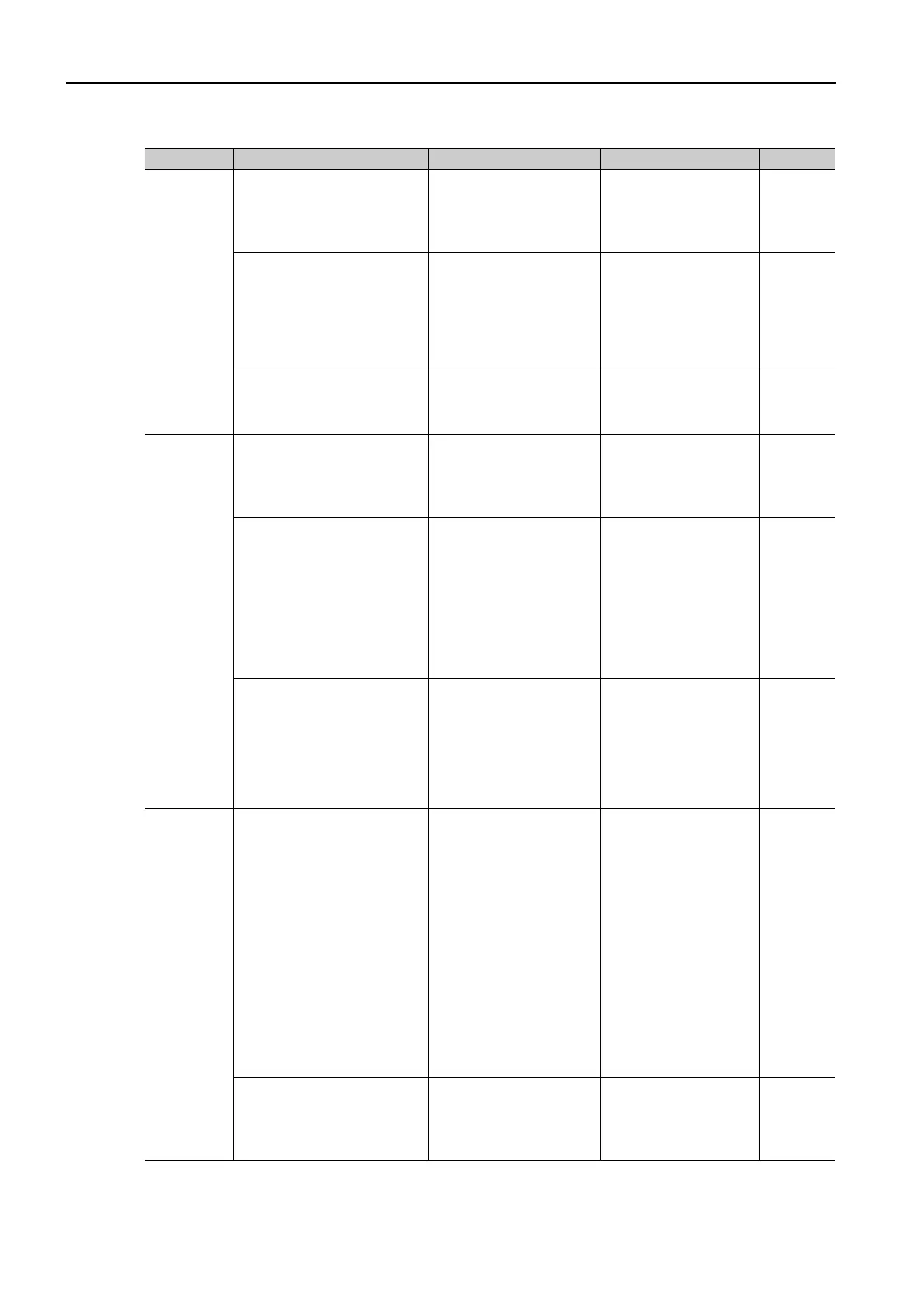

6.3 Troubleshooting Based on the Operation and Conditions of the Servomotor

6-48

Servomotor

Moves with-

out a Refer-

ence Input

A failure occurred in the

SERVOPACK.

–

Turn OFF the power

supply to the servo

system.

Replace the SERVO-

PACK.

–

The count-up direction of the

linear encoder does not

match the forward direction

of the Moving Coil in the

motor.

Check the directions.

Change the setting of

Pn080 = n.X

(Motor Phase

Sequence Selection).

Match the linear

encoder direction and

Servomotor direction.

*

Polarity detection was not

performed correctly.

Check to see if electrical

angle 2 (electrical angle

from polarity origin) at any

position is between ±10°.

Correct the settings for

the polarity detection-

related parameters.

–

Dynamic

Brake Does

Not Operate

The setting of Pn001 =

n.X (Motor Stopping

Method for Servo OFF and

Group 1 Alarms) is not suit-

able.

Check the setting of

Pn001 = n.X.

Set Pn001 = n.X

correctly.

–

The dynamic brake resistor is

disconnected.

Check the moment of

inertia, motor speed, and

dynamic brake frequency

of use. If the moment of

inertia, motor speed, or

dynamic brake frequency

of use is excessive, the

dynamic brake resis-

tance may be discon-

nected.

