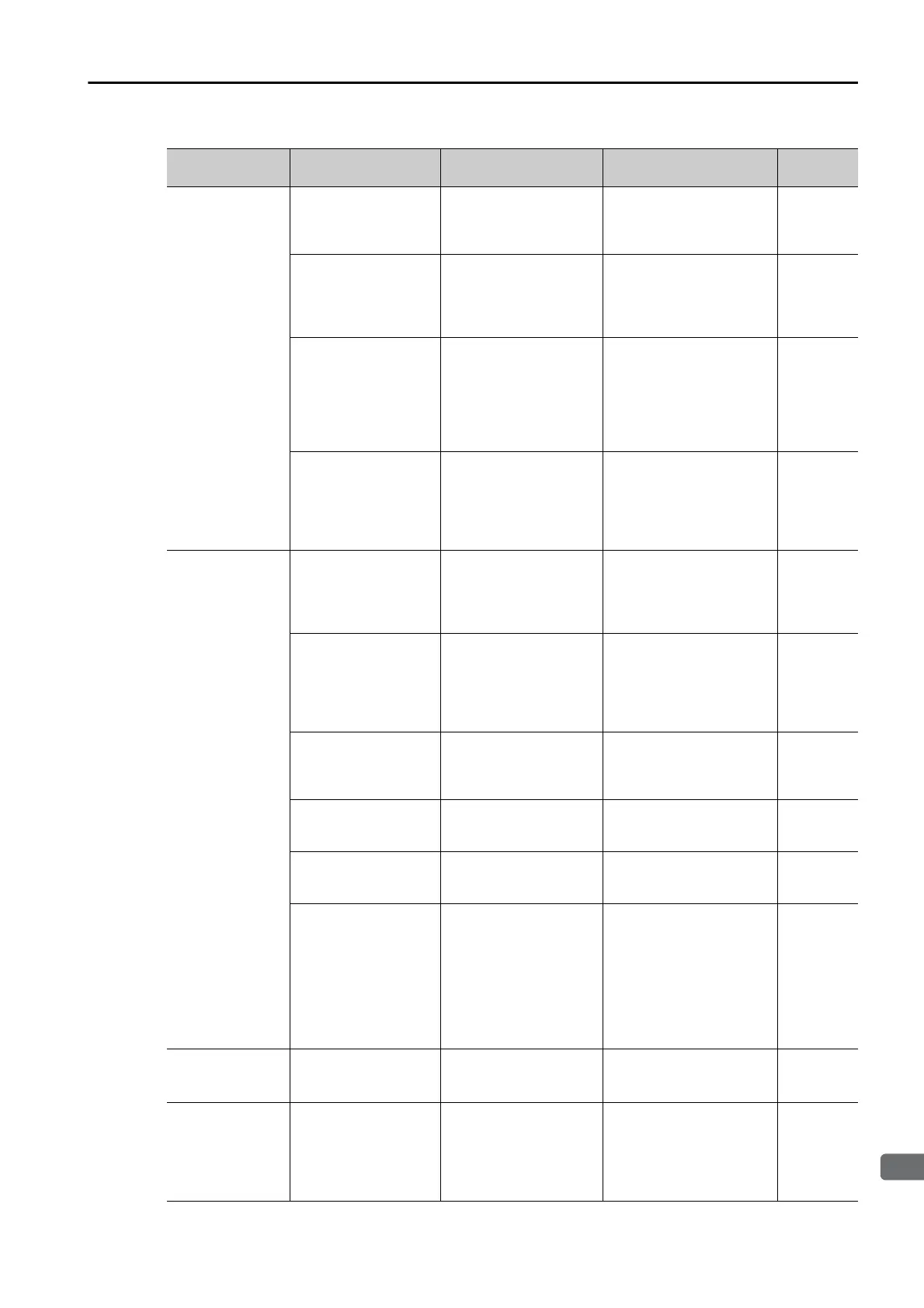

6.1 Alarm Displays

6.1.2 Troubleshooting Alarms

6-21

A.861:

Motor Over-

heated

The surrounding tem-

perature around the

Servomotor is too

high.

Measure the surround-

ing temperature around

the Servomotor.

Reduce the surrounding

air temperature of the

Servomotor to 40°C or

less.

–

The motor load is

greater than the rated

load.

Check the load with the

accumulated load ratio

on the Motion Monitor

Tab Page on the Sig-

maWin+.

Operate the Servo Drive

so that the motor load

remains within the speci-

fied range.

*1

A failure occurred in

the Serial Converter

Unit.

–

Turn the power supply to

the SERVOPACK OFF and

ON again. If the alarm still

occurs, the Serial Con-

verter Unit may be faulty.

Replace the Serial Con-

verter Unit.

–

A failure occurred in

the SERVOPACK.

–

Turn the power supply to

the SERVOPACK OFF and

ON again. If the alarm still

occurs, the SERVOPACK

may be faulty. Replace the

SERVOPACK.

–

A.862:

Overheat Alarm

The surrounding tem-

perature is too high.

Check the surrounding

temperature using a

thermometer.

Lower the surrounding

temperature by improving

the installation conditions

of the Linear Servomotor

or the machine.

–

The overheat protec-

tion input signal line is

disconnected or

short-circuited.

Check the input voltage

with the overheat pro-

tection input information

on the Motion Monitor

Tab Page on the Sig-

maWin+.

Repair the line for the

overheat protection input

signal.

–

An overload alarm

was reset by turning

OFF the power sup-

ply too many times.

Check the alarm display

to see if there is an

overload alarm.

Change the method for

resetting the alarm.

–

Operation was per-

formed under an

excessive load.

Use the accumulated

load ratio to check the

load during operation.

Reconsider the load and

operating conditions.

–

A failure occurred in

the SERVOPACK.

–

The SERVOPACK may be

faulty. Replace the

SERVOPACK.

–

The temperature

detection circuit in the

Linear Servomotor is

faulty or the sensor

attached to the

machine is faulty.

–

The temperature detec-

tion circuit in the Linear

Servomotor may be faulty

or the sensor attached to

the machine may be

faulty. Replace the Linear

Servomotor or repair the

sensor attached to the

machine.

–

A.890:

Encoder Scale

Error

A failure occurred in

the linear encoder.

–

The linear encoder may

be faulty. Replace the lin-

ear encoder.

–

A.891:

Encoder Module

Error

A failure occurred in

the linear encoder.

–

Turn the power supply to

the SERVOPACK OFF and

ON again. If the alarm still

occurs, the linear encoder

may be faulty. Replace the

linear encoder.

–

Continued on next page.

Continued from previous page.

Alarm Number:

Alarm Name

Possible Cause Confirmation Correction Reference

Loading...

Loading...