6.1 Alarm Displays

6.1.2 Troubleshooting Alarms

6-33

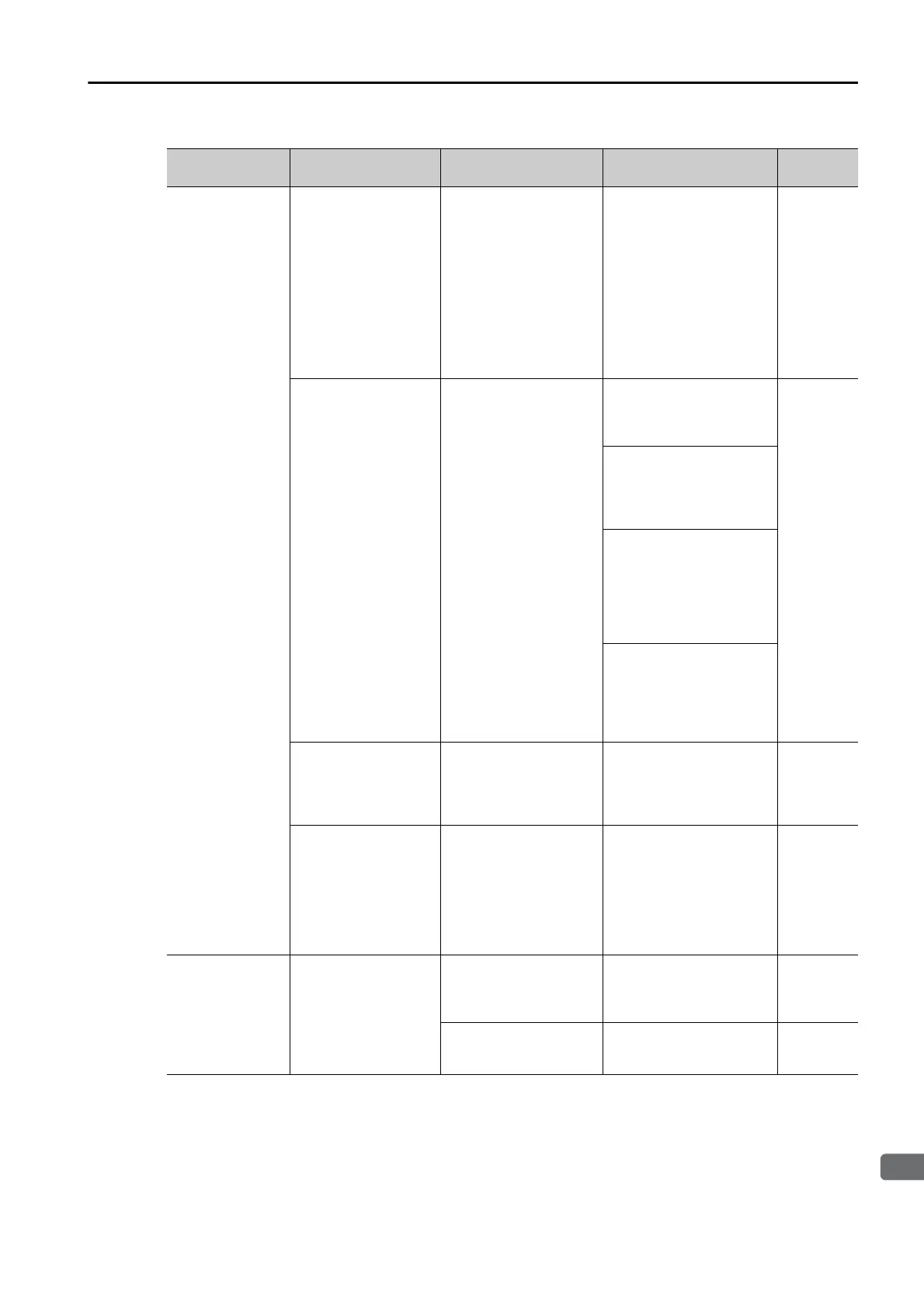

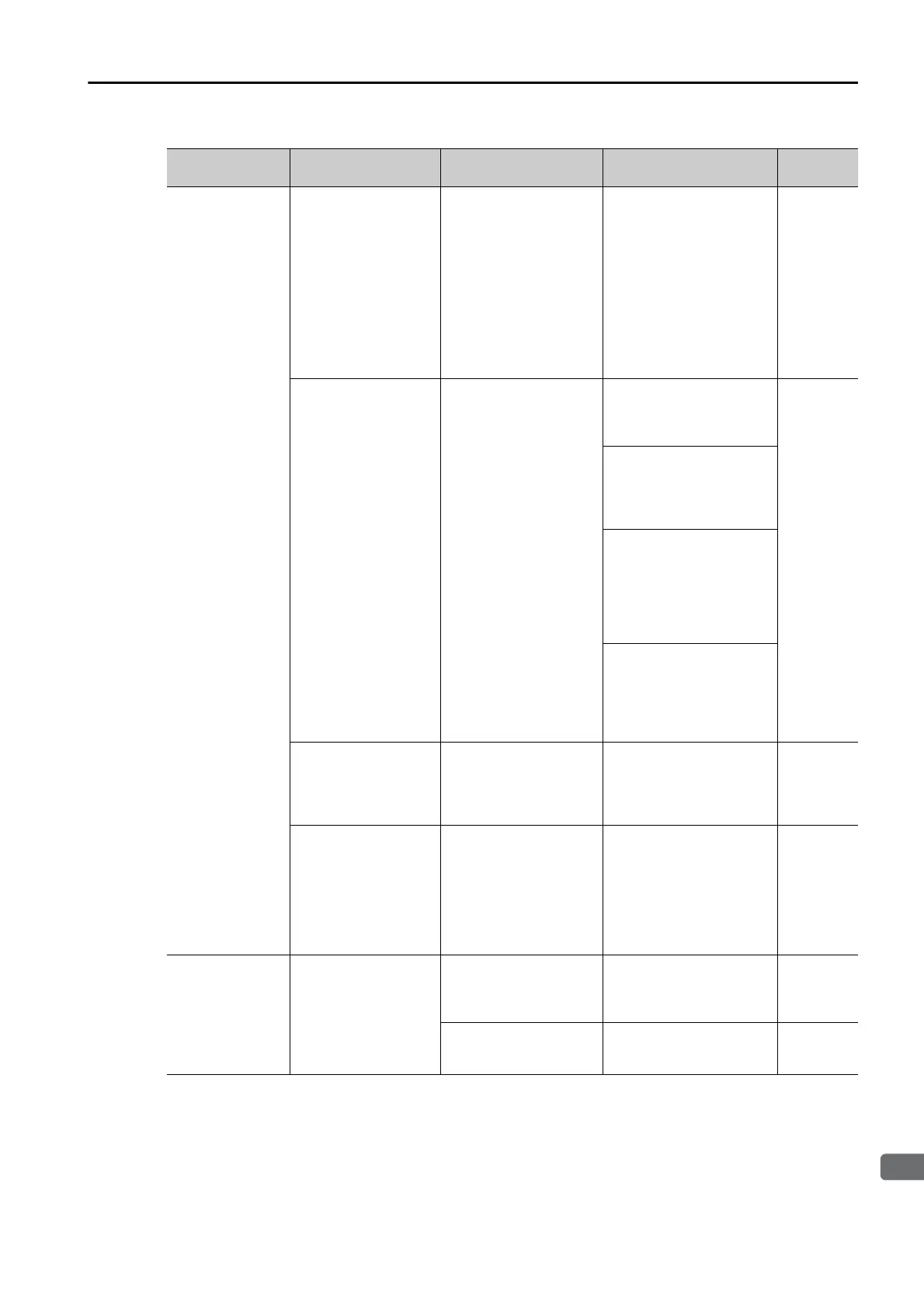

A.E94:

Position Correc-

tion Table

Setting Error

The data set in the

Position Correction

Tab le ( p re -co rrect ion

positions and correc-

tion amounts) is cor-

rupted.

Check the pre-correc-

tion positions and cor-

rection amounts in the

Position Correction

Table.

Initialize the Position Cor-

rection Table.

Restart the SERVOPACK

after initialization. If it

starts normally, set the

Position Correction Table

again.

If the SERVOPACK does

not start normally after ini-

tialization, it may be faulty.

Replace the SERVO-

PACK.

page 3-8

page 3-20

The Position Correc-

tion Table was set

with values outside

the setting range.

Check if the table

entries, pre-correction

positions, correction

amounts, correction

positions (pre-correc-

tion positions+correc-

tion amounts) have

exceeded the setting

ranges.

Set the number of Posi-

tion Correction Table

entries between 2 and

128.

page 3-7

Set pre-correction posi-

tions, correction amounts,

and correction positions

between -2,147,483,648

and 2,147,483,647.

Set the difference

between one pre-correc-

tion position and the fol-

lowing pre-correction

position between

-1,073,741,824 and

1,073,741,823.

Set the difference

between one correction

amount and the following

correction amount

between -1,073,741,824

and 1,073,741,823.

The pre-correction

positions in the Posi-

tion Correction Table

are not set in ascend-

ing order.

Check if the pre-correc-

tion positions are set in

ascending order.

Set the Position Correc-

tion Table so that the pre-

correction positions are in

ascending order.

page 3-7

The correction posi-

tions calculated from

the pre-correction

positions and correc-

tion amounts in the

Position Correction

Table are not in

ascending order.

Check if the correction

positions (pre-correc-

tion positions+correc-

tion amounts) are set in

ascending order.

Set the Position Correc-

tion Table so that the cor-

rection positions are in

ascending order.

page 3-7

A.Ed1:

Command Exe-

cution Timeout

A timeout error

occurred for a

MECHATROLINK

command.

Check the motor status

when the command is

executed.

Execute the SV_ON or

SENS_ON command only

when the motor is not

operating.

–

Check the encoder sta-

tus when the command

is executed.

Execute the SENS_ON

command only when an

encoder is connected.

–

Continued on next page.

Continued from previous page.

Alarm Number:

Alarm Name

Possible Cause Confirmation Correction Reference

Loading...

Loading...