Turn OFF the power

supply to the servo

system.

Replace the SERVO-

PACK. To prevent dis-

connection, reduce the

load.

–

There was a failure in the

dynamic brake drive circuit.

–

There is a defective

component in the

dynamic brake circuit.

Turn OFF the power

supply to the servo

system.

Replace the SERVO-

PACK.

–

Abnormal

Noise from

Servomotor

The Servomotor vibrated

considerably while perform-

ing the tuning-less function

with the default settings.

Check the waveform of

the motor speed.

Reduce the load so

that the moment of

inertia ratio or mass

ratio is within the allow-

able value, or increase

the load level or reduce

the rigidity level in the

tuning-less level set-

tings.

If the situation is not

improved, disable the

tuning-less function

(i.e., set Pn170 to

n.0) and execute

autotuning either with

or without a host refer-

ence.

*

The machine mounting is not

secure.

Turn OFF the power sup-

ply to the servo system.

Check to see if there are

any loose mounting

screws.

Tighten the mounting

screws.

–

Continued on next page.

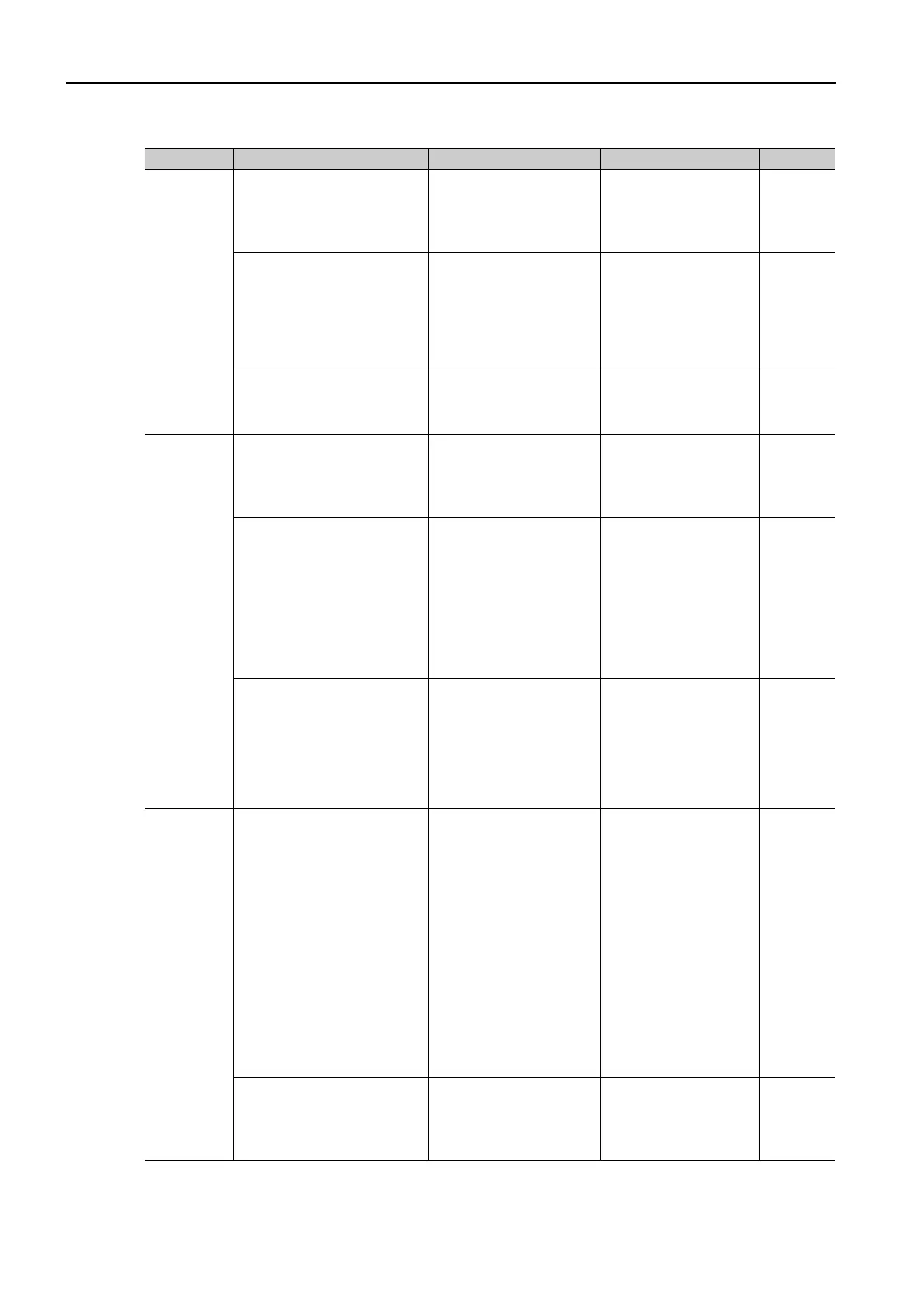

Continued from previous page.

Problem Possible Cause Confirmation Correction Reference

Loading...

Loading...